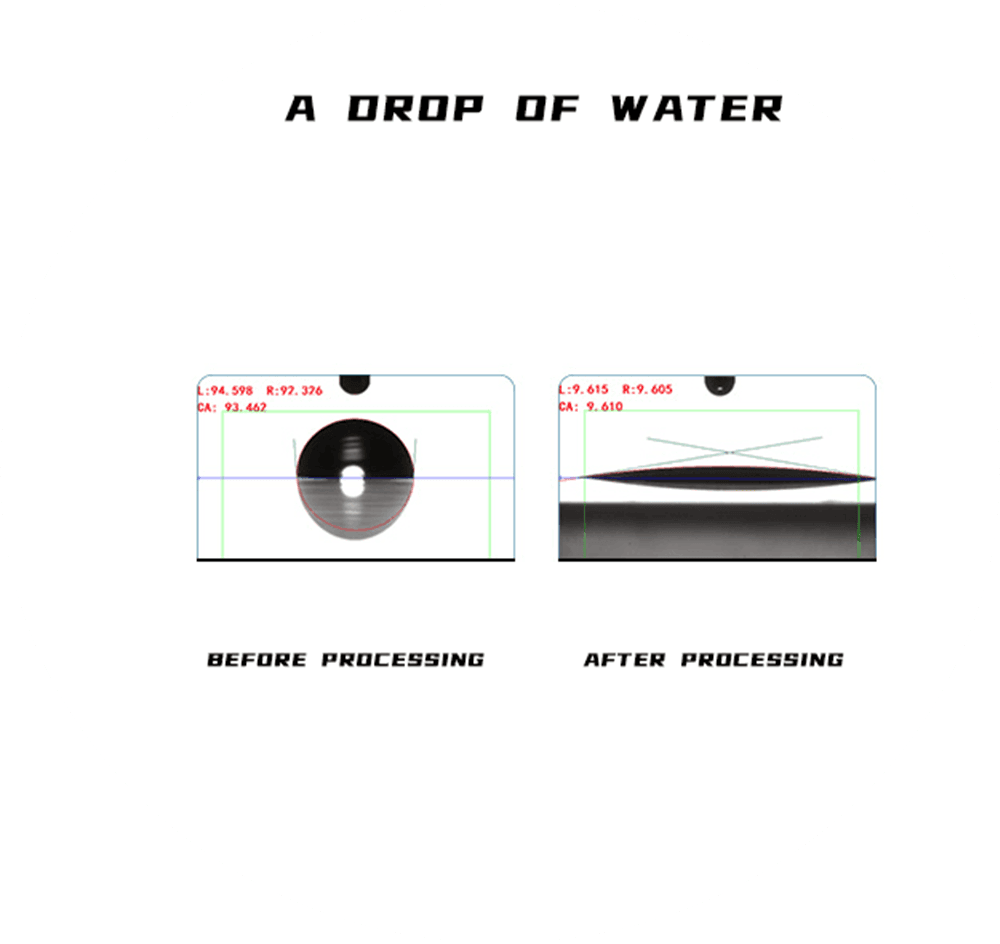

High-precision etching for thin metals (±0.005mm), up to 80% cheaper than laser.

Fixed pricing, no tooling cost, unlimited complexity, fast delivery, low-cost iterations, ±0.005mm precision.

