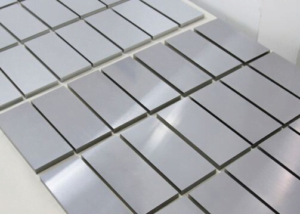

Glossy nickel, Matte nickel, Black nickel, High-hardness nickel

The electroforming process utilizes electrochemical reactions, similar to electroplating.

It reproduces the shape of the master shape by electrodepositing metallic ions onto the surface of the master and excels in dimensional precision and transferability.

WETETCH’s electroforming is “Nickel electroforming” combined with photolithography technology.

It achieves a high level of dimensional precision which is not possible by the photoetching process.

It uses straight processing for high-definition patterns and overhang processing for minuscule holes.