Why Nano-Level Etching is a Game Changer

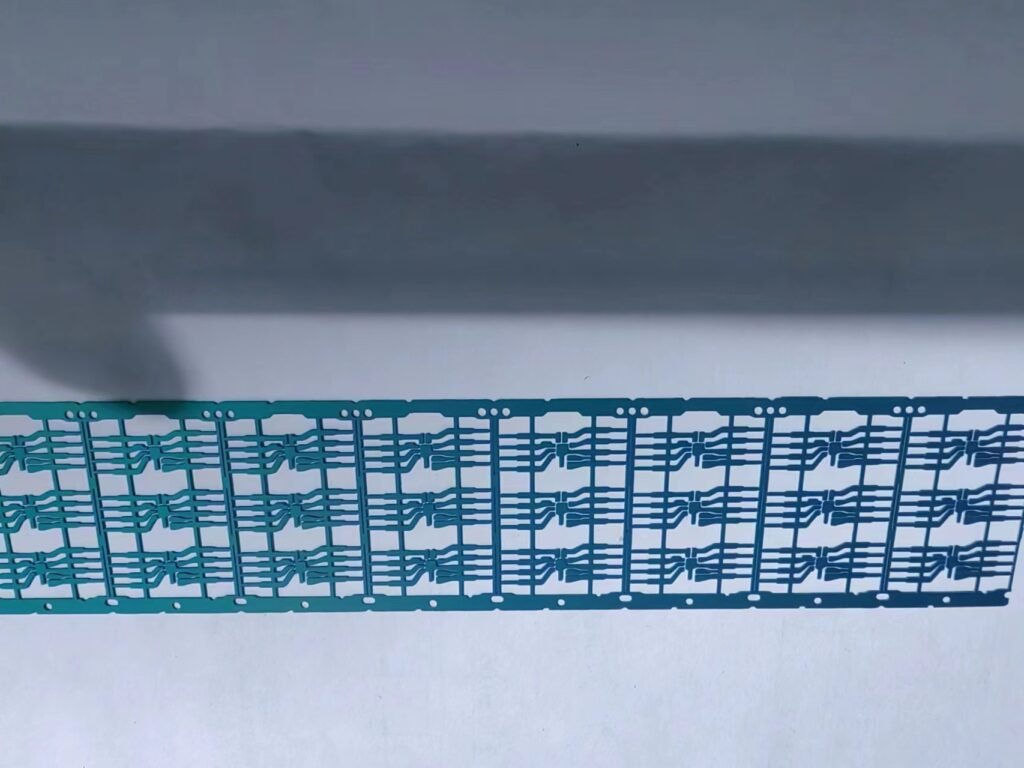

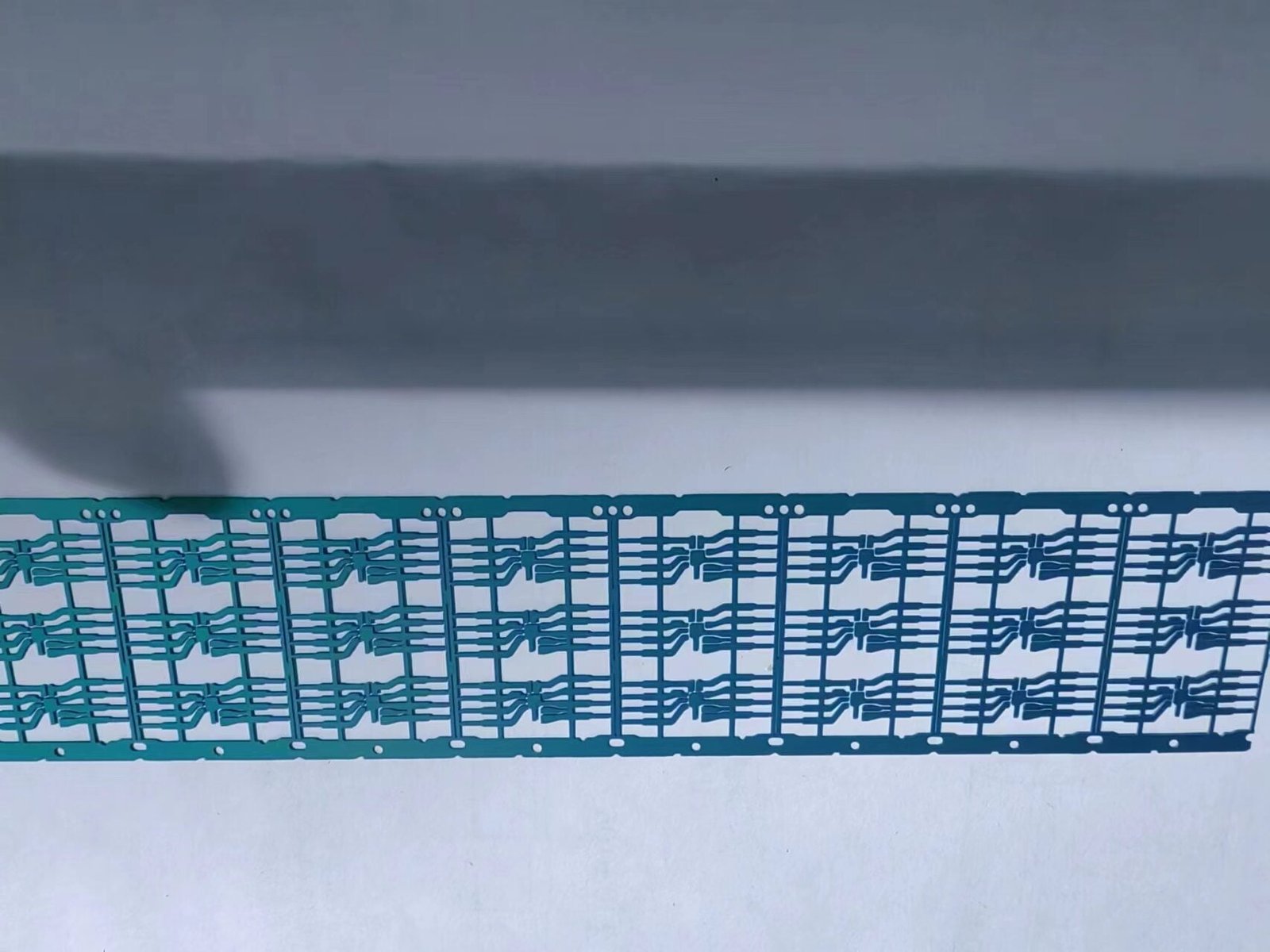

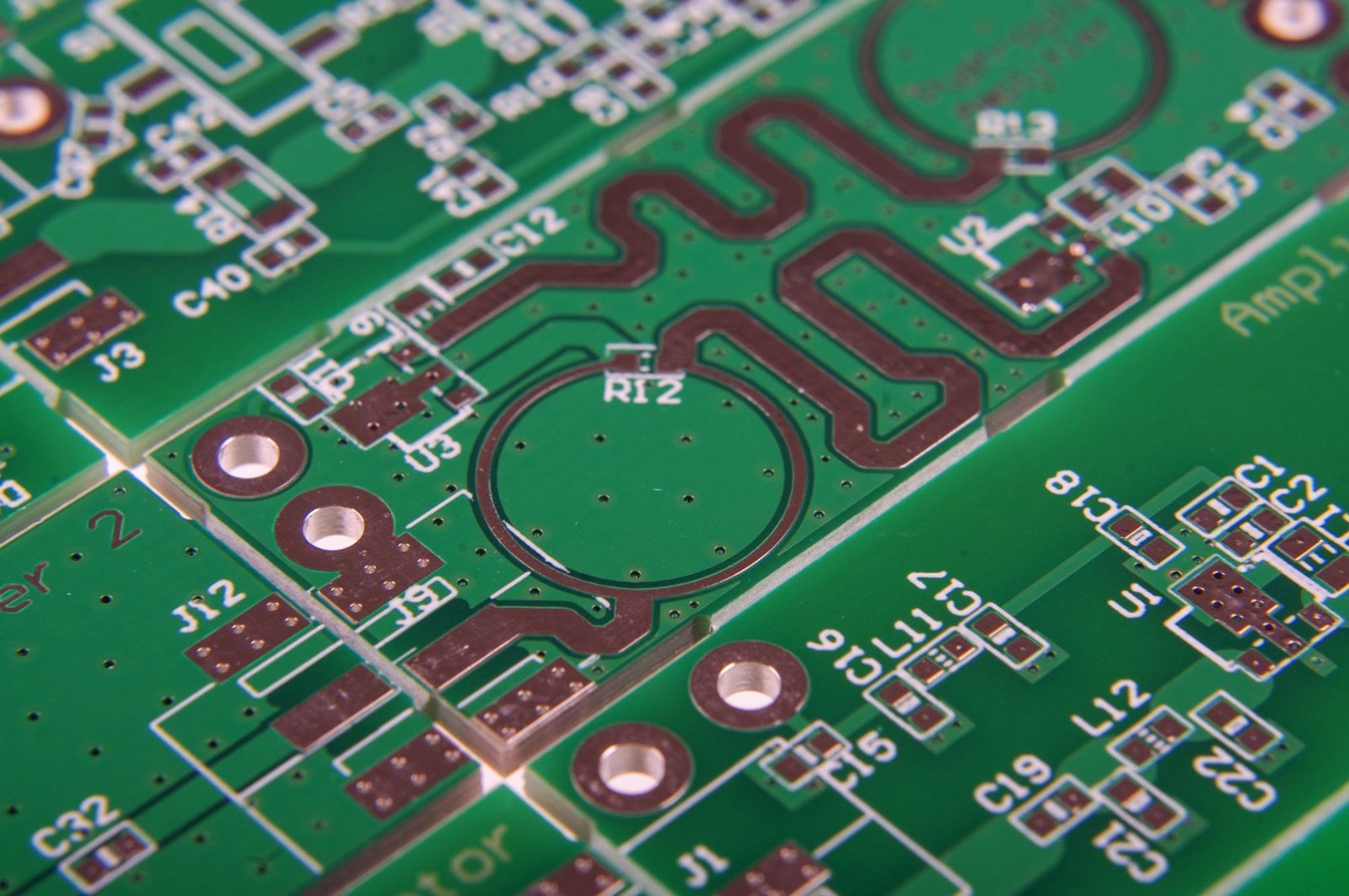

As electronic devices shrink in size while increasing in complexity, lead frame technology must evolve. The demand for ultra-precise, high-performance lead frames is pushing traditional etching methods to their limits. Nano-level etching, with its ability to achieve sub-micron accuracy (<1μm), is now at the forefront of next-generation semiconductor packaging.

This article explores the latest advancements in etching techniques, materials, and Industry 4.0-driven innovations that are redefining lead frame manufacturing.

