Tungsten, known for its remarkable strength and high melting point, is a versatile metal widely used in various industries.

Our Packages

- From 1000pcs

- Samples from 100pcs

- Approx. 30 days (may vary depending on the difficulty of the drawing)

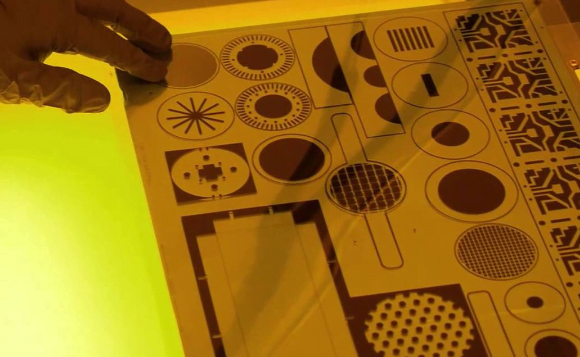

View our tungsten etching production facility

Tungsten Characteristics:

Tungsten, a refractory metal, possesses exceptional properties that make it ideal for various applications:

- High Melting Point: Tungsten’s melting point of 3422°C (6192°F) makes it suitable for high-temperature applications, such as aerospace components and heating elements.

- Superior Strength: Tungsten is renowned for its high tensile strength, enabling it to withstand extreme conditions and heavy loads.

- Excellent Electrical Conductivity: Tungsten has one of the highest electrical conductivities among metals, making it invaluable in the electronics and electrical industries.

- Density: With a density close to that of gold, tungsten imparts a satisfying heft to precision components.

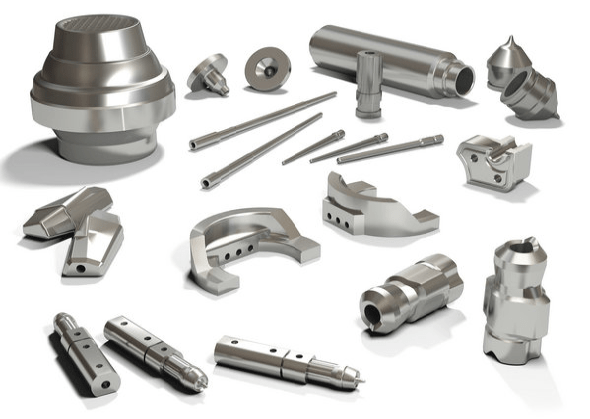

Etching Tungsten probe

WET is a professional manufacturer of high-quality tungsten probes for batch customization. In the realm of precision engineering, where every micron matters, fine tungsten probes emerge as indispensable tools driving innovation and discovery. As manufacturers strive to meet the exacting demands of various industries, the role of fine tungsten probe batch customization becomes paramount.

| Parameter | Description | Typical Range | Application Areas |

|---|---|---|---|

| Probe Tip Diameter | Diameter of the probe tip | 0.001 – 0.020 inches | Precision Instrument Probes, Microelectronics |

| Tip Radius | Radius of the probe tip | 0.0005 – 0.005 inches | Semiconductor Testing, Nanotechnology |

| Taper Length | Length of the taper portion | 0.010 – 0.200 inches | Biomedical Research, DNA Sequencing |

| Overall Length | Total length of the tungsten probe | 0.050 – 1.000 inches | Electronics Testing, Material Analysis |

| Shaft Diameter | Diameter of the probe shaft | 0.005 – 0.050 inches | MEMS (Microelectromechanical Systems) |

| Coating | Optional coating for enhanced properties | Various options available | Optoelectronics, Optical Fiber Testing |

Etching Hook-type 99.5% tungsten needle

These miniature precision microtool tips are helpful for particle manipulation or sample prep. They are available as individual interchangeable tips.

Tungsten alloy with durable 0.001″ radius tip

Etching 90° Microhook 99.5% tungsten

These miniature precision microtool tips are helpful for particle manipulation or sample prep. They are available as individual interchangeable tips.

Etching 99.5% tungsten Microneedle – Straight

These miniature precision microtool tips are helpful for particle manipulation or sample prep. They are available as individual interchangeable tips.

Etching Tungsten [Etching process]:

Metal etching is a precise process used to selectively remove material from the surface of tungsten to create intricate designs and patterns. When etching tungsten, the choice of etchant is critical for optimal results:

Chemical etching of tungsten typically involves the use of a mixture of hydrofluoric acid (HF) and nitric acid (HNO3) as the etchant solution. This combination of acids is effective in etching tungsten because it can react with the metal to form soluble tungsten fluoride compounds. The specific ratio of HF to HNO3 and other process parameters may vary depending on the desired etching rate and surface finish.

