Hafnium, a rare and valuable refractory metal, possesses unique properties that make it indispensable in various high-temperature applications, including nuclear reactors and aerospace components.

[custom_pricing]

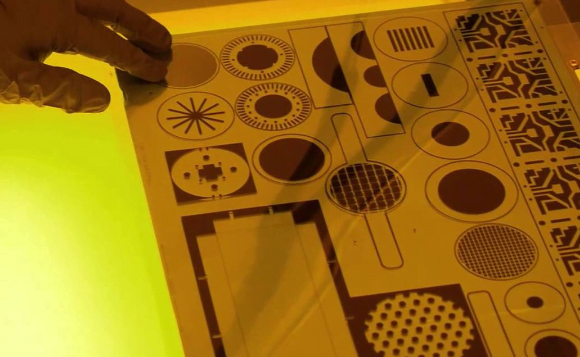

View our Hafnium etching production facility

Types of Hafnium and Alloys: Advantages and Disadvantages in Wet Processing

Hafnium exists in various forms, and alloying it with other elements can enhance specific attributes. Let’s analyze the advantages and disadvantages of each alloy for wet processing:

- Pure Hafnium: Advantages include exceptional corrosion resistance and thermal stability, making it suitable for nuclear applications and aerospace components. However, its high reactivity with certain etchants can pose challenges during the etching process.

- Hafnium-Zirconium (Hf-Zr): This alloy offers improved mechanical properties and reduced neutron absorption cross-section, making it ideal for nuclear reactor control rods. Careful etching is required to prevent surface damage and ensure accurate dimensional control.

- Hafnium-Tungsten (Hf-W): The addition of tungsten enhances mechanical strength and high-temperature performance. This alloy is commonly used in aerospace applications, but the etching process must be carefully controlled to avoid surface deformation.

Metal Etching Hafnium

Metal etching in the wet processing process involves the use of metal etching machines. The choice of etchant, such as Hydrofluoric Acid (HF), Ferric Chloride Etchant, or Cupric Chloride Etchant, impacts the processing difficulty. Let’s explore the key aspects of metal etching for hafnium:

- Etching Difficulty: Hafnium’s reactivity with certain etchants poses challenges during the etching process. Hydrofluoric Acid (HF) is highly corrosive and requires careful handling to achieve precise etching, while Ferric Chloride Etchant offers deep and well-defined patterns. Cupric Chloride Etchant provides controlled etching and is commonly used in electronic applications.

- Precautions: Due to the corrosive nature of etchants, strict safety precautions are essential. Proper ventilation, personal protective equipment, and adherence to handling protocols are necessary to prevent exposure to hazardous fumes and chemical burns.

One of the recommended alkaline etchants for etching Hafnium is a solution of Potassium Hydroxide (KOH). Potassium Hydroxide is a strong base and can effectively etch Hafnium by removing thin layers of the material.

The etching process with Potassium Hydroxide is typically carried out at elevated temperatures to enhance its etching capabilities. The etching rate and selectivity can be controlled by adjusting the concentration of the Potassium Hydroxide solution and the temperature.

It’s important to handle Potassium Hydroxide with care as it is caustic and can cause skin and eye irritation. Proper safety measures, including the use of protective equipment and good ventilation, should be observed when working with Potassium Hydroxide for Hafnium etching.