Pushing the Limits of Precision

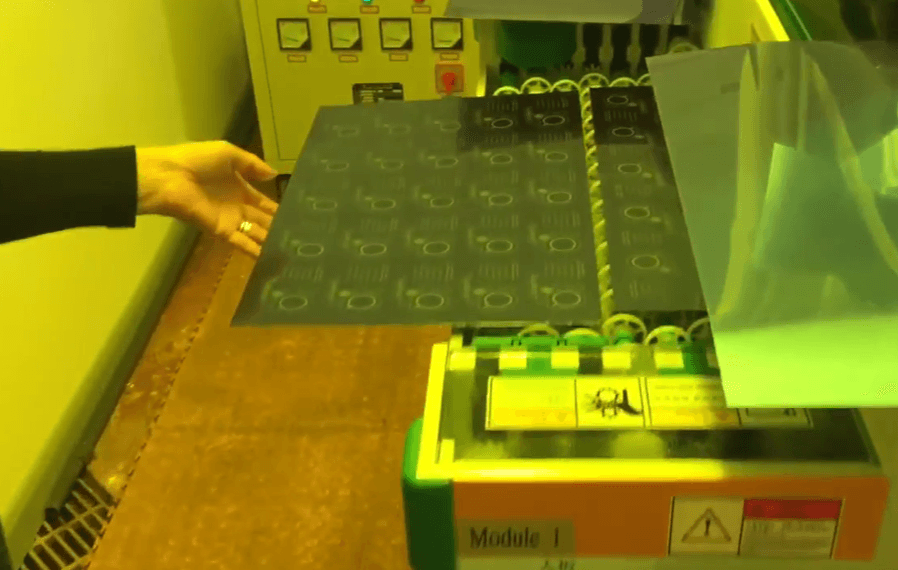

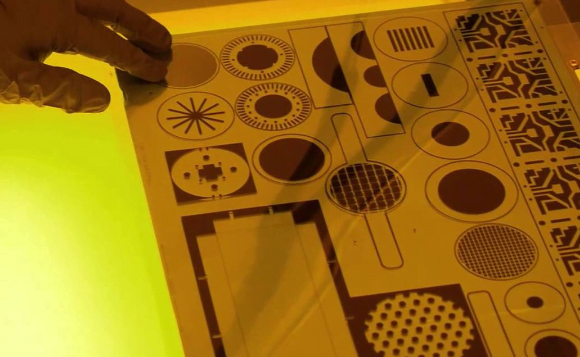

1. Laser-Assisted Etching: Enhancing Accuracy Beyond Traditional Methods

Traditional photochemical etching offers high precision, but combining laser-assisted techniques can further reduce overlay errors to <1μm.

| Etching Method | Accuracy | Key Advantages |

|---|---|---|

| Conventional Chemical Etching | ±5μm | Cost-effective, scalable |

| Photo-Chemical Etching with Multi-Layer Alignment | ±2μm | High resolution, suitable for fine-pitch designs |

| Laser-Assisted Chemical Etching | <1μm | Extreme precision, minimizes undercutting |

🔹 Case Study: Companies like Mitsubishi Electric have pioneered hybrid laser-assisted etching for ultra-fine interconnects, enhancing signal integrity in high-speed electronics (source).

2. Multi-Layer Alignment: Tackling Complex Lead Frame Structures

Multi-layered lead frames, crucial for 3D packaging and high-frequency RF applications, require perfect alignment to prevent signal loss or electrical interference.

✔ Solution: New optical alignment systems now ensure multi-layer etching errors stay below 1μm, a 10x improvement over traditional methods.

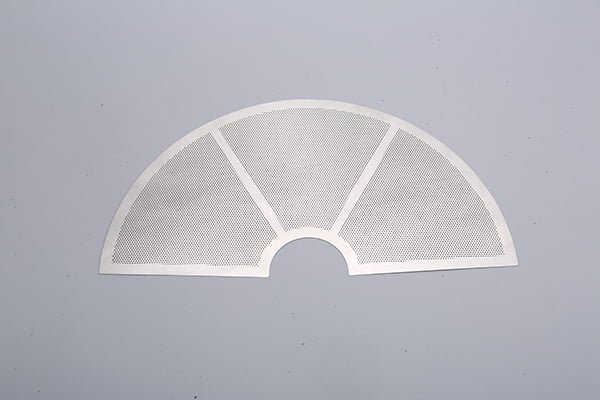

The Rise of Ultra-Thin Clad Metals

With the rise of 5G, IoT, and automotive radar, lead frames need to handle higher frequencies and harsher environments. This has led to the adoption of ultra-thin clad metals, combining the best properties of multiple materials.

| Material | Composition | Application |

|---|---|---|

| Cu/Fe/Ni Composite | Copper core for conductivity, iron for rigidity, nickel for corrosion resistance | 5G base stations, radar modules |

| BeCu Alloy | Beryllium copper for high elasticity and fatigue resistance | Wearables, medical sensors |

| Mo-Cu Alloy | Molybdenum for thermal management, copper for conductivity | High-power semiconductors, EV battery systems |

🔹 According to a recent study by Atotech, the use of Cu/Ni multilayered lead frames has led to 30% better thermal stability in automotive electronics (source).

