Chemical etching copper offers significant potential for product managers to create innovative, high-quality products across various industries. By understanding the applications, cost structures, sourcing considerations, and future trends, you can leverage this versatile process to gain a competitive advantage and drive new product development. Stay ahead of market trends, embrace innovation, and make informed decisions to optimize the use of copper etching in your business.

Overview of Copper Etching Applications

Key Industries: Electronics, Art, Automotive, and Aerospace

Copper etching has diverse applications across multiple industries. Understanding these sectors will help you identify opportunities for product development.

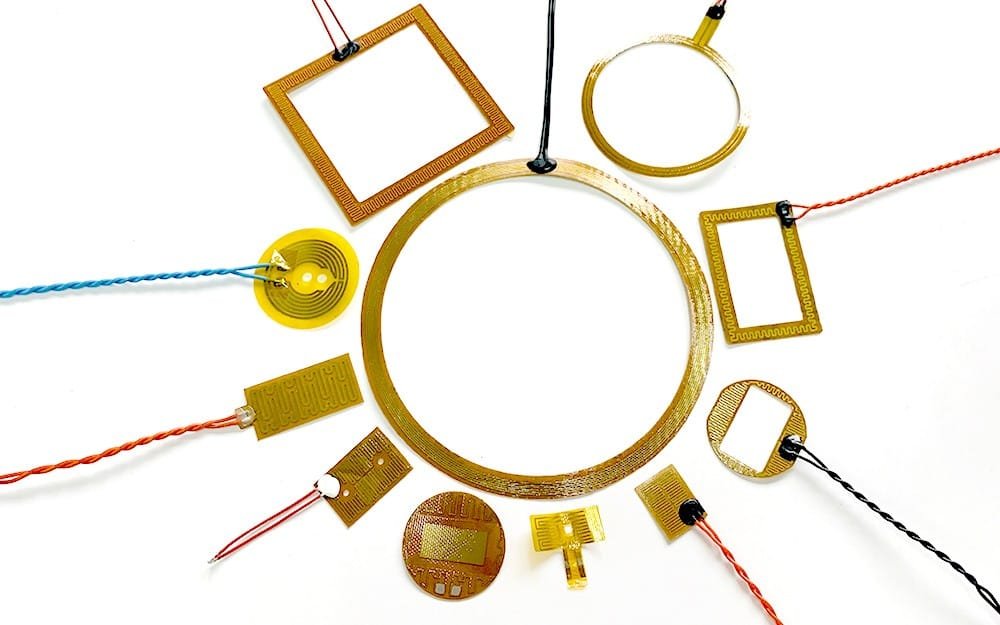