What we can do for your metals business

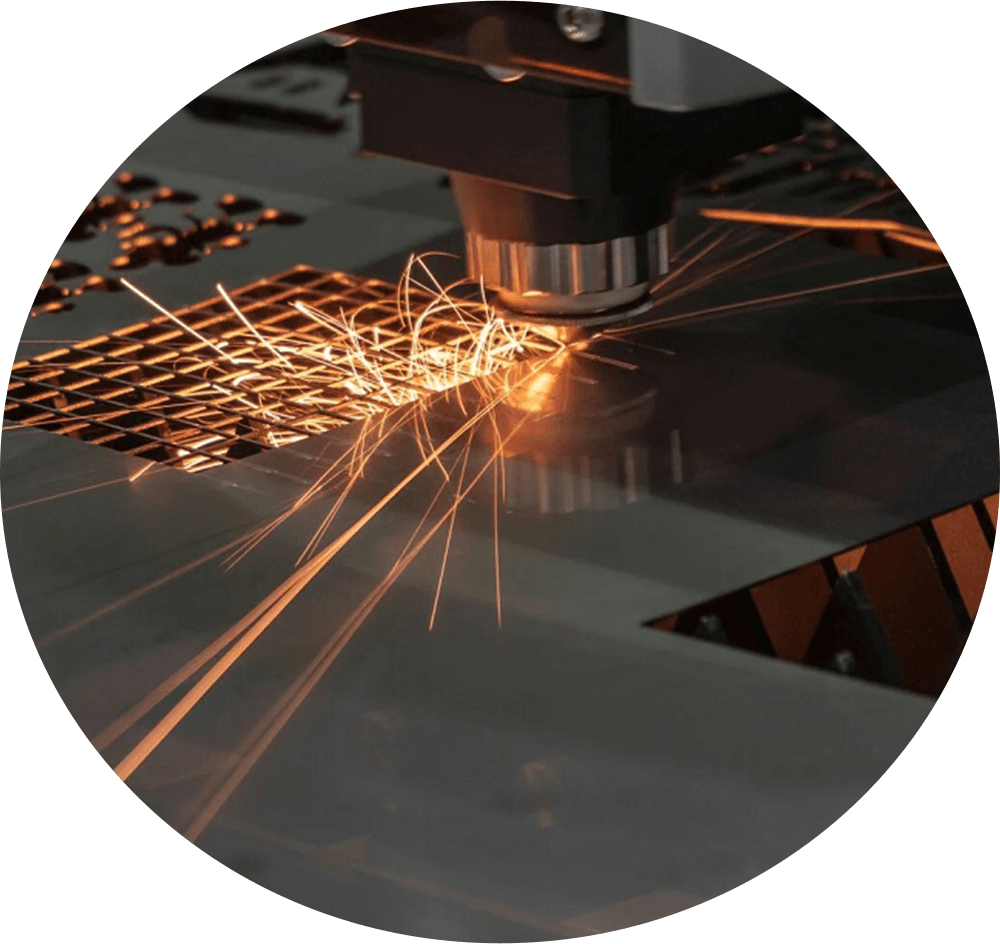

Metal laser cutting Service

We have 5 laser cutting machines available.