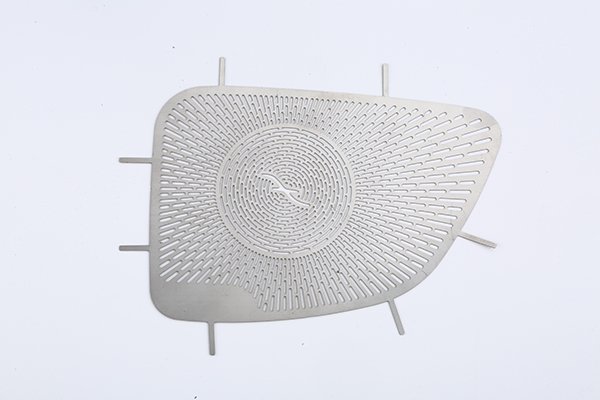

FEM for Stress Distribution Analysis

As lead frames become thinner and more intricate, mechanical stress during etching and stamping must be carefully managed.

✔ Finite Element Method (FEM) simulations help predict stress concentration points, minimizing deformation.

✔ Hybrid manufacturing models (etching + micro-stamping) are now optimized using AI-driven FEM software, allowing manufacturers to reduce failure rates by up to 25%.

📌 Example: Engineers at Infineon Technologies use FEM-driven etching simulations to optimize high-reliability lead frames for automotive ICs (source).

