Horn mesh etching is a fascinating technique used to create intricate patterns on metal surfaces, such as stainless steel or titanium, by using acids or plasma. Whether you are a hobbyist, student, or simply curious about how metals are patterned for various industrial applications, this guide will break down the process of horn mesh etching in an easy-to-understand way. We’ll explore real-world examples, compare the process to a simple analogy, and even touch on safety with non-toxic alternatives for DIY projects.

What is Horn Mesh Etching?

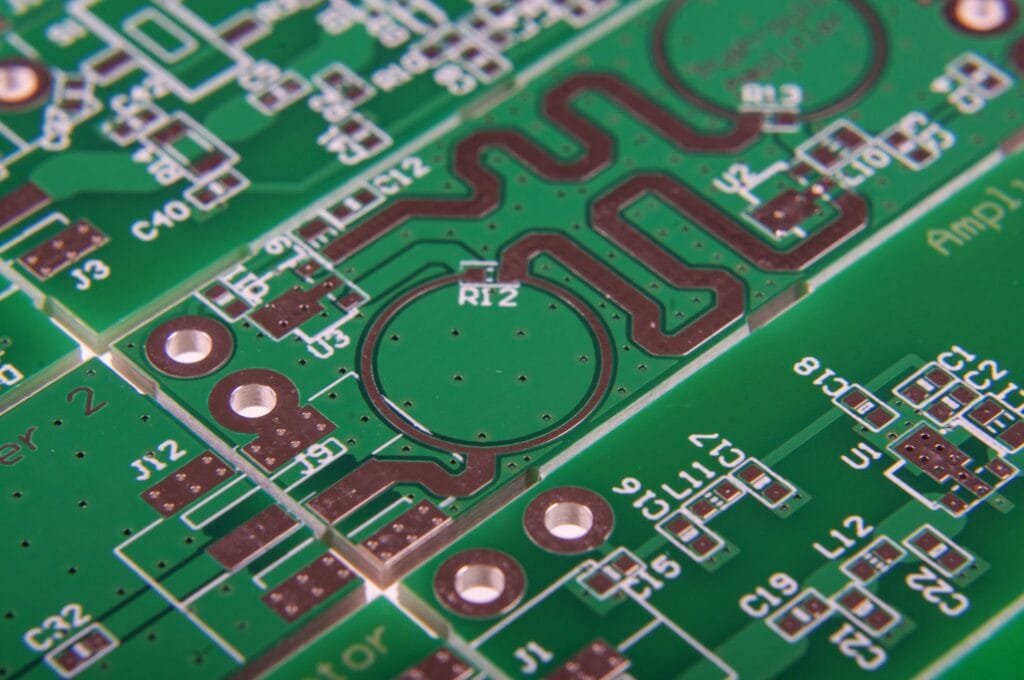

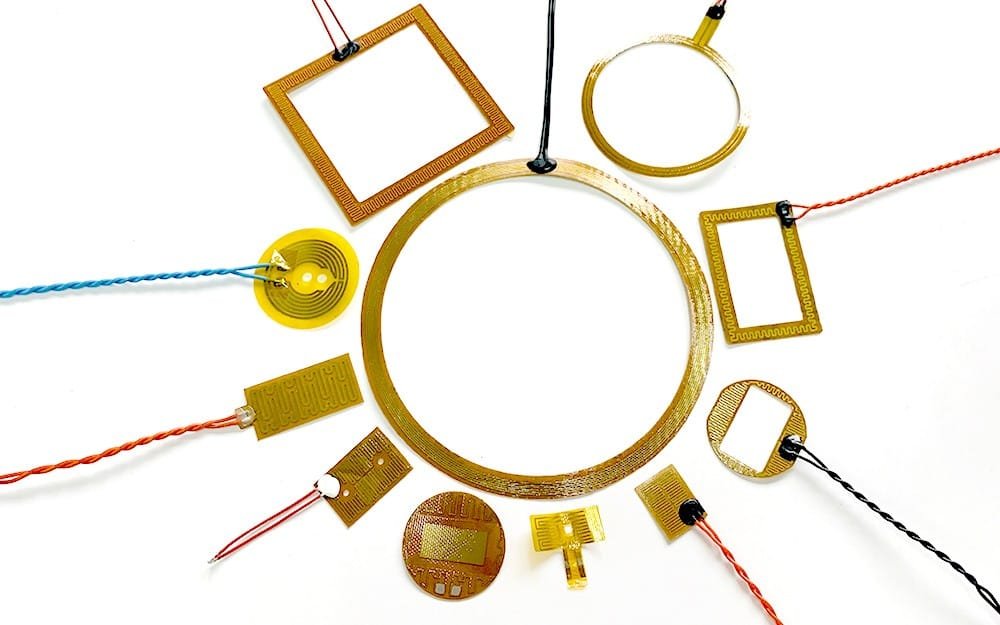

Horn mesh etching is a precision method used to pattern or create intricate designs on metal sheets, such as stainless steel, titanium, or even aluminum, primarily for functional or decorative purposes. This process typically involves using an acid or plasma to etch the design into the metal’s surface, creating patterns like mesh grids or custom textures. The etching can be done in different ways, but the most common method is using an acid-resistant mask to protect certain areas while the etchant works on the unprotected areas, producing the desired pattern.