It’s essential to exercise extreme caution when working with these acids, as they can be highly corrosive and pose significant safety risks. Proper safety equipment and procedures should be followed when handling and disposing of these chemicals, and the process should be conducted in a well-ventilated fume hood or under controlled conditions in a chemical etching facility.

Ferric chloride (FeCl3) is a common etchant used for a wide range of metals, but it is not effective for etching tungsten. The reason for this is related to the specific chemical properties and reactivity of tungsten.

Ferric chloride primarily works as an oxidizing agent and relies on the formation of metal chlorides to etch metals. However, tungsten is a highly refractory metal with a high melting point and exceptional resistance to oxidation and corrosion. Tungsten forms a stable oxide layer (tungsten oxide) on its surface when exposed to oxygen or oxidizing agents, and this oxide layer acts as a protective barrier, preventing further reaction with the etchant.

Hydrofluoric acid (HF), on the other hand, is effective for etching tungsten because it can dissolve the tungsten oxide layer. HF is a strong acid that can react with metal oxides, including tungsten oxide, to form soluble fluoride complexes. This reaction removes the oxide layer and exposes the underlying tungsten for further etching.

Tungsten etching equipment

Wet Processing Equipment – Tungsten etching machine

The Tungsten etching machine is used to spray chemical solution to a copper-clad laminator, aluminum substrate, or stainless steel plate, the exposed copper, aluminum, and stainless steel are etched away, retaining the pattern or circuit covered by the corrosion-proof film, so as to achieve the purpose of making pattern or circuit.

This etching machine is an all-in-one small Tungsten etching machine that is easy to install and can be used immediately after powering on.

Photo Etching Tungsten:

Photo etching is a precise process used for intricate designs on tungsten:

- Material Film: Photomasks made of high-quality polymer films with excellent UV resistance are recommended for precise and detailed etching.

- Temperature Control: Maintain a stable and controlled temperature during the photoresist exposure and development process to ensure accurate pattern transfer.

Tungsten’s exceptional properties make it a valuable material for precision machining in various industries. Employing the right etchants, surface treatment methods, and electroforming techniques, alongside proper metal cleaning and photo etching, ensures optimal results without compromising tungsten’s integrity. Understanding these processes and precautions will enable manufacturers to produce high-quality tungsten products for specific applications, ranging from electronics to aerospace and beyond.

