Yes, there is significant potential for Photo Chemical Machining (PCM) in the future. As industries continue to demand more precise and complex components, PCM offers advantages such as high accuracy, fine detail, and the ability to work with various materials. Its applications in sectors like aerospace, electronics, and medical devices are likely to expand, particularly as the push for miniaturization and lightweight components grows. Additionally, advancements in photoresist materials and processing techniques could further enhance its capabilities, making PCM an attractive option for manufacturers.

Table of Contents

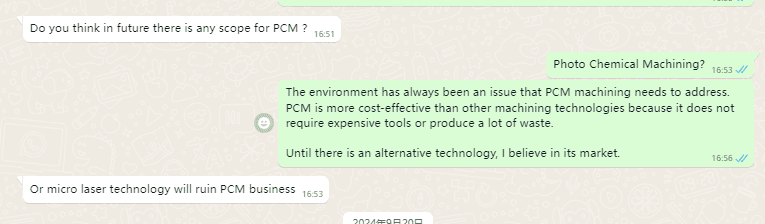

Or micro laser technology will ruin PCM business

Micro laser technology could certainly impact the PCM business by offering alternative solutions for precision machining. Lasers provide advantages like reduced material waste, faster processing times, and the ability to handle complex geometries. However, PCM has its unique strengths, such as the ability to create intricate designs without thermal distortion. The two technologies may coexist, each serving specific applications, but competition will likely drive innovation in both fields. Ultimately, it may come down to the specific needs of industries and the materials involved.

I have been involved in the sales of laser cutting machines and laser engraving machines.

That was in 2021. Among the equipment I know, the price of the equipment that can achieve the accuracy of PCM equipment is very high.

Maybe they can replace some PCM business, but for PCB, aluminum PCB, copper, these businesses used in PCB production, PCM still occupies an irreplaceable position.

Can they coexist?

Yes, PCB chemical etching and chemical milling can coexist. Each technology has distinct advantages that make them suitable for different applications. For example, chemical etching is often favored for creating fine details and intricate patterns, while chemical milling is typically used for reducing the thickness of larger metal components and producing lightweight parts.

As industries evolve, there may be niches where each method shines, and companies might even use both technologies depending on specific project requirements. Collaboration and integration of technologies could also lead to innovative solutions that leverage the strengths of each method.

How do you view the relationship between the two?

The relationship between PCB chemical etching and chemical milling is one of complementary strengths. While they target different aspects of metal processing, both are integral to modern manufacturing. PCB chemical etching excels in precision and fine detail, making it ideal for electronics, while chemical milling focuses on efficiency and material removal for larger components.

As industries demand more versatile and customized solutions, these processes can enhance each other. For example, a manufacturer might use etching for intricate designs on a PCB and milling for structural components, creating a synergy that meets diverse needs in the production line.