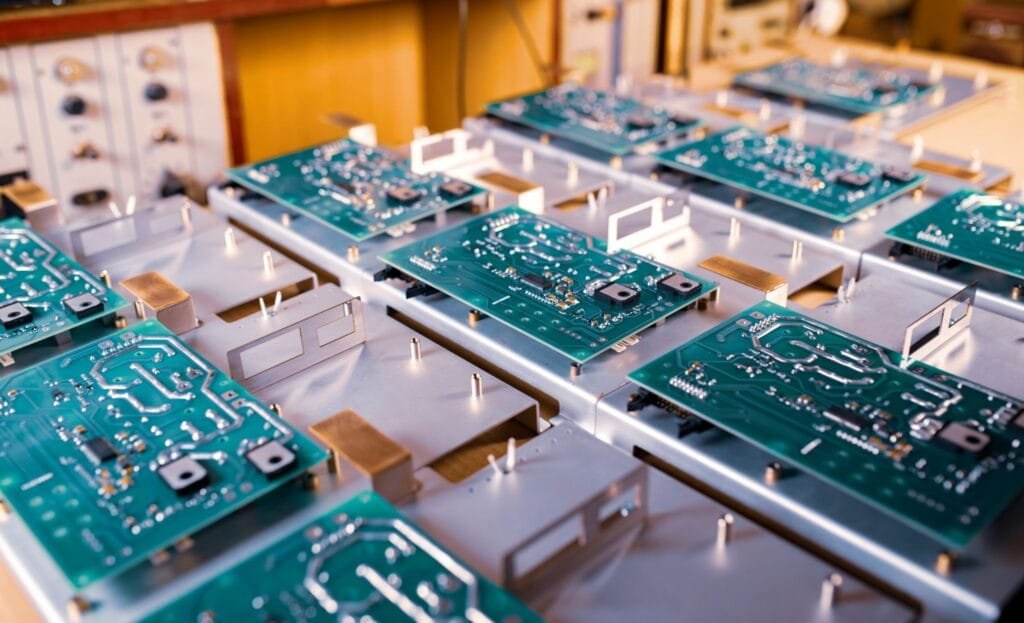

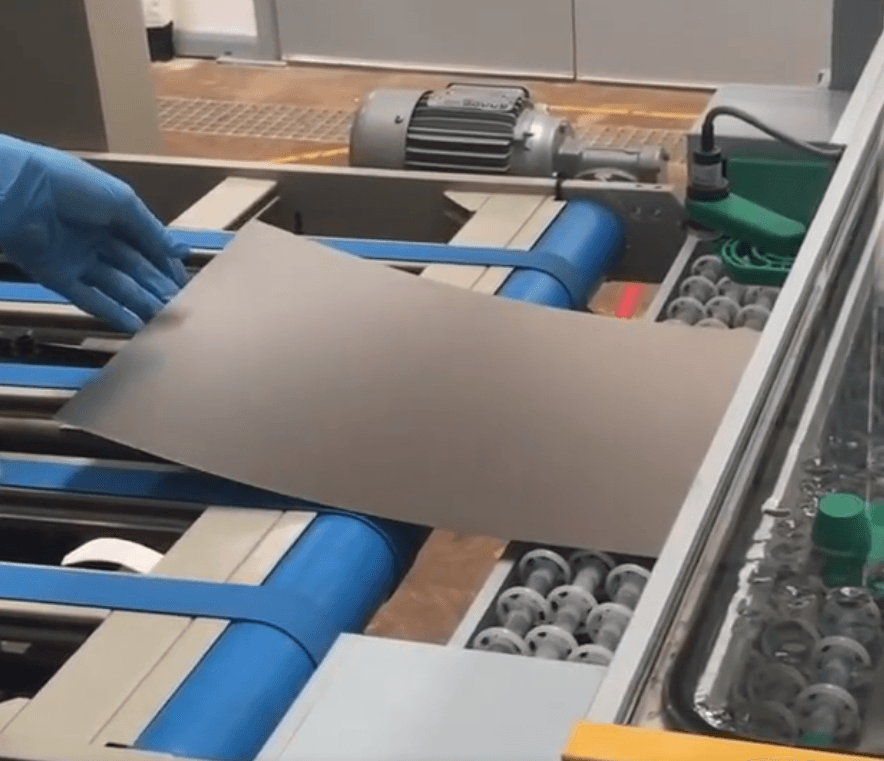

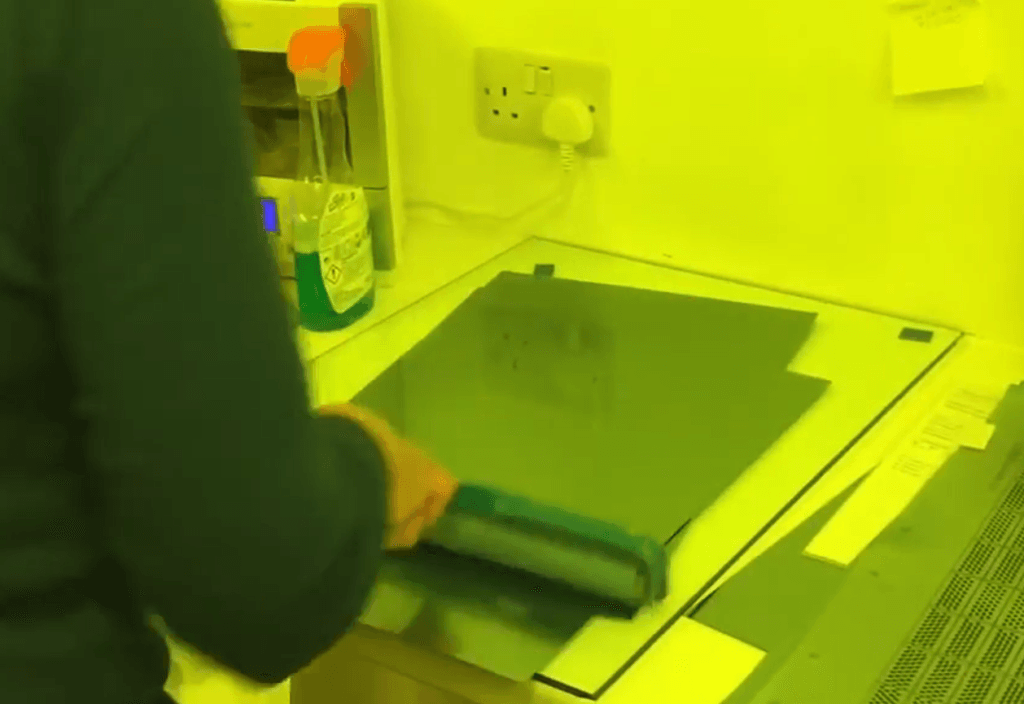

Smart Etching Tanks for Real-Time Monitoring

With Industry 4.0, etching processes are becoming smarter and more efficient.