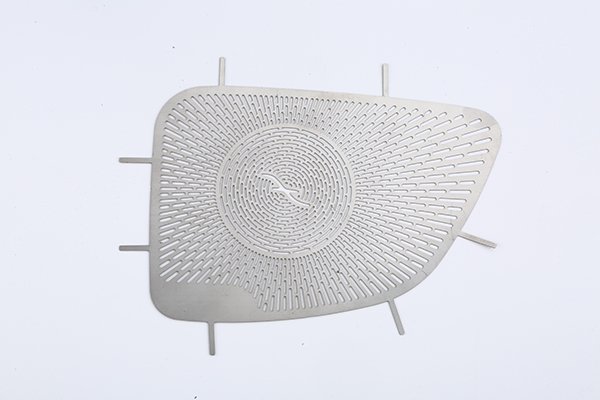

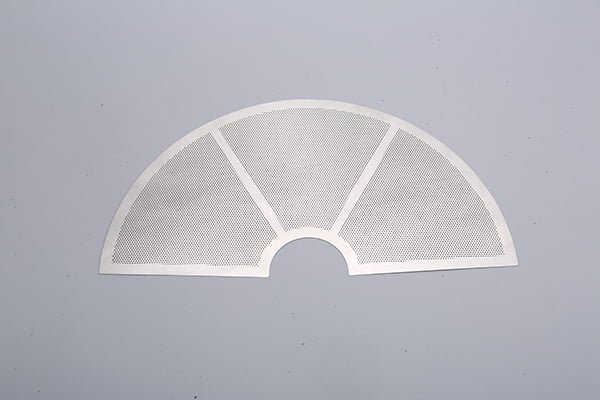

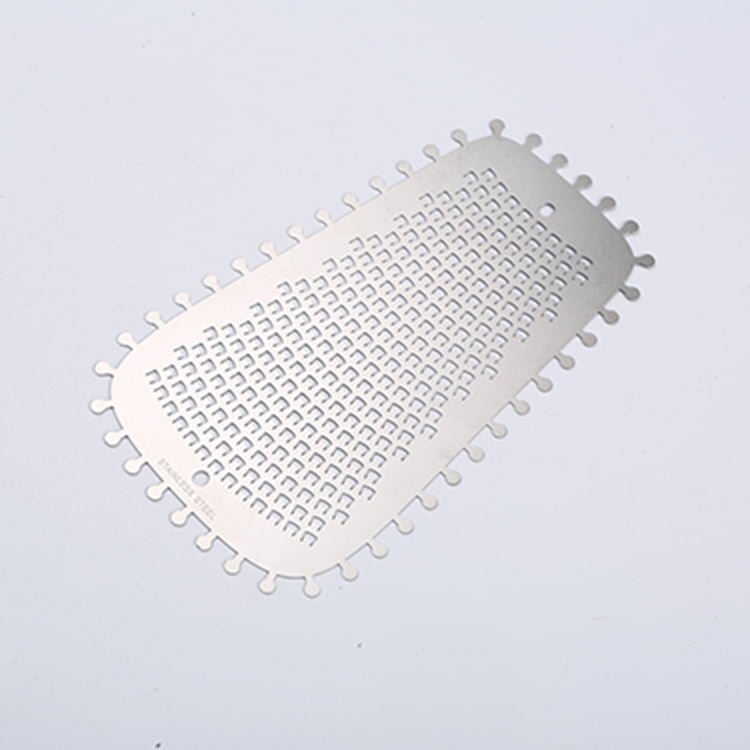

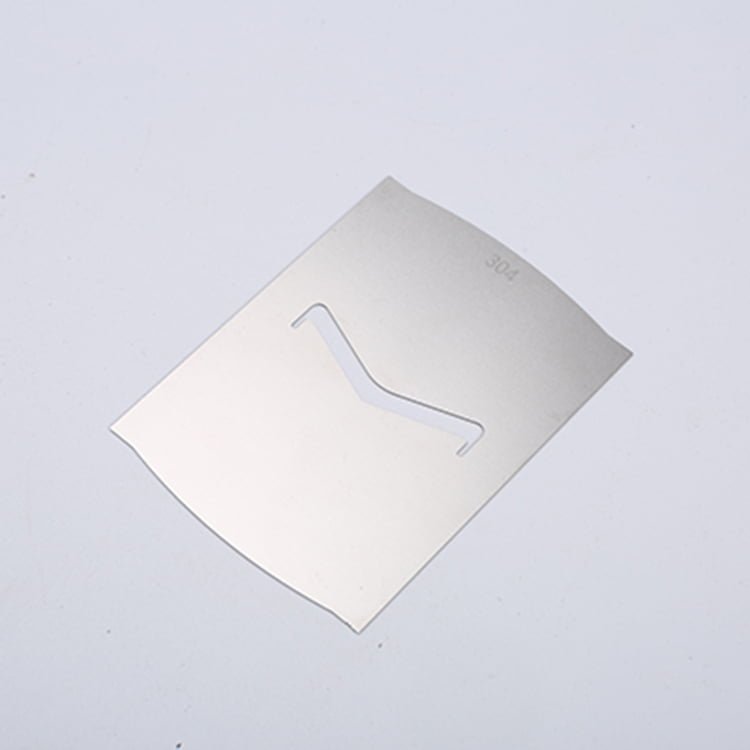

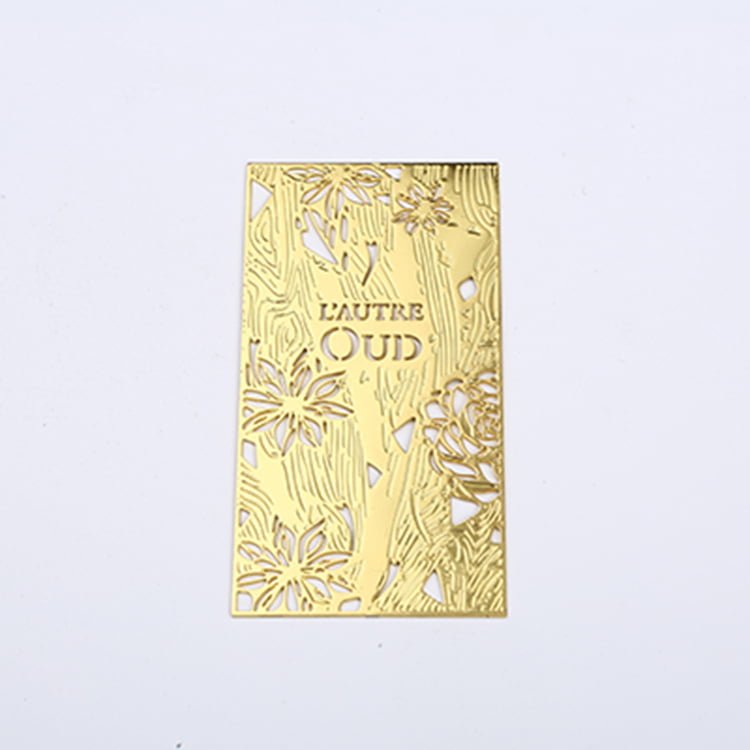

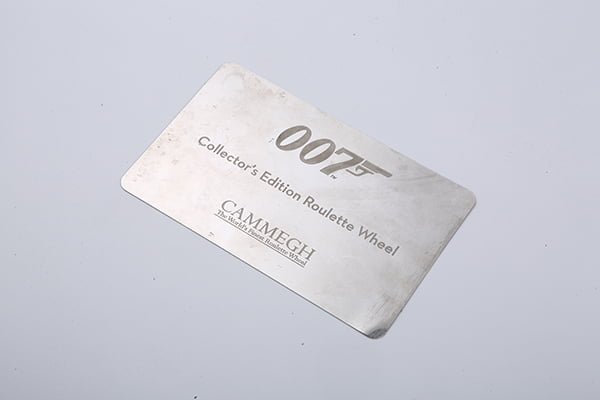

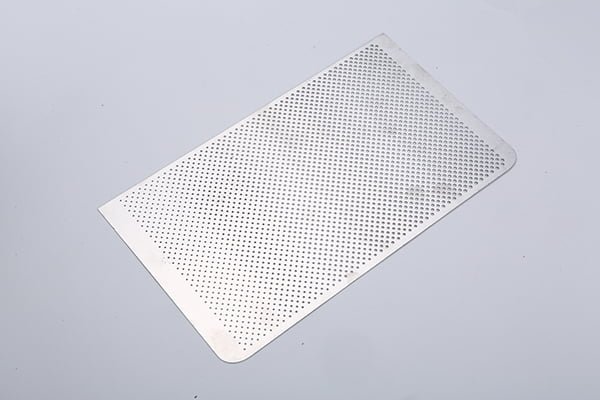

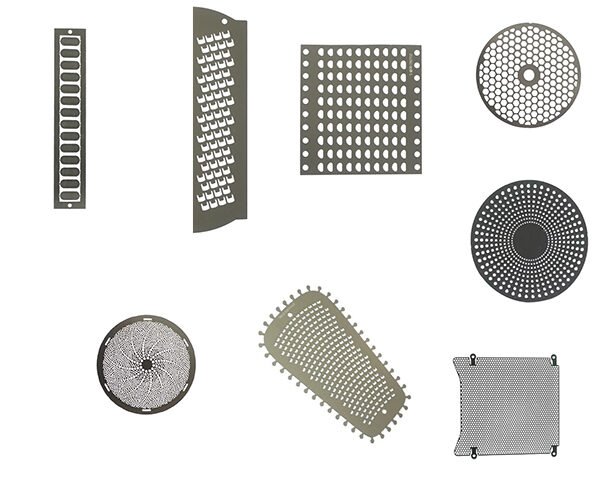

View our metal etching products

how to etch Tungsten?

Etching Tungsten Process Guidelines

| Metal Etching | Etchant | Etching Temperature (°C) | Etching Concentration (%) | Estimated Etching Depth (microns) | Etching Quality |

|---|---|---|---|---|---|

| Etching Tungsten | Potassium Hydroxide (KOH) | Room temperature | 20-30% KOH | 1-10 | High-quality (smooth) |

| Etching Tungsten | H2O2 and H2SO4 (Piranha solution) | Room temperature | 30% H2O2, 70% H2SO4 | 5-20 | High-quality (smooth) |

| Etching Tungsten | NH4OH and H2O2 | Room temperature | 30% NH4OH, 3% H2O2 | 2-15 | High-quality (smooth) |

The values provided are approximate and can vary depending on specific etching conditions, including exposure time and the condition of the tungsten surface. Always conduct test etches and adjust parameters as needed to achieve your desired results. Additionally, safety precautions should be followed when handling these chemicals, especially in the case of Piranha solution.

If you have metal wet etching Tungsten needs, please feel free to contact us.

FAQs

What metals can you use to customize my goods?

- Wet Etching Germanium

- Wet Etching Gallium Nitride (GaN)

- Wet Etching Indium

- Wet Etching Cobalt

- Wet Etching Tungsten

- Wet Etching Stainless Steel

- Wet Etching Aluminum

- Wet Etching Kovar

- Wet Etching Copper

- Wet Etching Steel

- Wet Etching Nickel

- Wet Etching Platinum

- Wet Etching Silver

- Wet Etching Rhodium

- Wet Etching Hafnium

- Wet Etching Vanadium

- Wet Etching Zirconium

- Wet Etching Titanium

- Wet Etching Niobium

- Wet Etching Tantalum

- Wet Etching Molybdenum

- Wet Etching Brass

- Wet Etching Rhenium

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.

Etching Tungsten Samples