The Challenge: Encoder Failures in Harsh Environments

In industries like food processing, pharmaceutical manufacturing, and marine engineering, rotary encoders are often exposed to high humidity, chemical washdowns, and salt-rich air. Under these conditions, traditional encoder disks made of aluminum or untreated metals can degrade rapidly.

Common failure mechanisms include:

- Pitting corrosion from chemicals or saline exposure

- Oxidation buildup causing signal distortion

- Mechanical fatigue from vibration or heat cycling

According to Heidenhain, encoder failures due to environmental exposure are a leading source of unplanned machine downtime.

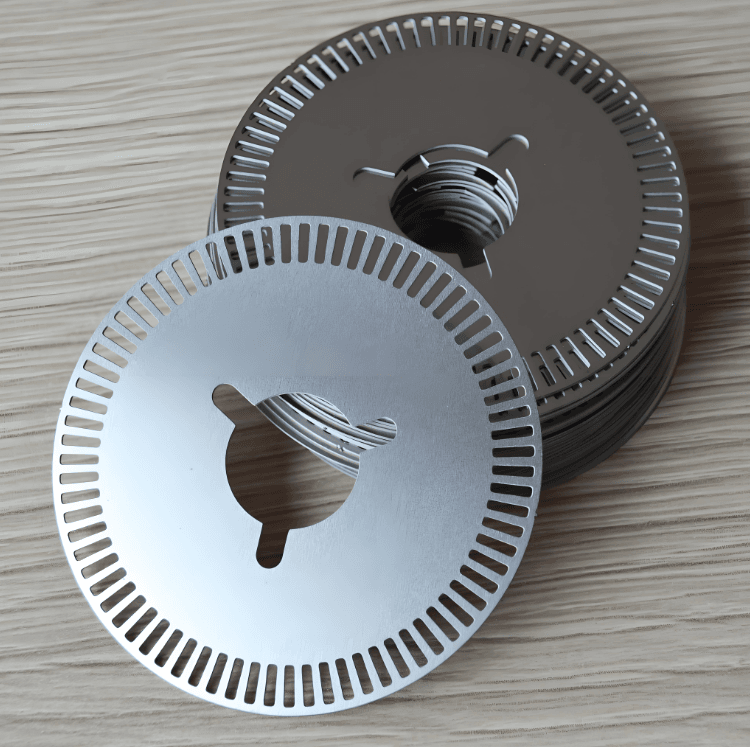

The Solution: Chemically Milled Stainless Steel Gratings

WET Etched offers a high-precision chemical milling service that produces burr-free, stress-relieved encoder disks made from corrosion-resistant stainless steel.

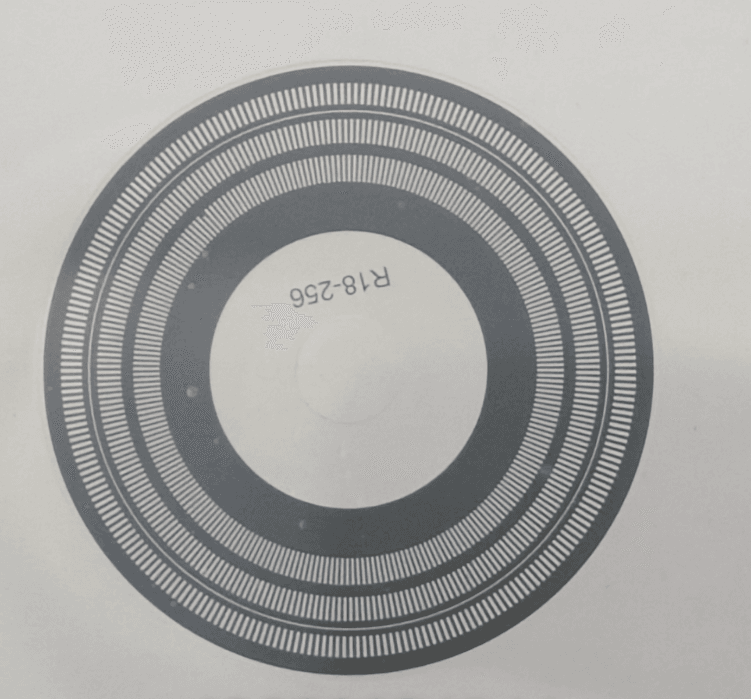

Unlike stamping or laser cutting, chemical milling uses photolithography and chemical etching to create micron-accurate patterns without mechanical deformation. This results in:

- Smooth, burr-free edges to reduce signal noise

- Ultra-precise grating alignment

- Zero mechanical stress—ideal for optical encoders

“Chemical milling offers unmatched mechanical reliability and design freedom for stainless steel encoder parts.”

— Precision Manufacturing Institute, 2024 Journal

Material Comparison: 17-4PH vs. 316L Stainless Steel

| Property | 17-4PH Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Corrosion Resistance | Moderate | Excellent |

| Mechanical Strength | High (can be hardened) | Moderate |

| Stress Cracking Resistance | Moderate | Excellent |

| Post-Milling Finish | Good | Very Smooth |

| Typical Use | Aerospace, heavy machinery | Marine, food, pharmaceutical |

After chemical milling stainless steel, WET Etched applies a passivation process to remove free iron and enhance corrosion resistance. This protective oxide layer ensures long-term durability—even in aggressive chemical environments.

Return on Investment (ROI)

Encoder failure can cost thousands in lost productivity. With WET Etched’s chemically milled stainless steel gratings, you can expect:

- 40%+ longer service life over stamped alternatives

- Reduced replacement frequency and inventory cost

- Minimized machine downtime due to fewer failures

Case Study: Packaging Plant in Ohio

After switching to chemically milled 316L stainless steel gratings from WET Etched, the plant reduced encoder replacements from 6x/year to 1x/year.

- Annual encoder savings: ~$3,200

- Downtime reduction: ~$12,000 per year

“Signal quality stabilized. No more encoder shutdowns during wash cycles.” — Maintenance Manager, Packaging Co.

Final Treatment: Passivation Shield

Following milling, WET Etched applies citric or nitric acid passivation to dissolve surface iron and form a passive chromium-oxide barrier. This enhances oxidation resistance and extends component life—especially in FDA-compliant washdown environments.

When to Replace Your Encoder Gratings

Watch for these red flags:

- Signal jitter or inconsistency

- Visible pitting or discoloration

- Burrs or warping along the disk edge

- Increased frequency of encoder failures

WET Etched recommends inspecting encoder gratings every 6–12 months and replacing at the first sign of degradation in aggressive environments.

Conclusion

If your facility demands high uptime and reliability, investing in chemically milled stainless steel encoder gratings is a smart move. Backed by decades of precision etching expertise, WET Etched’s chemical milling service delivers superior performance in the world’s most demanding industrial environments.