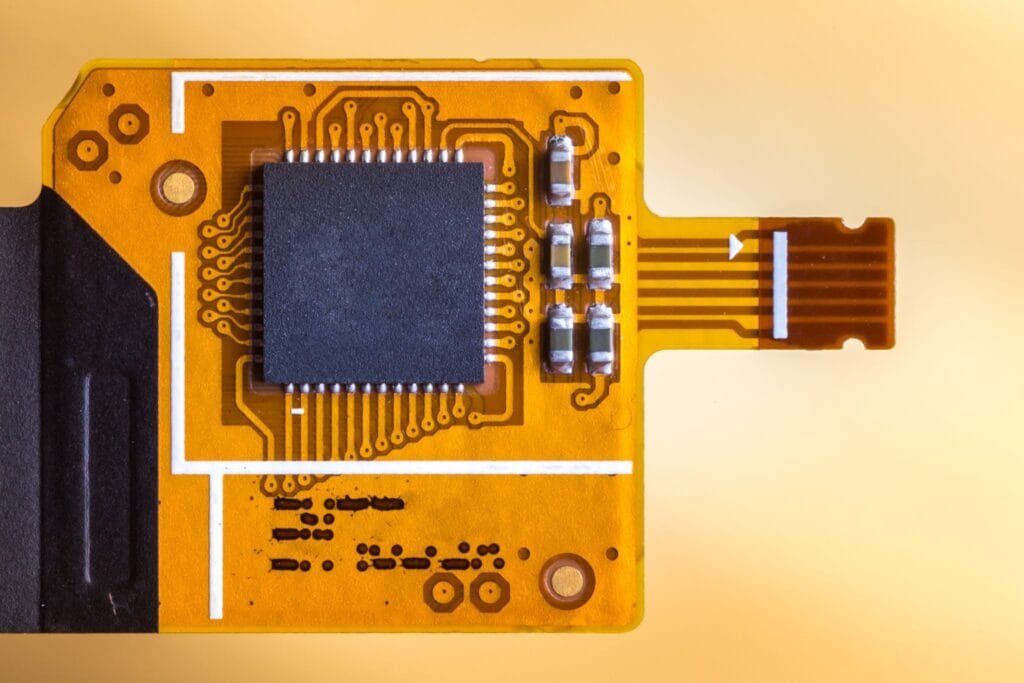

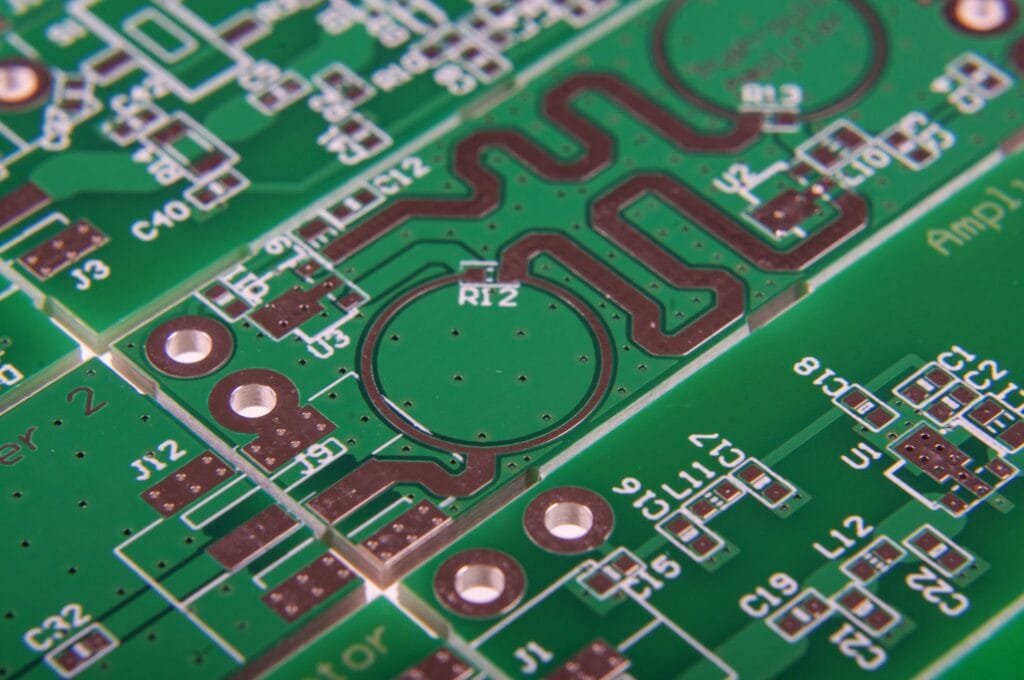

- Electronics: One of the most significant applications of copper etching is in the production of printed circuit boards (PCBs). The high conductivity, flexibility, and corrosion resistance of copper make it an ideal material for the interconnecting traces found in electronic devices.

- Art: Copper etching has long been used by artists to create intricate prints, jewelry, and sculptures. Artists use the etching process to achieve detailed patterns, making it a favorite in fine art and printmaking.

- Automotive: In automotive manufacturing, copper etching is used for sensors, connectors, and other electronic components that require precision and durability in harsh environments.

