Discover the key differences between metal cutting and chemical etching for 1mm 304 stainless steel. Learn how each method impacts precision, cost, and efficiency, and find out which technique is best suited for your metal fabrication needs.

Table of Contents

Metal Cutting vs. Chemical Etching for 1mm 304 Stainless Steel: A User’s Perspective

1. Introduction

Metal fabrication plays a crucial role in various industries, involving techniques like metal cutting and chemical etching. Both are widely used for processing metals, but they serve different purposes depending on precision, material thickness, and production volume. This article aims to explore the differences between these methods when working with 1mm thick 304 stainless steel, helping you choose the right technique for your needs.

2. Metal Etching – Wet Chemical Etching

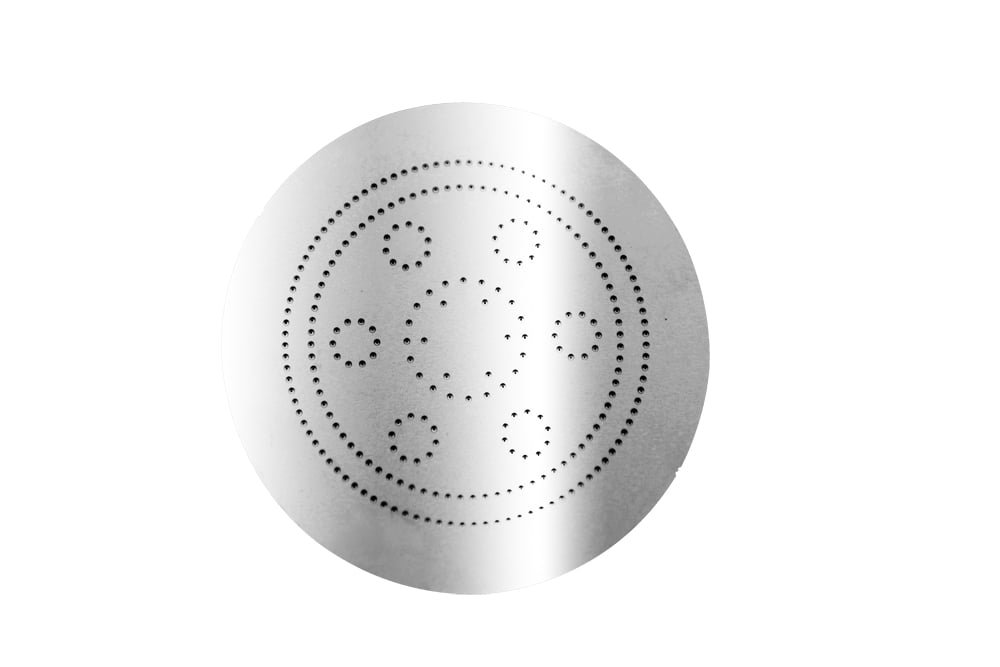

Metal etching, particularly wet chemical etching, is a process that uses chemical solutions to remove material from the metal surface. Common applications include PCB manufacturing, precision electronics, and intricate metal designs. The process involves using a mask to protect areas of the metal, while chemicals dissolve the exposed parts.

Advantages:

- High precision: Ideal for intricate designs and fine details.

- Maintains material properties: No heat is involved, so there’s no distortion or weakening of the material.

- Complex shapes: Etching excels at handling complex internal and external contours.

3. Metal Cutting – CNC, Laser, Waterjet Cutting

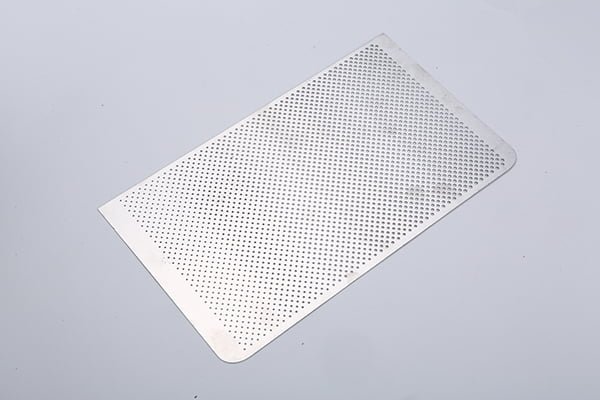

Various cutting methods are used in metal fabrication, such as laser cutting, CNC machining, and waterjet cutting. Laser cutting, especially with a 1500W machine, is popular for processing stainless steel. It’s used for large-scale production and structural components, offering fast operation and the ability to cut thicker materials.

Advantages:

- Speed: Laser cutting is fast and efficient, especially for thicker materials.

- Versatility: Suitable for various thicknesses and large-scale production.

- Mechanical impact: Mechanical stress on the material is minimal, but thermal effects can sometimes cause imperfections on thin sheets.

4. Technical Comparison

Let’s compare the two methods for processing 1mm 304 stainless steel:

- Precision:

- Wet chemical etching offers extreme precision, with tolerances as tight as ±0.003mm. It’s ideal for fine details on thin sheets.

- Laser cutting, while also precise, has a tolerance of around ±0.02mm on thin material, and the heat can cause warping or burrs on the edges.

- Material Suitability:

- Chemical etching works best on thin and sensitive materials like 1mm stainless steel.

- Cutting methods like laser and waterjet excel on thicker materials but may struggle with very thin sheets, where heat distortion or rough edges can be issues.

