Wet Processing Equipment for All Chemical Acid Etching Purposes

Selling Price:

$4000.00/m

View or download our Photochemical Metal Etching White Paper How-to Guide

Table of Contents

- Wet Processing Equipment – wet chemical acid etching machine

- Chemical Acid Etching Machine Equipment Parameters

- More Small Chemical Etching Machines

- Popular Wet Processing Combination Equipment

- Metals that can be processed by wet acid etching machine

- Wet Processing Equipment

- Our metal etching equipment processing workshop

- Features that can be added to a wet etching machine:

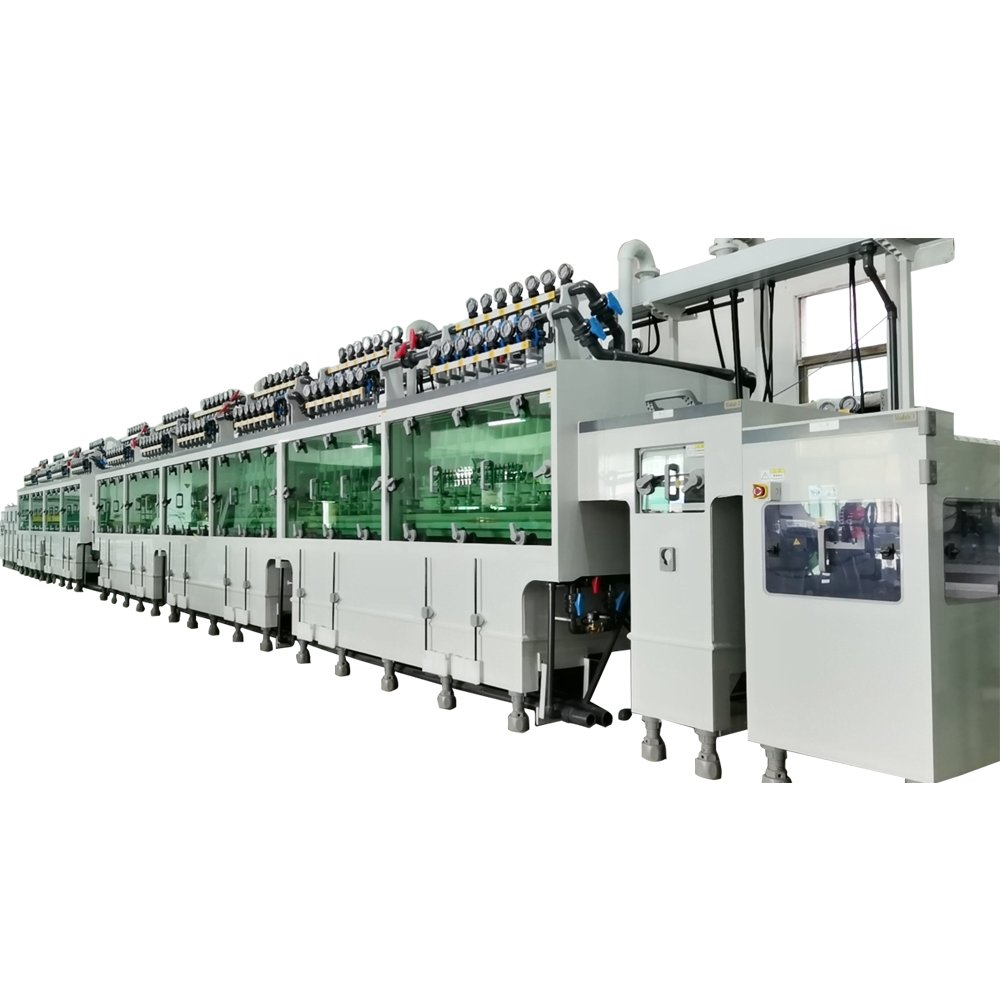

Wet Processing Equipment – wet chemical acid etching machine

The Chemical acid etching machine is used to spray chemical solution to a copper-clad laminator, aluminum substrate, or stainless steel plate, the exposed copper, aluminum, and stainless steel are etched away, retaining the pattern or circuit covered by the corrosion-proof film, so as to achieve the purpose of making pattern or circuit.