Precision: Taking 1mm stainless steel as an example, it can reach +-0.05mm

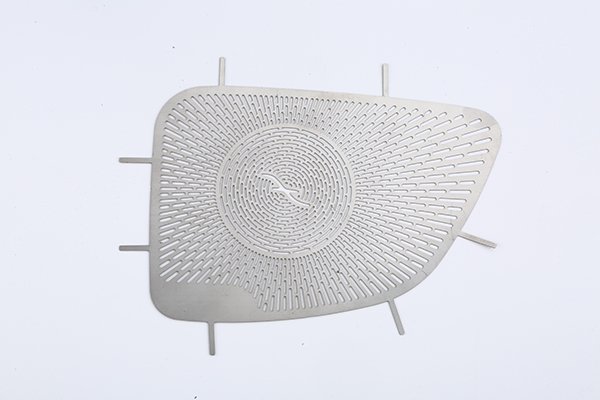

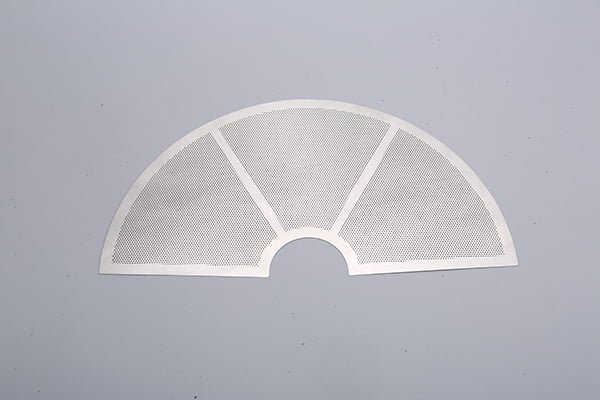

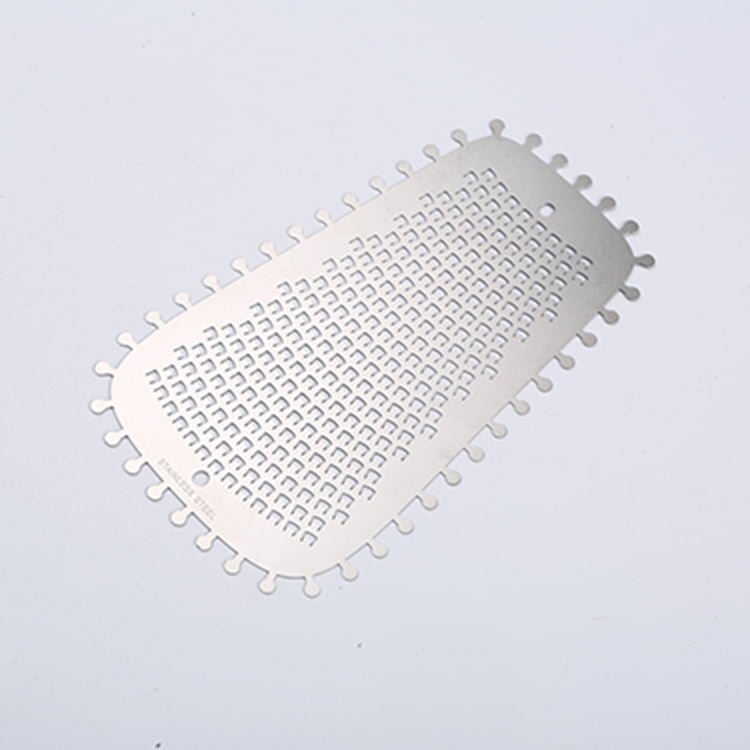

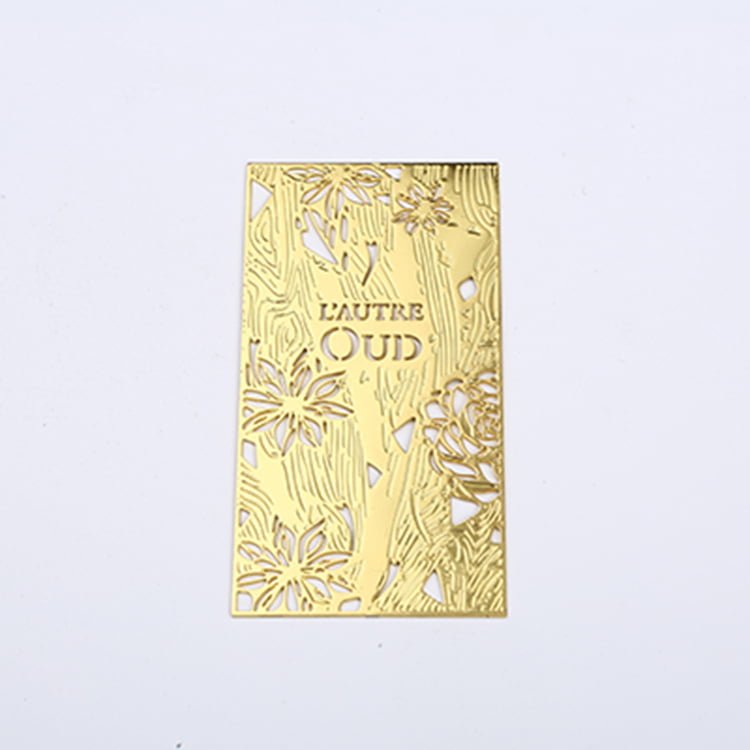

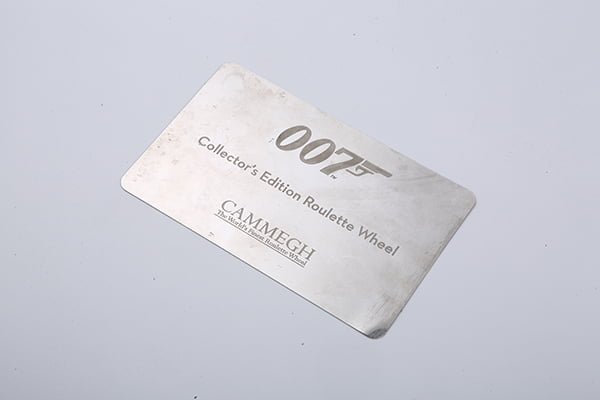

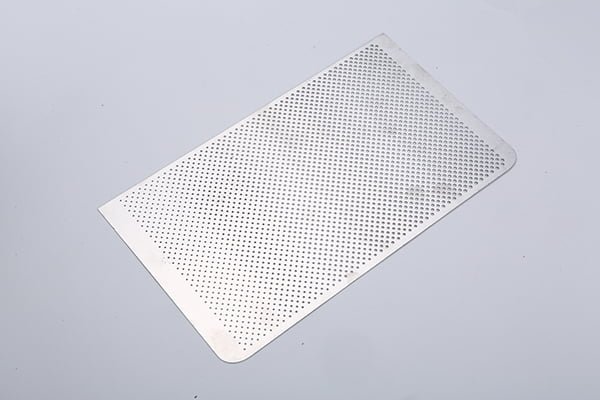

Photo Chemical Etching

We have a 3-story 6,000 square meter etching factory

Precision: Taking 1mm stainless steel as an example, it can reach +-0.005mm

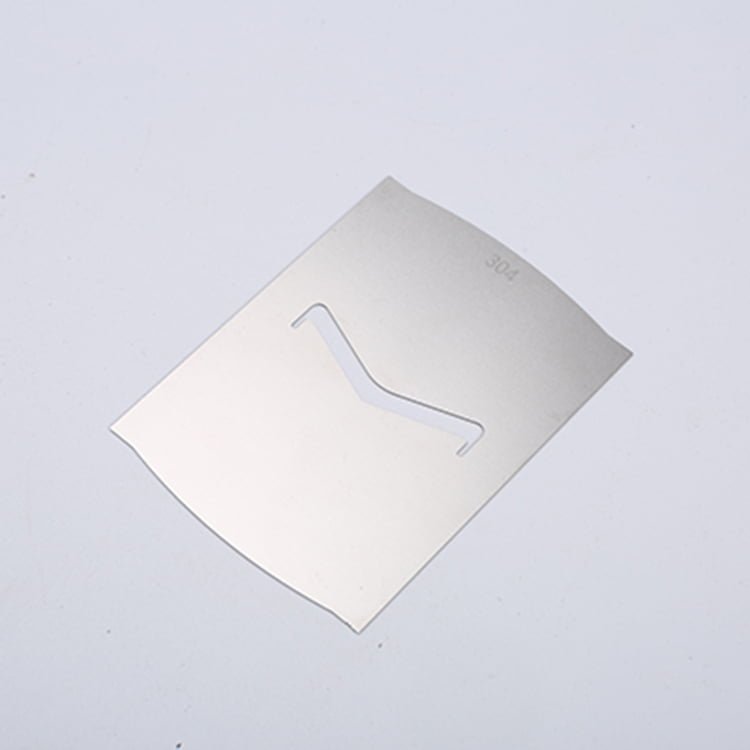

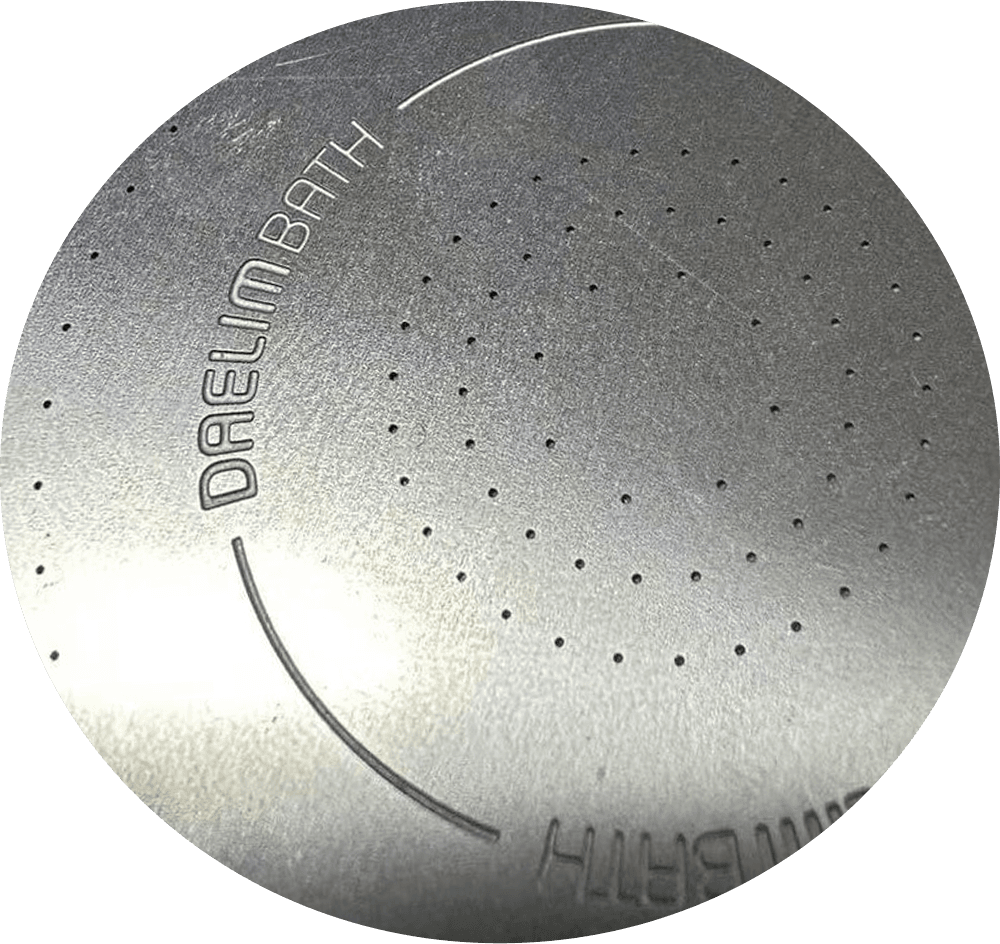

Half & Selective Etching

You could use half etching to create a part number or logo design on an etched component.

In addition, we also have value-added services

Precision prototype customization

Improve design iterations before the product reaches the final stage. We can significantly reduce your experimentation costs.

Prototyping improves product quality by discovering problems and improving manufacturing methods, requirements or specifications before full production begins.

Surface treatment

Plasma surface treatment: enhance the surface adhesion of materials.

Graphene coating enhances heat resistance, conductivity, and more

Electroplating copper, electroplating silver, etc.

Detect one by one

