Titanium, a versatile and lightweight metal, is widely used in various industries, including aerospace, medical devices, and automotive.

Our Packages

- From 1000pcs

- Samples from 100pcs

- Approx. 30 days (may vary depending on the difficulty of the drawing)

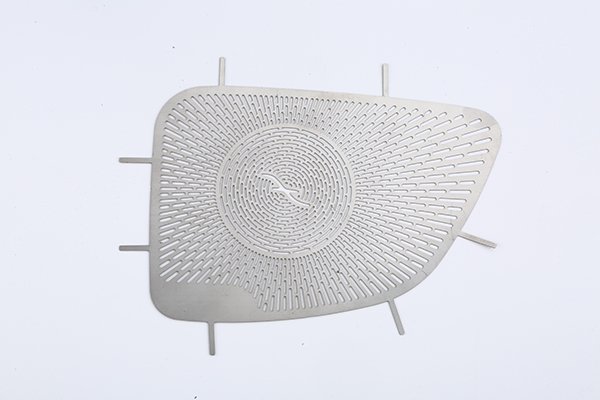

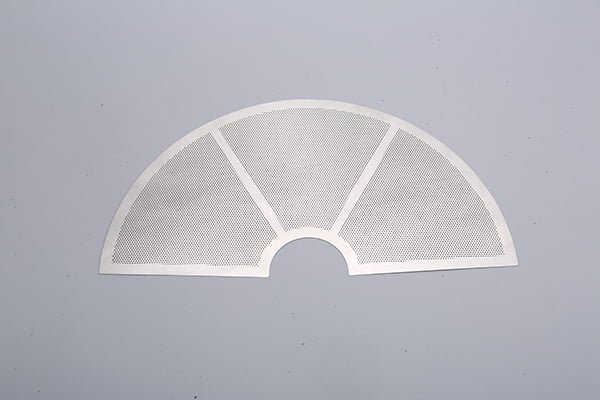

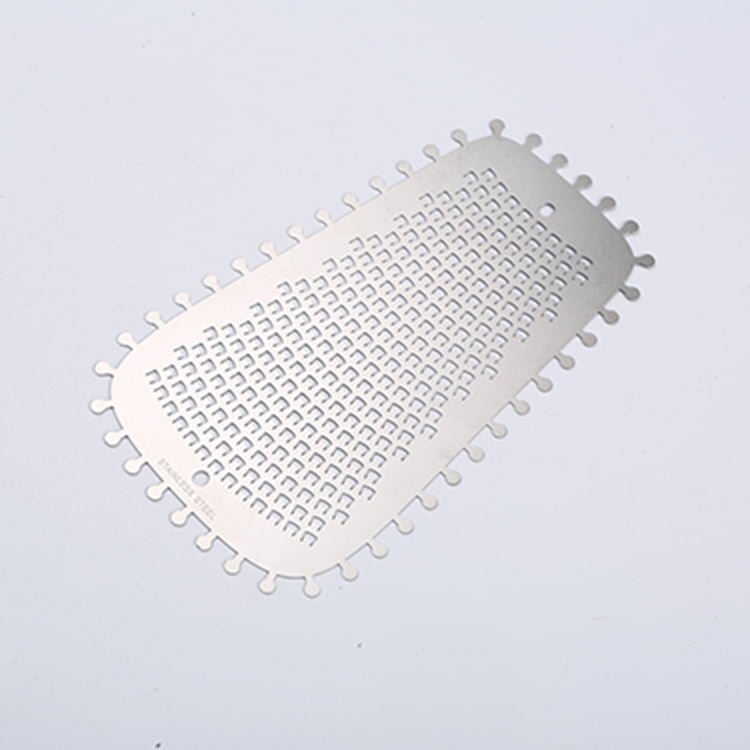

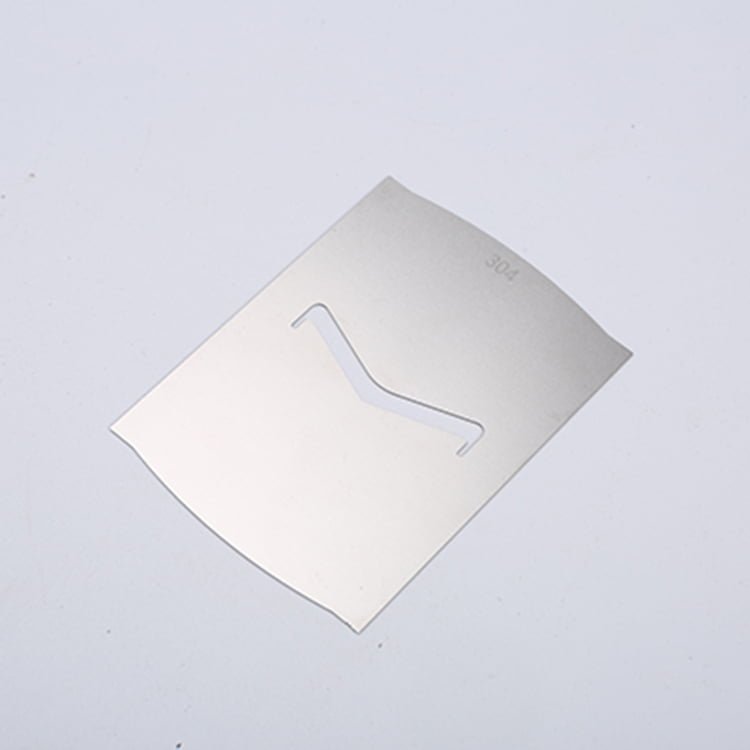

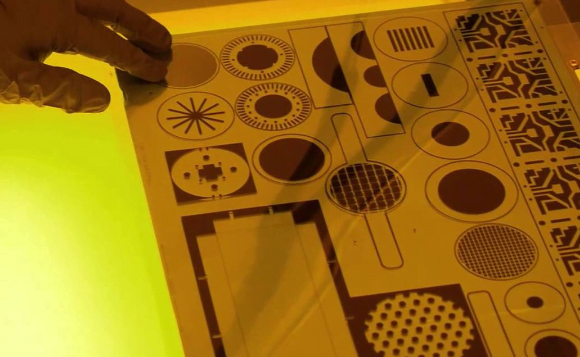

View our Titanium etching production facility

Types of Titanium and Alloys: Advantages and Disadvantages in Wet Processing

Titanium comes in various forms, and alloying it with other elements can enhance specific attributes. Let’s analyze the advantages and disadvantages of each alloy in wet processing:

- Pure Titanium: Advantages include excellent corrosion resistance and biocompatibility, making it suitable for medical implants. However, its high ductility can pose challenges during certain etching processes, leading to deformation.

- Titanium-Aluminum (Ti-Al): This alloy offers improved strength and elevated temperature performance. However, its hardness may require careful consideration during etching to avoid surface damage.

- Titanium-Nickel (Ti-Ni): The addition of Nickel enhances shape memory and superelasticity properties. While ideal for biomedical applications, the etching process must be precisely controlled to maintain material integrity.

Metal Etching Titanium

Metal etching in the wet processing process involves the use of metal etching machines. The choice of etchant, such as Hydrofluoric Acid (HF), Ferric Chloride Etchant, or Cupric Chloride Etchant, impacts the processing difficulty. Let’s explore the key aspects of metal etching for titanium:

- Etching Difficulty: Titanium’s resistance to corrosion poses challenges during etching. Hydrofluoric Acid (HF) is highly corrosive and requires careful handling to achieve precise etching, while Ferric Chloride Etchant offers deep and well-defined patterns. Cupric Chloride Etchant provides controlled etching and is commonly used in electronic applications.

- Precautions: Due to the corrosive nature of etchants, strict safety precautions are essential. Proper ventilation, personal protective equipment, and adherence to handling protocols are necessary to prevent exposure to hazardous fumes and chemical burns.