Customized chemical acid etching machine will be reasonably matched with your production line according to your production capacity.

Comparison Table

| Name | Characteristics | Main Process | Key Components |

|---|---|---|---|

| Chemical Etching machine | General purpose for various applications | Photoresist and etching | Photoresist unit, etching bath |

| Photo Etching machine | Focus on photographic techniques | Light exposure and development | Photoresist coater, UV exposure unit |

| Chemical Milling machine | Larger-scale, deeper cuts | Material removal for components | Larger etching tanks, waste management |

| Wet Etching machine | Uses liquid etchants | Submersion in etchants | Temperature control, rinsing equipment |

| Chemical Engraving machine | Broader term, can include engraving | Deep material removal | Laser unit, rinsing apparatus |

| Acid Etching machine | Specifically uses acids | Acid application | Acid handling system, safety equipment |

Precision: The etching precision of our machine is 0.0028mm, which allows us to manufacture micro-sized components with high accuracy.

Speed: The etching speed of our machine is determined by the qualityand temperatureof the etching solution used. Typically, higher temperaturesresult in faster etching.

Yield: Our machine achieves a high yield rate of 99.9% due to its high precision and controllable etching speed, which greatly improves manufacturing efficiency and reduces costs.

Manpower: Only two employees are needed to operate and maintain each machine, which reduces labor costs and increases production efficiency.

Chemical Acid Etching Machine Equipment Parameters

| birthplace | China |

| Guangdong | |

| brand | Dragon Etching |

| core inter-layers | 2 mil(where 1 mil is equal to 0.001 inches.) |

| PCB construction where | 250 mil |

| working width | 500/600/700/800MM customized |

| high | 900-1100mm customized |

| Thin Material Transport for PCB | 1m-100m depends on output |

| Voltage | 380V/415V/440V customized |

| Material | Polypropylene 12/15/ 20MM |

| Specificities | Flexible reel-to-reel Kapton,Rigid FR4,1~100m,2 mil material can be transported no problem(OEM) |

| heating type | SST316 titanium heater |

| Modular metal | SST316 titanium material |

| apply to | high precision etching (Wet Processing for PCB) |

| Common Processes | Etcher (Stand Alone)DES (Develop – Etch – Strip)SES (Strip – Etch – Strip)Custom Size (1 to as many chambers as you want) |

| Common Chemicals Etchant | Alkaline Etchant Cupric Chloride Etchant Ferric chloride Etchant Hydrofluoric Acid (HF)Micro etch |

| After Warranty Service | Video technical support, online support, spare parts |

Wet Knife mold etching machine

WET Knife mold etching machine for etching knives. Have the ability to professionally customize knives.

This etching machine is an all-in-one small knife and mold etching machine. It is easy to install and can be used after powering on.

Selling Price:

$8,000.00

More Small Chemical Etching Machines

If you are worried about your budget and you want to do simple chemical etching work and have limited production capacity, then we also have low-priced small chemical etching machines that can do work such as: metal nameplates, metal cards, and other small batches of metal products.

The starting prices for these devices are: $5,600.

As the number of features increases and the length of the equipment increases, the price also increases.

This document covers 6 small etching machine that will meet the needs of any low-volume etching facility.

Popular Wet Processing Combination Equipment

(DES) Develop – Etching – Stripping

DES noun explanation

(D) Developing

In photofabrication, developing is the post-exposure process.

Dissolve and remove the photoresist other than those required and form a pattern image of the photoresist.

There is a “soaking method” of immersion in the developer and a “spray method” of spraying, and there is a common use of spray methods in terms of supply efficiency of the developer.

Immediately after the development, a set of heating treatments called post-baking are carried out.

The post-baking box hardens the photoresist, which results in resistance to etching fluid in the next process and improves adherence to substrates.

(E) Etching

Etching is a post-developing process.

While continuously transporting using etchants suitable for metal materials (products), a large amount of etching is performed uniformly by the spray method.