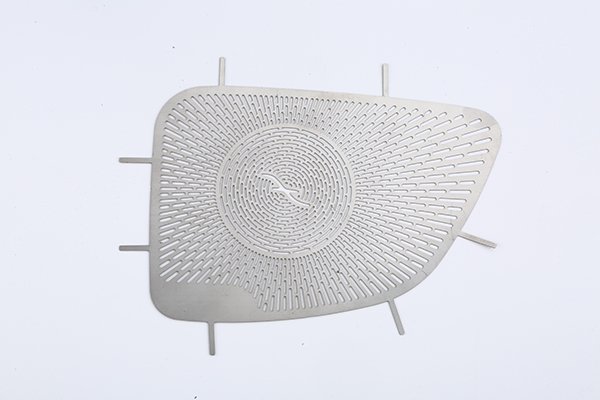

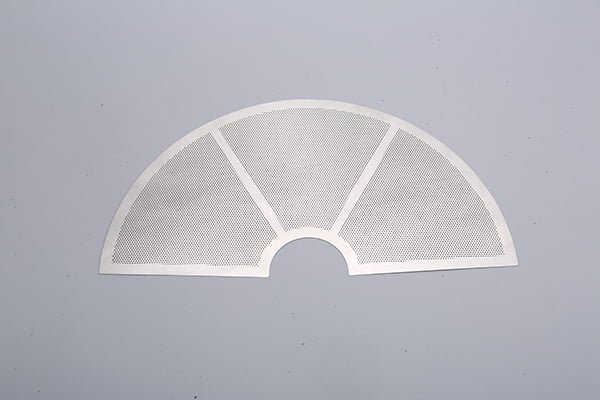

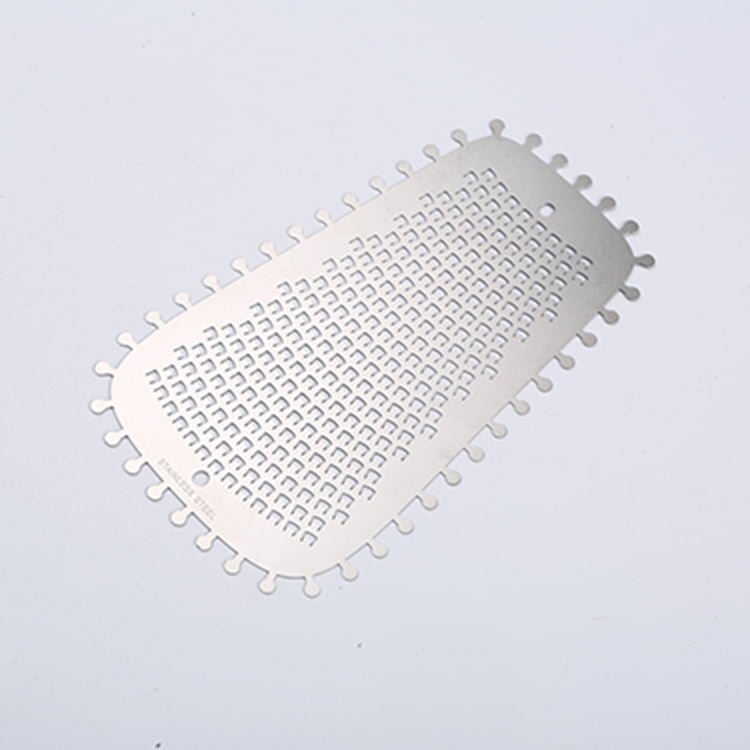

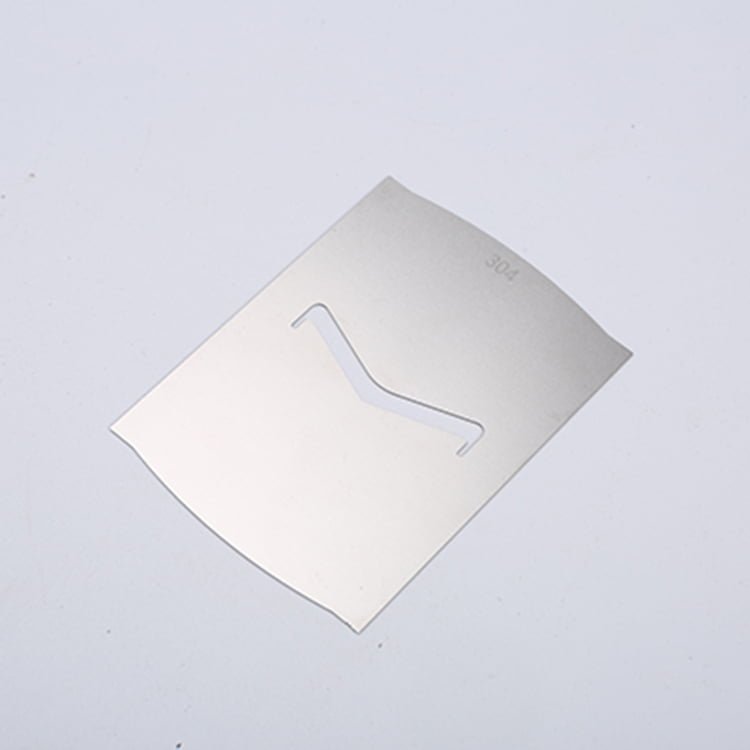

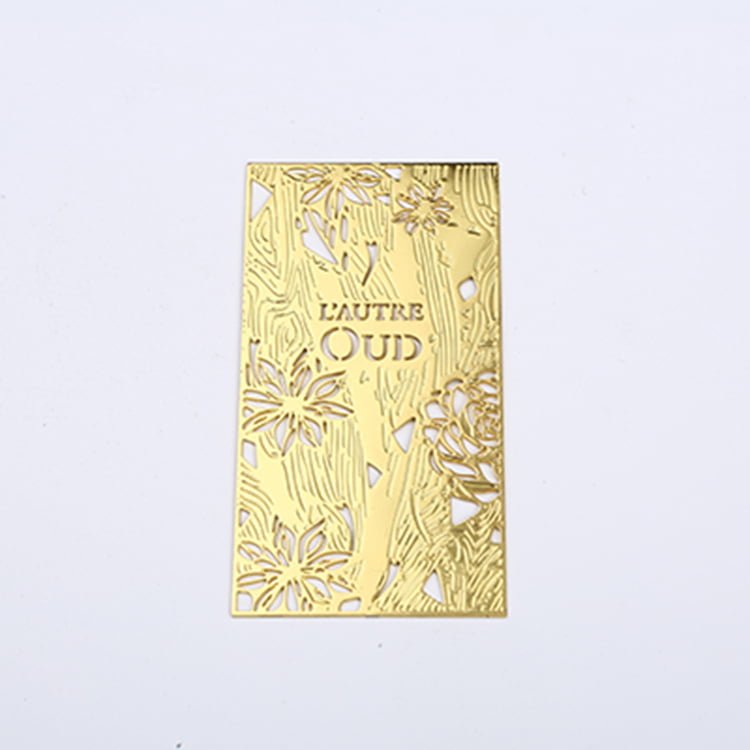

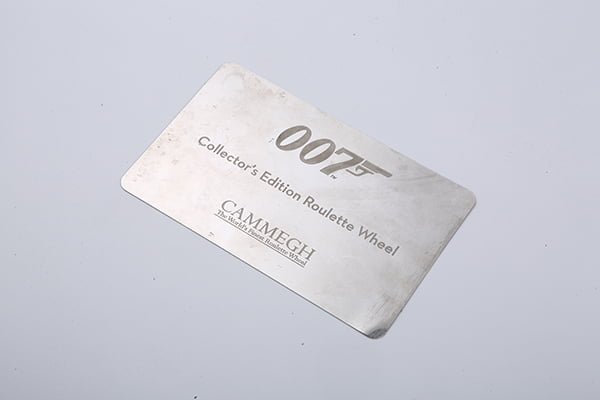

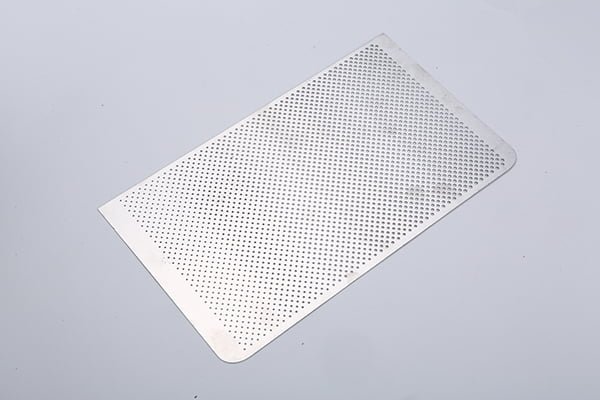

View our metal etching products

Hafnium etching equipment

Photo Etching Hafnium

Photo etching, also known as chemical milling, offers precise and intricate patterns on hafnium surfaces. The process involves using light-sensitive masks to protect specific areas while etching the exposed regions. Let’s explore the key aspects of photo etching for hafnium:

- Processing Difficulty: Photo etching demands exceptional accuracy and control. The photoresist must be carefully applied and developed to ensure accurate pattern transfer onto the hafnium surface. The use of advanced photolithography techniques and skilled expertise is crucial to achieving the desired precision.

- Precautions: Handling of the photoresist requires a clean and controlled environment to prevent contamination. Careful adherence to processing times and temperatures during developing ensures precise pattern transfer without overetching or underetching.