You can receive a test report for each product after we finish production. We will inspect each product.

Quickly understand the etching process, taking SUS 304 stainless steel as an example

WET ETCHED – 15 Years of Precision Metal Etching Expertise

At WET ETCHED, we bring over 15 years of hands-on experience in metal etching and precision microfabrication. Our team is composed of in-house Chemical etching specialists, engraving experts, and CNC machining professionals who work side by side to turn your complex designs into production-ready parts with unmatched accuracy and speed.

Whether you need high-volume components or intricate prototypes, we take pride in identifying the most cost-effective, reliable, and scalable production solution directly from your technical drawings. From stainless steel to copper alloys, and from thin foils to complex 3D surfaces, we optimize each step of the process for performance, durability, and efficiency.

✔ Over 15 Years of Experience

✔ Multidisciplinary Engineering Team

✔ Rapid Turnaround & Consistent Quality

✔ Expert Cost Optimization Based on Your Drawings

✔ Scalable Solutions from Prototypes to Mass Production

Your design. Our precision. One powerful solution.

Choose WET ETCHED — Where expertise meets affordability.

Our custom chemical etching products

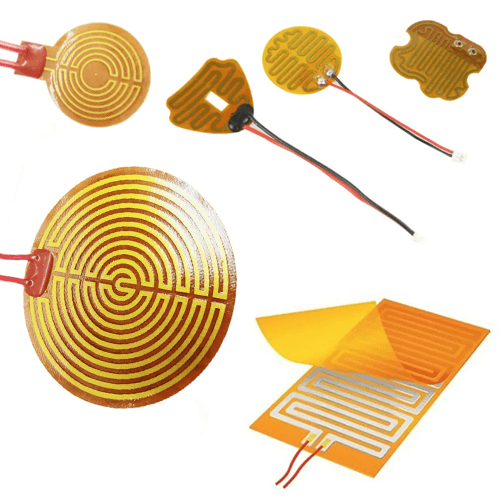

