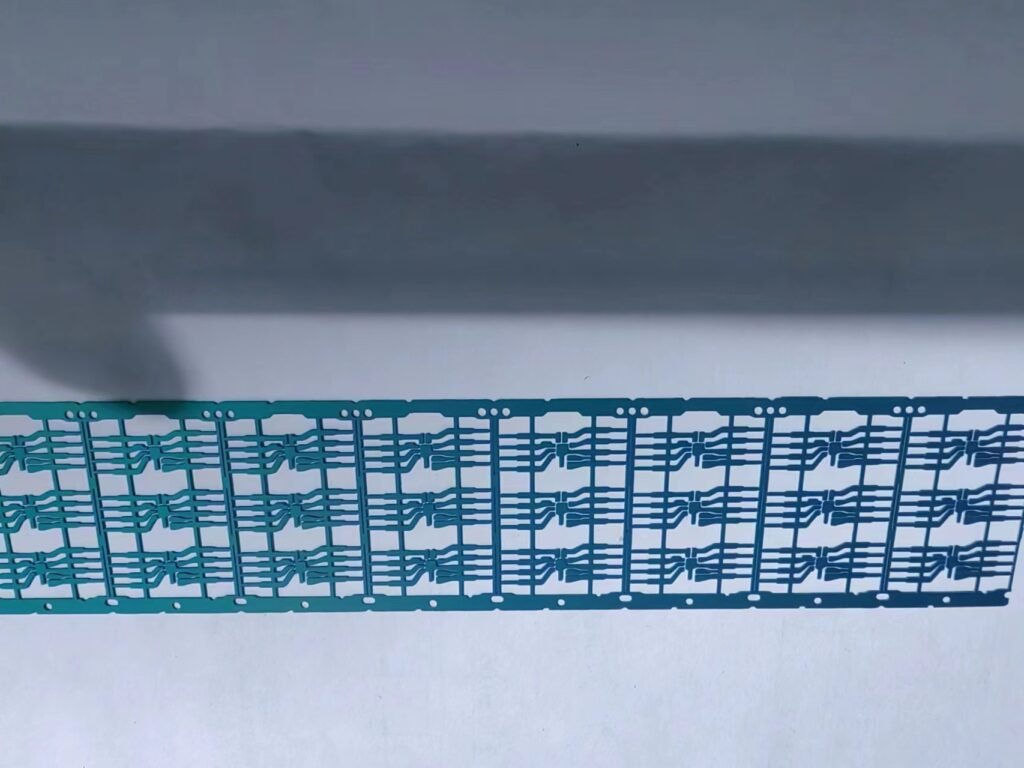

What’s a Lead Frame?

Imagine the tiny skeleton that holds everything together inside your electronic devices. That’s a lead frame—a crucial component that connects the microchip inside your smartphone, smartwatch, or even your car’s ECU (Engine Control Unit) to the outside world.

A simple analogy? Think of it like the metal wiring inside your house—it directs electricity to different rooms just as a lead frame routes signals to different parts of a microchip. Without it, electronics wouldn’t function!

The Difference Between a Reliable Device and a Costly Failure

For most of us, a lead frame is invisible, but the precision in its design can make or break an electronic device. Here’s why:

| Feature | Why It’s Important | Example |

|---|---|---|

| Accuracy (±0.005mm) | Ensures no misalignment in circuits, preventing short circuits or failures. | EV batteries rely on precise lead frames to avoid overheating. |

| Thinness (<0.2mm) | Enables compact and lightweight designs. | Ultra-thin laptops and foldable phones depend on them. |

| Burr-Free Edges | Prevents damage to sensitive microchips. | Medical implants require smooth lead frames to ensure safety. |

🔹 Key takeaway: The more precise the lead frame, the better the performance and reliability of the electronic device.

Etching for High-Performance EV Batteries

According to Tech-Etch, etched lead frames are widely used in electric vehicle (EV) battery modules to ensure stable electrical connections without short circuits. Their process helps reduce power loss and improve energy efficiency in modern EVs (source).

How Lead Frames Enable Next-Gen Devices

From smart wearables to life-saving medical implants, high-precision lead frames push technology forward.

Smartwatches & Wearables

🔹 Problem: Early smartwatches were bulky and had poor battery life.

🔹 Solution: Ultra-thin lead frames (0.1mm) allow for sleeker, lightweight designs.

🔹 Result: Today’s smartwatches, like the Apple Watch and Samsung Galaxy Watch, are thinner and more power-efficient thanks to these innovations.

Medical Implants (Pacemakers & Hearing Aids)

🔹 Problem: Medical devices require extreme reliability—even a tiny flaw in the circuit can be life-threatening.

🔹 Solution: Etched lead frames ensure high accuracy, preventing malfunctions.

🔹 Result: Companies like Medtronic and Cochlear use precision-etched components for safer, long-lasting implants.

📌 Reference: A study from Atotech highlights how etching enhances microelectronics reliability, crucial for medical applications (source).