Etching precision-machined hafnium materials requires a comprehensive understanding of the different types and alloys of hafnium, as well as the intricacies of electroforming, surface treatment, metal cleansing, and etching techniques. By selecting the most suitable processes and adhering to stringent precautions, manufacturers and engineers can fully leverage the unique properties of hafnium, contributing to advancements in critical industries such as nuclear technology and aerospace engineering.

how to etch Hafnium?

Etching Hafnium Process Guidelines

| Metal Alloy | Etchant | Etching Temperature (°C) | Etching Concentration (%) | Estimated Etching Depth (microns) | Etching Quality |

|---|---|---|---|---|---|

| Etching Pure Hafnium | Hydrofluoric Acid (HF) | Room temperature | 5% HF | 10-40 | High-quality (smooth) |

| Etching Hafnium-Zirconium (Hf-Zr) | Ferric Chloride Etchant | Room temperature | 10% FeCl3 | 10-50 | High-quality (smooth) |

| Etching Hafnium-Tungsten (Hf-W) | Cupric Chloride Etchant | Room temperature | 10% CuCl2 | 10-50 | High-quality (smooth) |

The values provided are approximate and can vary depending on specific etching conditions, including exposure time and the condition of the hafnium or hafnium alloy surface. Always conduct test etches and adjust parameters as needed to achieve your desired results. Additionally, safety precautions should be followed when handling these chemicals, especially in the case of Hydrofluoric Acid.

If you have metal wet etching Hafnium needs, please feel free to contact us.

FAQs

[FAQS]

Etching Hafnium Samples