- Aerospace: Aerospace applications rely on copper etching for components such as heat shields, electrical contacts, and connectors. The material’s resistance to high temperatures and its excellent electrical conductivity make it suitable for demanding conditions.

Case Studies of Successful Products Using Etched Copper

- Printed Circuit Boards (PCBs): Companies like Intel and Qualcomm rely on precise copper etching for PCB production, allowing for high-density circuits in electronic devices.

- Art Prints: Artists such as Rembrandt have used copper etching techniques to produce detailed artworks. Modern artists continue to use this process for limited-edition prints and sculptures.

- Automotive Sensors: Companies like Bosch utilize copper etching to create sensors used in vehicles, ensuring precision and reliability.

Market Size and Growth Projections

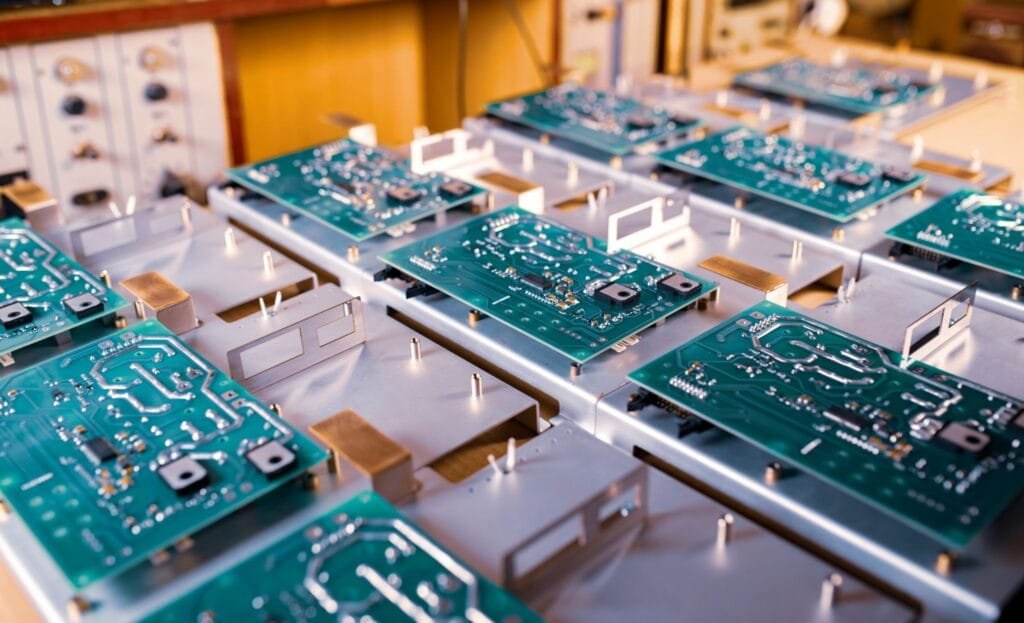

The copper etching market has seen steady growth due to increased demand for electronics, automotive innovations, and aerospace technologies. According to market research, the global PCB market is projected to reach over $80 billion by 2027, driven by the growing need for smaller, faster, and more efficient electronic devices. This trend will likely propel further advancements in copper etching techniques.

Cost Analysis and ROI

Comparing Etching with Other Manufacturing Methods

When considering copper etching for product manufacturing, comparing the costs to other methods, such as laser cutting, CNC machining, or stamping, is essential for making an informed decision.

| Method | Advantages | Disadvantages |

|---|---|---|

| Chemical Etching | High precision, cost-effective for complex designs | Requires chemical handling, environmental concerns |

| Laser Cutting | High speed, clean cuts, minimal material waste | Expensive equipment, limited to certain designs |

| CNC Machining | Ideal for complex 3D shapes, highly customizable | Higher labor and machine costs |

| Stamping | Best for high-volume production | Limited design complexity, high setup costs |

Etching stands out in applications that require intricate details and precision at a lower cost, especially for prototyping and small to medium production runs.