IoT-Enabled Etching Tanks: Key Innovations

✔ Real-time pH & ion concentration sensors – Ensure consistent etching quality.

✔ Automated chemical replenishment – Reduces waste and improves process control.

✔ AI-driven defect detection – Uses machine learning to spot inconsistencies before they cause defects.

🔹 Case Study: Texas Instruments has implemented IoT-enabled chemical etching in their lead frame production, resulting in 15% lower defect rates and 20% higher yield (source).

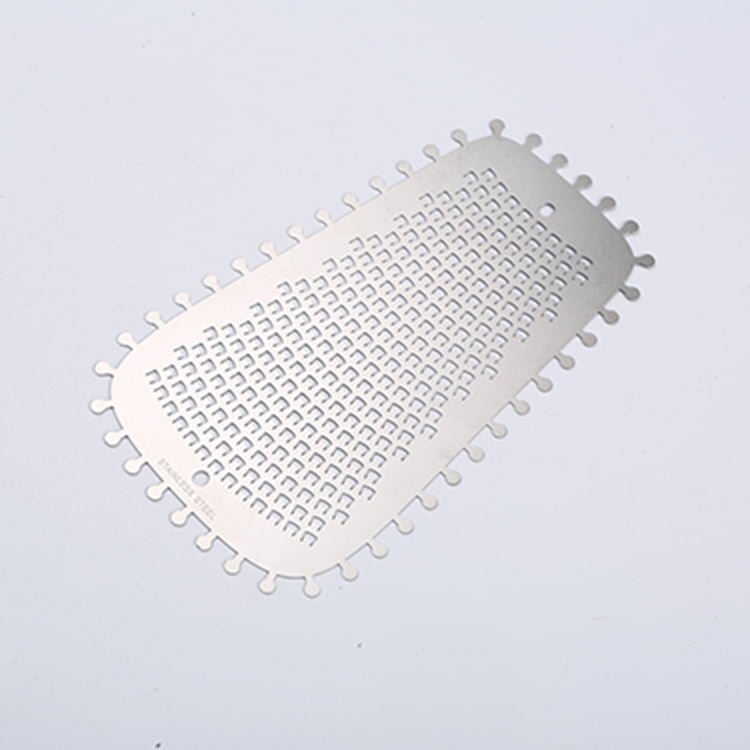

Anti-Corrosion Nanostructured Surfaces

A recent patent, US20230174521A1, details nanostructured coatings designed to improve the corrosion resistance of etched metal surfaces.

✔ Why it matters: Lead frames are exposed to harsh environments (moisture, oxidation, heat).

✔ Solution: Nano-coatings significantly improve durability, reducing corrosion-related failures by over 50%.

🔹 Patent Reference: US20230174521A1 – Anti-Corrosion Nanostructured Surfaces.

The Future of Nano-Level Etching in Lead Frames

The move toward nano-precision etching is breaking technological barriers, enabling smaller, faster, and more reliable lead frames for the next generation of electronics.

✔ Laser-assisted techniques & multi-layer alignment improve precision to sub-micron levels.

✔ Advanced clad metals enhance thermal & electrical performance for 5G and automotive applications.

✔ Smart, AI-driven etching systems drive efficiency and reduce defects.

✔ Patented nanostructured coatings ensure longer-lasting, corrosion-resistant lead frames.

🚀 With these innovations, the future of lead frame manufacturing is heading toward unparalleled precision and efficiency—powering the next wave of cutting-edge electronics.