Custom thin film heating elements for flexible, high-performance heating pads

Our Custom Thin Film Heating Elements provide efficient, flexible heating for a variety of applications. We offer material combinations like PI + metal and PET + metal, ensuring optimal performance for industries like automotive, medical, and consumer electronics. With advanced chemical etching techniques, we create precise patterns for even heat distribution. Whether you need a…

Our mastery of metal wet etching

- Wet Chemical Etching Stainless Steel

- Wet Chemical Etching Invar

- Wet Chemical Etching Germanium

- Wet Chemical Etching Gallium Nitride (GaN)

- Wet Chemical Etching Indium

- Wet Chemical Etching Cobalt

- Wet Chemical Etching Tungsten

- Wet Chemical Etching Aluminum

- Wet Chemical Etching Kovar

- Wet Chemical Etching Copper

- Wet Chemical Etching Steel

- Wet Chemical Etching Nickel

- Wet Chemical Etching Platinum

- Wet Chemical Etching Silver

- Wet Chemical Etching Rhodium

- Wet Chemical Etching Hafnium

- Wet Chemical Etching Vanadium

- Wet Chemical Etching Zirconium

- Wet Chemical Etching Titanium

- Wet Chemical Etching Niobium

- Wet Chemical Etching Tantalum

- Wet Chemical Etching Molybdenum

- Wet Chemical Etching Brass

- Wet Chemical Etching Rhenium

Chemical Etching Samples