Real-World Examples of Horn Mesh Etching

Horn mesh etching has a wide variety of real-world applications across different industries. Here are a few examples:

- Decorative Architectural Panels: Etching can create beautiful, intricate patterns on metal panels used in architectural designs, such as building facades, fences, or room dividers.

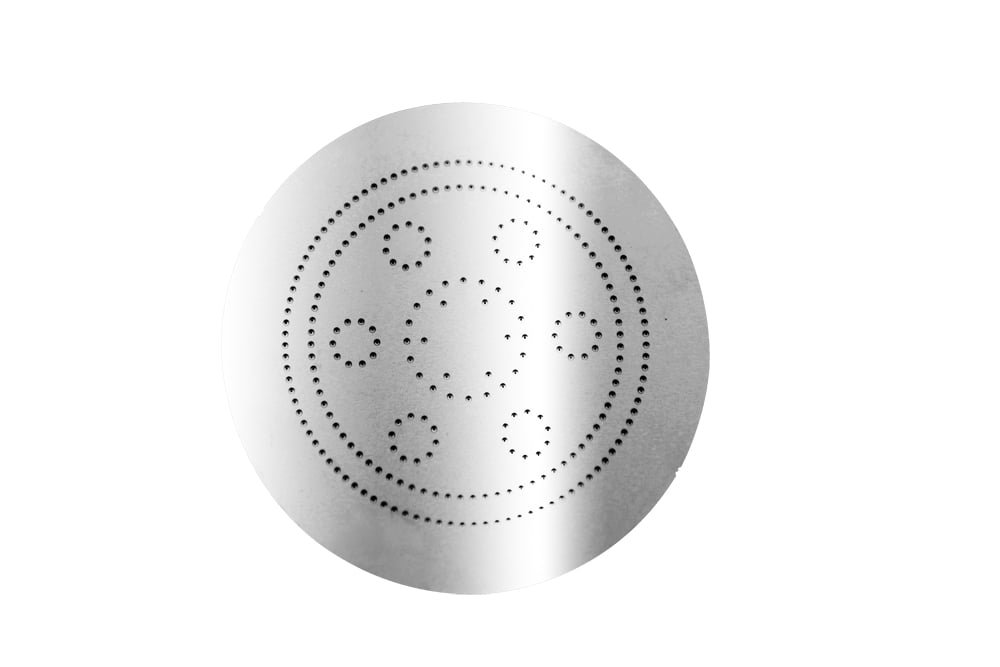

- Speaker Grilles: Many speaker manufacturers use horn mesh etching to create perforated metal grilles. These grilles provide protection while allowing sound to pass through.

- Automotive Air Filters: Horn mesh etching is also used in automotive industries to design filters that need both strength and airflow optimization. The etched patterns help to improve the efficiency of the filters without compromising their structural integrity.

Step-by-Step Analogy: Drawing with Acid

To understand the process of horn mesh etching, think of it as drawing with acid. Here’s a step-by-step analogy of the process:

- Design the Pattern: First, you create or select a pattern. This could be a mesh, grid, or a custom design that you want to apply to the metal surface.