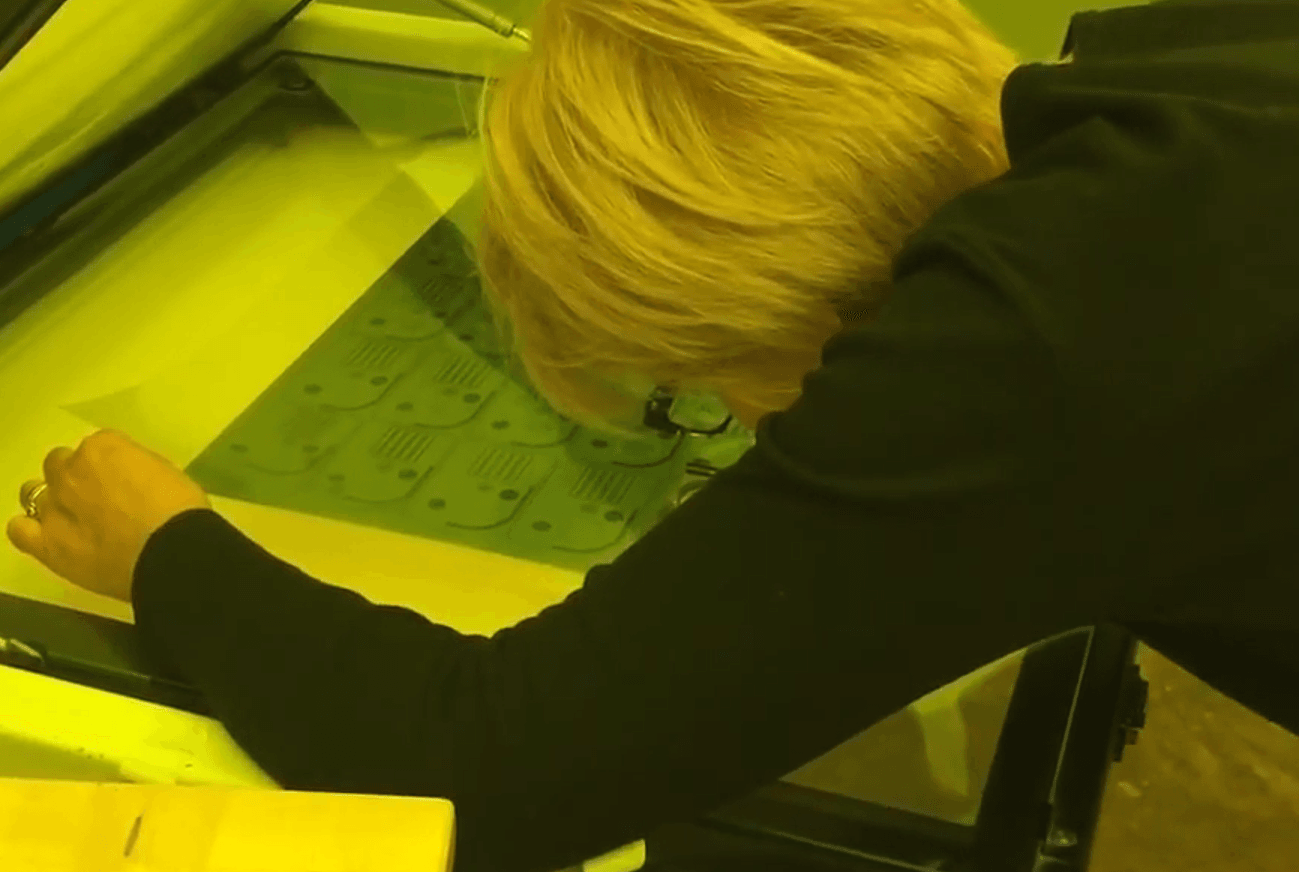

Etching vs. Stamping – The Eco-Friendly Choice

Did you know that how lead frames are made can impact the environment?

| Process | Material Utilization | Waste Production |

|---|---|---|

| Stamping | ~60% usage (40% wasted material) | High (requires secondary processing) |

| Etching | ~90% usage (minimal waste) | Low (less scrap, more efficient recycling) |

🔹 Why it matters: By switching from stamping to etching, manufacturers can reduce material waste by up to 30%, making electronics production more sustainable.

🌍 Future Outlook: AI-Driven Etching & Eco-Friendly Lead Frames

The future of lead frame manufacturing is evolving with:

1️⃣ AI-driven etching machines – Improving precision while reducing chemical usage.

2️⃣ Biodegradable lead frame materials – Researchers are exploring eco-friendly alternatives to traditional metals.

🔹 According to SEMI, the semiconductor industry is shifting towards sustainable manufacturing practices, including greener etching processes (source).

Why This Matters for Everyday Electronics

High-precision etched lead frames are the unsung heroes behind modern devices, making them:

✔ Thinner & more efficient (for wearables, smartphones, and laptops)

✔ Safer & more reliable (for EVs and medical implants)

✔ More sustainable (reducing material waste)

So next time you hold a sleek smartwatch or drive an EV, remember—it’s not just about what’s inside the device, but how it’s made that truly shapes our technology! 🚀