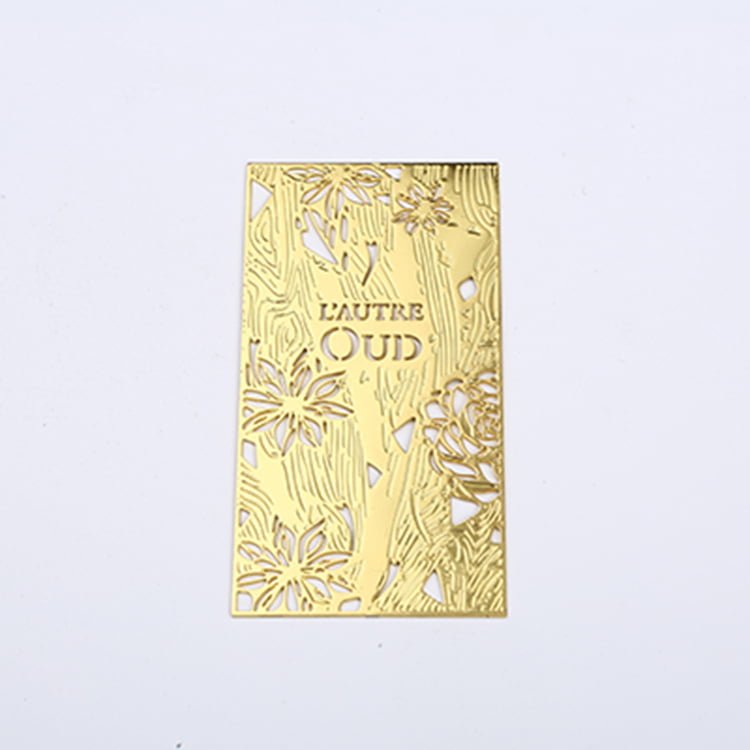

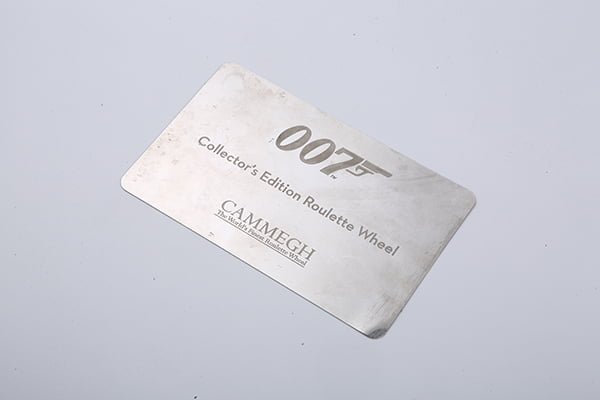

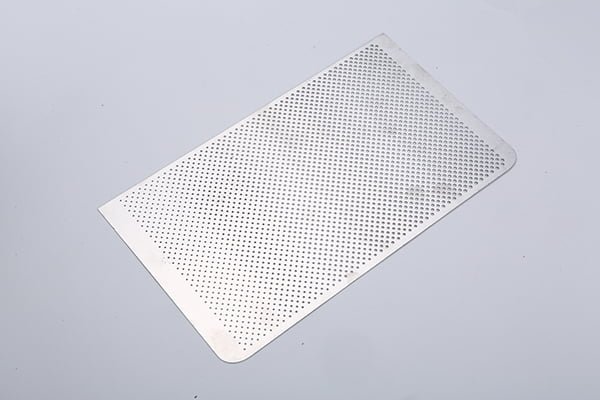

View our metal etching products

Titanium etching equipment

Photo Etching Titanium

Photo etching, also known as chemical milling, offers precise and intricate patterns on titanium surfaces. The process involves using light-sensitive masks to protect specific areas while etching the exposed regions. Let’s explore the key aspects of photo etching for titanium:

- Processing Difficulty: Photo etching demands exceptional accuracy and control. The photoresist must be carefully applied and developed to ensure accurate pattern transfer onto the titanium surface. The use of advanced photolithography techniques and skilled expertise is crucial to achieving the desired precision.

- Precautions: Handling of the photoresist requires a clean and controlled environment to prevent contamination. Careful adherence to processing times and temperatures during development ensures precise pattern transfer without overreaching or under etching.

Etching precision-machined titanium materials is a highly specialized process that requires a thorough understanding of the different types and alloys of titanium, as well as the intricacies of electroforming, surface treatment, metal cleansing, and etching techniques. By selecting the most suitable processes and adhering to stringent precautions, manufacturers and engineers can unlock the full potential of titanium, contributing to innovation and progress in a wide range of industries.

how to etch Titanium?

Etching Titanium Process Guideline

| Metal Alloy | Etchant | Etching Temperature (°C) | Etching Concentration (%) | Estimated Etching Depth (microns) | Etching Quality |

|---|---|---|---|---|---|

| Etching Pure Titanium | Hydrofluoric Acid (HF) | Room temperature | 5% HF | 10-40 | High-quality (smooth) |

| Etching Titanium-Aluminum (Ti-Al) | Ferric Chloride Etchant | Room temperature | 10% FeCl3 | 10-50 | High-quality (smooth) |

| Etching Titanium-Nickel (Ti-Ni) | Cupric Chloride Etchant | Room temperature | 10% CuCl2 | 10-50 | High-quality (smooth) |

| Etching Titanium-Nickel (Ti-Ni) | Sodium Hydroxide (NaOH) | Room temperature | 10-20% NaOH | 10-50 | High-quality (smooth) |

The values provided are approximate and can vary depending on specific etching conditions, including exposure time and the condition of the titanium or titanium alloy surface. Always conduct test etches and adjust parameters as needed to achieve your desired results. Additionally, safety precautions should be followed when handling these chemicals, especially in the case of Hydrofluoric Acid.

If you have metal wet etching Titanium needs, please feel free to contact us.

FAQs

What metals can you use to customize my goods?

- Wet Etching Germanium

- Wet Etching Gallium Nitride (GaN)

- Wet Etching Indium

- Wet Etching Cobalt

- Wet Etching Tungsten

- Wet Etching Stainless Steel

- Wet Etching Aluminum

- Wet Etching Kovar

- Wet Etching Copper

- Wet Etching Steel

- Wet Etching Nickel

- Wet Etching Platinum

- Wet Etching Silver

- Wet Etching Rhodium

- Wet Etching Hafnium

- Wet Etching Vanadium

- Wet Etching Zirconium

- Wet Etching Titanium

- Wet Etching Niobium

- Wet Etching Tantalum

- Wet Etching Molybdenum

- Wet Etching Brass

- Wet Etching Rhenium

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.

Etching Titanium Samples