- Masking: Similar to drawing with a pencil on paper, you apply an acid-resistant mask (like a coating or tape) to the areas of the metal sheet that should remain untouched. The design is either drawn on the mask or transferred onto it.

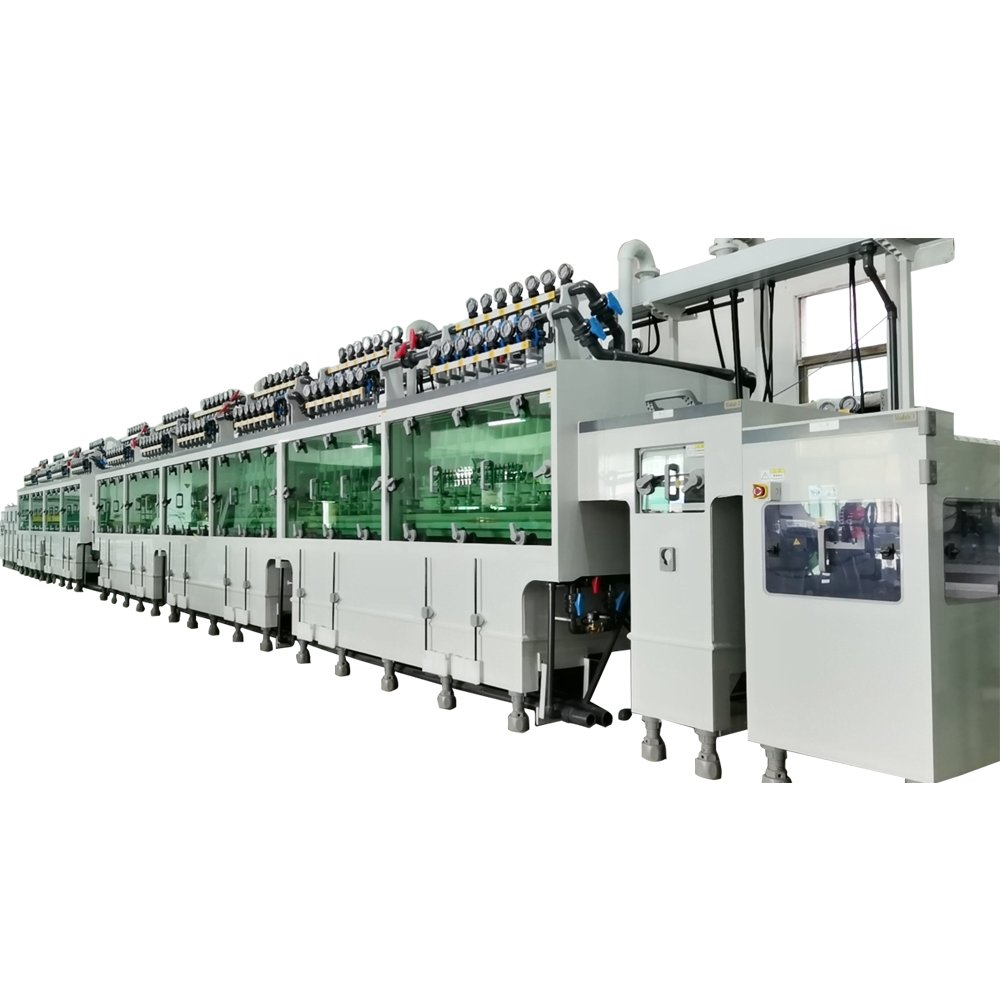

- Submerging in Etchant: After the mask is applied, you immerse the metal sheet into an etching solution (often an acidic solution like ferric chloride or nitric acid). This is where the acid works to etch away the unprotected areas, much like drawing with a sharp tool but with the precision of a chemical reaction.

- Cleaning the Residue: Once the etching is complete, the metal is cleaned, and the acid-resistant mask is removed, revealing the intricate pattern on the surface.

It’s essentially like creating a design by drawing, but instead of using ink or pen, you’re using acid to carve your patterns into the material.