As the management of the etchant is important, an etchant autoanalyzer is installed as a supplementary facility, and various chemicals are automatically supplied based on the feedback of each component analysis to maintain a constant etching rate.

(S) Stripping

Stripping is the post-etching process.

After etching, dissolve the unnecessary photoresist film.

Depending on the type of photo registry, sodium hydroxide heated around 40 to 80℃ or 100℃ is commonly used.

In the case of special resist, mixed solvents such as xylene, alcohols, and ketones may be used.

If the product cannot be stripped by immersion, physical force such as a brush or spray is applied to the product. Immediately after stripping, De-ionized water cleaning, drying, and rust prevention are performed as a set.

DES Line’s Advantages

By installing 3 processes on one device…

- the unit’s area becomes smaller.

- Since there is only one inlet (LD) and outlet (ULD), it can be operated by a minimum number of people.

- It’s cheaper than purchasing three separate machine

DES Line’s disadvantages

By installing 3 processes on one device…

- The tact time of the device is rate-determining in the slowest process.

- When a product defect occurs, it is difficult to determine which process is the cause.

- It is not suitable for various kinds of products whose processing conditions change significantly.

- It is not suitable for research and development purposes that assess and select types of photoresist or film thickness.

SES Etching Maching

The Dragon Etching SES lines with innovative filter systems clean the entire stripping solution before it is returned to the tank container. Depending on the resist type, a cyclone filter system, a drum filter system, or a combination of both is used. The stripping process adjusts to the type of resist and then removes the remaining photoresist on the circuits.

Metals that can be processed by wet acid etching machine

- Wet Chemical Etching Stainless Steel

- Wet Chemical Etching Invar

- Wet Chemical Etching Germanium

- Wet Chemical Etching Gallium Nitride (GaN)

- Wet Chemical Etching Indium

- Wet Chemical Etching Cobalt

- Wet Chemical Etching Tungsten

- Wet Chemical Etching Aluminum

- Wet Chemical Etching Kovar

- Wet Chemical Etching Copper

- Wet Chemical Etching Steel

- Wet Chemical Etching Nickel

- Wet Chemical Etching Platinum

- Wet Chemical Etching Silver

- Wet Chemical Etching Rhodium

- Wet Chemical Etching Hafnium

- Wet Chemical Etching Vanadium

- Wet Chemical Etching Zirconium

- Wet Chemical Etching Titanium

- Wet Chemical Etching Niobium

- Wet Chemical Etching Tantalum

- Wet Chemical Etching Molybdenum

- Wet Chemical Etching Brass

- Wet Chemical Etching Rhenium

Wet Processing Equipment

Wet Chemical Etching Machine

Customize your Equipment

- Check out our Wet Processing Equipment.

- Select the product you are interested in, to find all your possible options.

- Then contact your sales rep to get moving on your new piece of equipment.

- If no products catch your eye please contact us. We have done many 100% customized machines!

Our metal etching equipment processing workshop

Features that can be added to a wet etching machine:

- Acid Controller – Popular for cupric chloride etchant

- Drying – Ensures products come out of the line dry.

- Inline Filtration – Results in fewer clogged nozzles and particles in solution.

- Ion Exchange – Saves water in rinse stations.

- pH Controller – Popular option for Alkaline etching. Standard on developing and resisting stripping lines.

- Ventilation Demister – Aids in condensation and recovery of evaporated process chemistry.

- Thin Material Transport – Transport very thin and flexible materials without the use of leaders.

- Drip Pan – Catches chemistry drops or spills

- Chiller Cooling System – Increased cooling capabilities.

- ORP Controller – Popular option for Cupric and Ferric etchers. Comes with a regeneration system.

- Specific Gravity Controller (IX) with Visual Baume – Prevents etchant Baume from getting too low or high.

- Recipe-Driven Operation – Eliminates product variation due to improper machine set-up.

- Data Collection and Archiving – Gives real-time and historical feedback analysis.

Typically used for PCB outer layer etching

The options do not stop there. WET ETCHING wet processing machines are modular — allowing you to configure your machine in any order you desire.