- Production Cost:

- Etching tends to have higher upfront costs for equipment and chemical handling but lower material waste, especially for fine details.

- Cutting, especially laser cutting, has higher equipment costs but lower per-unit costs for large-scale production.

- Flexibility:

- Etching can handle highly complex designs with internal and external contours, while laser cutting is better suited for simple shapes and quick production.

5. Choosing the Right Metal Processing Method

Choosing between metal etching and metal cutting depends on your specific needs:

- For precision work: If you need to process thin sheets (like 1mm 304 stainless steel) with intricate, fine details, and high precision, etching is the superior option. Its ability to handle complex shapes and maintain material integrity makes it ideal for applications such as electronics or decorative pieces.

- For bulk production: If precision is less important and speed is the priority, particularly for larger production runs, laser cutting is a better fit. Its fast processing times and ability to cut through thicker materials make it suitable for projects like structural components or high-volume manufacturing.

In conclusion, neither metal etching nor metal cutting is universally superior. The choice depends on the application and production requirements.

View or download our Photochemical Metal Etching White Paper How-to Guide

From a Metal Fabrication Service Provider’s Perspective

For a metal fabrication service provider processing 1mm 304 stainless steel, the differences between chemical etching and cutting lie in precision, production costs, and equipment investment. Here’s how these two processes compare:

1. Precision and Complexity

- Metal Etching: For 1mm stainless steel, etching provides incredibly high precision, perfect for intricate designs like small holes, fine lines, and complex contours. Etching doesn’t apply physical force, so there’s no risk of deformation, which is critical for thin materials.

- Metal Cutting: While laser cutting offers good precision, handling fine interior and exterior contours may require additional post-processing. Thin materials like 1mm steel can warp or develop burrs under high heat, making etching the better option for detail work.

2. Edge Quality

- Metal Etching: Produces smooth, burr-free edges due to the gradual removal of material through chemical processes. There’s no need for additional polishing, which is ideal for thin, delicate materials.

- Metal Cutting: Laser cutting may result in slightly rough edges or heat-affected zones, requiring extra polishing, particularly on thinner metals.

3. Production Efficiency

- Metal Etching: While etching involves multiple steps like mask creation and chemical processing, it is highly efficient for large batches after initial setup. The precision makes it slower for small or one-off production runs.

- Metal Cutting: Laser cutting is fast and ideal for large-volume production. For simple shapes and faster turnarounds, it’s the preferred method.

4. Material Waste and Cost

- Metal Etching: Uses chemicals to remove material, which can lead to waste management costs. While initial setup for large-scale production can be slow, once in place, the cost per unit is low.

- Metal Cutting: Laser cutting involves minimal material waste, as it cuts with a narrow kerf. Although equipment costs are high, laser machines have relatively low operational costs in terms of electricity and maintenance.

5. Applicable Scenarios

- Metal Etching: Best suited for applications requiring precise, intricate designs, such as signage or electronics. For 1mm 304 stainless steel, etching offers a high level of detail and edge quality.

- Metal Cutting: Better for simple designs and high-volume production, where speed and efficiency are crucial. It works well for industrial components or enclosures.

Cost Breakdown: Equipment, Labor, and Utilities

- Machine Cost:

- Metal etching: $50,000 – $150,000 for an etching setup, including chemical handling equipment(Chemical etching machine, chemical cleaning machine, grinding machine, chemical solution stripping machine, etc.).

- Laser cutting: $100,000 – $300,000 for a mid-range laser cutting machine.

- Labor:

- Etching: Typically requires 2-3 operators, with labor costs of $9,600 – $14,400 per month.

- Laser cutting: Needs fewer operators (1-2), reducing labor costs to $3,200 – $6,400 per month.

- Space Requirements:

- Etching: 50-100 square meters for equipment and chemical storage, costing $500 – $1,000 per month.

- Laser cutting: 20-40 square meters, with a space cost of $200 – $400 per month.

- Utilities:

- Etching: Higher water and electricity consumption, with monthly costs of $560 – $1,090.

- Laser cutting: Primarily electricity costs of $240 – $360 per month, with no water usage.

- Environmental Costs:

- Etching: Chemical waste handling costs of $1,000 – $2,000 per month.

- Laser cutting: Minimal environmental costs, typically $100 – $300 for air filtration systems.

Chemical Etching vs Metal Laser Cutting Cost Table

| Cost Factor | Metal Etching | Laser Cutting |

|---|---|---|

| Equipment Cost | $50,000 – $150,000 | $100,000 – $300,000 |

| Personnel (monthly) | $9,600 – $14,400 | $3,200 – $6,400 |

| Space (monthly) | $500 – $1,000 | $200 – $400 |

| Utilities (monthly) | Water: $60 – $90, Electricity: $500 – $1,000 | Electricity: $240 – $360 |

| Waste/Environmental | $1,000 – $2,000 | $100 – $300 |

| Maintenance (monthly) | $1,000 – $2,000 | $500 – $1,000 |

Conclusion

For thin metal processing, particularly with detailed designs, metal etching remains a strong choice due to its high precision and smooth finish. However, for faster, large-scale production, especially where detail isn’t as critical, laser cutting offers greater efficiency and cost-effectiveness. Each method has its strengths, and the choice depends on the specific requirements of the project.

If you have metal wet etching needs, please feel free to contact us.

FAQs

[FAQS]