Safety Spotlight: Non-Toxic Etching Alternatives

Safety is always a priority when working with any etching process. Traditional methods often use strong acids like nitric acid, which can be hazardous. However, for DIY enthusiasts and hobbyists, there are non-toxic alternatives that you can use to create safe etching projects at home.

- Vinegar-Based Solutions: One common and safer etching solution is vinegar-based solutions. This solution is less harmful than traditional acids and is often used in small-scale or DIY projects.

- Baking Soda: If you spill vinegar-based etchants, baking soda can be used to neutralize the acid and make cleanup easier.

It’s important to always wear gloves, goggles, and work in a well-ventilated area even when using safer alternatives to prevent skin or eye contact.

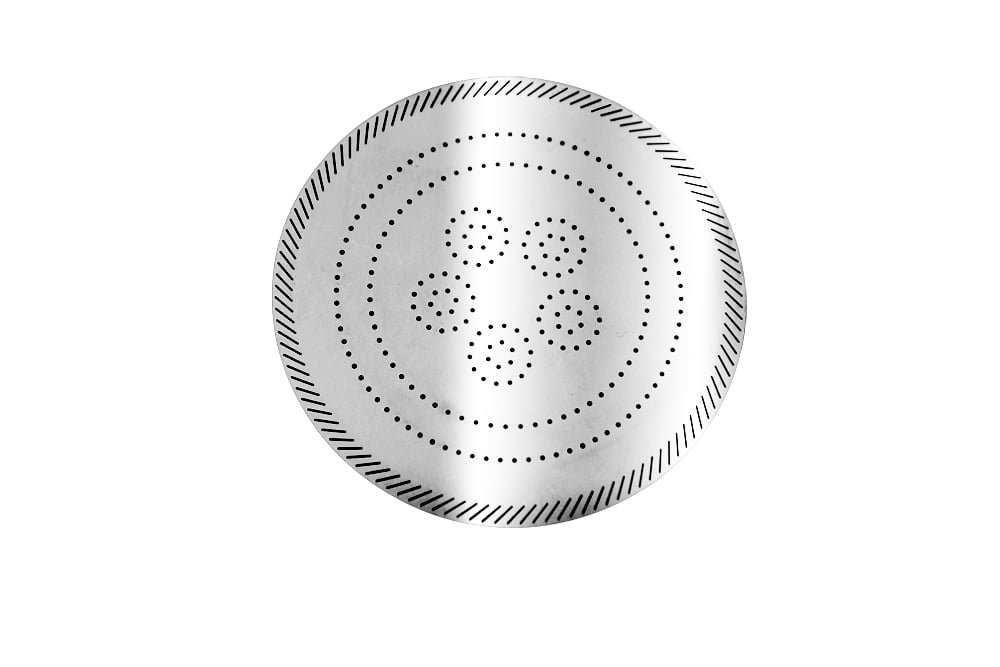

Visual Aid: Raw vs. Etched Horn Mesh for Airflow Optimization

Here’s a side-by-side comparison to visualize the impact of horn mesh etching on airflow optimization in automotive air filters:

| Raw Metal Sheet | Etched Horn Mesh |

|---|---|

| A plain metal sheet without any perforations or patterns. | After etching, the metal sheet has intricate mesh patterns that allow for optimal airflow while maintaining the strength of the material. |

In applications like automotive air filters, the etched pattern on the metal improves airflow efficiency by reducing the weight and increasing the surface area without compromising on the structural integrity of the material. The etched design enables air to pass through more freely while still filtering out impurities.

Summary

Horn mesh etching is a versatile and efficient way to create intricate, functional patterns on metal surfaces. Whether used for decorative architectural panels, speaker grilles, or automotive air filters, this process has widespread applications across various industries. The technique can be compared to “drawing with acid,” involving steps like masking, etching, and cleaning the metal to reveal the final design. For DIY projects, non-toxic alternatives like vinegar-based solutions offer a safer way to experiment with etching at home.

By understanding the basics of horn mesh etching, hobbyists, students, and industry professionals can appreciate the precision and versatility this method offers. For more information on etching solutions and materials, check out resources from companies like Metal Etching Company, which specialize in industrial etching processes.