Factors Affecting Cost: Materials, Labor, and Equipment

- Materials: Copper costs fluctuate based on market demand, quality, and alloy composition. The price of the chemical etchants (e.g., ferric chloride, ammonium persulfate) also affects production costs.

- Labor: Labor costs for etching vary depending on the complexity of the designs, the number of steps involved, and whether automation is used in the process.

- Equipment: Investment in etching equipment is relatively low compared to laser or CNC machines, making it a cost-effective option for smaller businesses or prototype development.

Calculating ROI for Etching-Based Products

To calculate the return on investment (ROI) for etching-based products, consider the following factors:

- Initial Equipment Investment: Consider the upfront costs of etching equipment and setup.

- Production Costs: Account for material costs, labor, and chemicals.

- Volume: Etching is particularly cost-effective for medium-volume production runs. As production volume increases, ROI improves due to lower per-unit costs.

Sourcing and Supply Chain Considerations

Finding Reliable Suppliers for Copper and Etching Materials

Sourcing quality copper and etching materials is critical to the success of your production. Here are some factors to consider:

- Copper Suppliers: Establishing relationships with reliable copper suppliers ensures that you receive consistent quality at competitive prices. Consider global suppliers with strong reputations in the electronics and manufacturing industries.

- Etching Chemicals: Work with suppliers who provide high-purity etching chemicals and resist materials. It’s essential to ensure that the chemicals meet the required standards for your applications.

Managing Lead Times and Quality Control

Lead time management is essential for maintaining production schedules. Working with suppliers who can deliver on time is crucial to keeping your project on track. Implementing robust quality control systems, including testing materials and inspecting etched products, ensures that the end products meet quality standards and specifications.

Global Market Dynamics and Sourcing Strategies

Global supply chain dynamics play a significant role in sourcing materials. Geopolitical factors, such as trade restrictions or tariffs, can impact copper prices and availability. Diversifying your supplier base and considering local sourcing options may help mitigate risks and stabilize your supply chain.

Innovation and Competitive Advantage

How Etching Can Differentiate Your Product

In a competitive market, differentiation is key. Chemical etching can give your products a competitive edge by enabling intricate designs, reducing manufacturing costs, and offering unique features not easily achieved by other methods.

For example, in the electronics industry, companies that use etching to create compact, high-density PCBs can offer products with more features in smaller devices, a critical factor in consumer electronics.

Collaborating with R&D to Explore New Applications

Work with your research and development (R&D) teams to explore new applications for copper etching. Potential areas for innovation include:

- Flexible electronics: Copper etching can be used to create thin, flexible PCBs that can be integrated into wearable devices.

- Sensors and IoT devices: Etching can be employed to manufacture small, precise sensors used in IoT devices and smart technologies.

Protecting Intellectual Property in Etching-Based Designs

As copper etching enables the creation of custom designs, it’s essential to protect intellectual property (IP). Work with legal teams to patent unique designs or manufacturing processes that use copper etching, ensuring your innovations remain exclusive to your business.

Future Trends and Opportunities

Emerging Technologies in Copper Etching

The future of copper etching lies in advancements like laser etching, additive manufacturing, and direct-write technologies. These innovations will offer faster production speeds, finer resolution, and more complex designs. Additionally, the use of nano-inks and 3D printing in combination with copper etching will enable the creation of even more intricate and compact components.

Sustainability and Eco-Friendly Etching Solutions

Environmental considerations are driving demand for sustainable etching solutions. Innovations such as water-based etchants, closed-loop recycling systems for chemicals, and non-toxic alternatives to traditional etchants are reducing the environmental footprint of copper etching. Adopting these eco-friendly practices can enhance your company’s sustainability profile and appeal to environmentally-conscious customers.

Expanding into New Markets and Industries

As technology evolves, copper etching is expanding into new markets such as flexible printed electronics, wearable tech, smart textiles, and automotive electronics. Exploring these new opportunities will allow your business to tap into emerging trends and expand your market reach.