Wet Processing Equipment for Biomedical etching machine

At Xinxin Precision, we are not only a manufacturer of advanced chemical etching machines, but also a professional metal etching factory with years of hands-on production experience. This dual capability allows us to deeply understand every detail of the etching process—from chemical formulation and flow control to real-world product performance—ensuring that our equipment is optimized for true industrial use. By combining in-house manufacturing with practical etching expertise, we deliver machines and processing solutions that are both technically refined and proven in actual production environments.

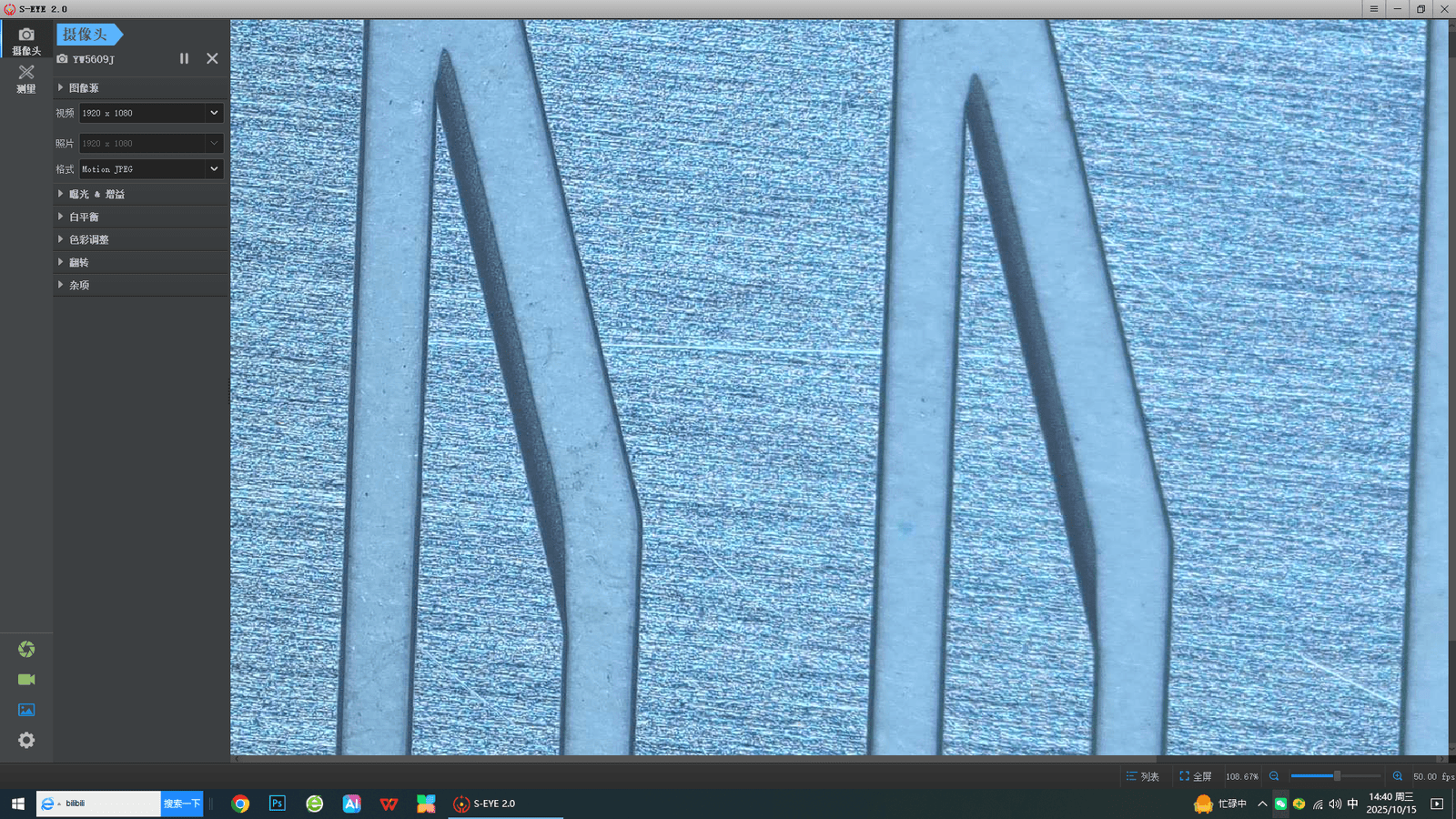

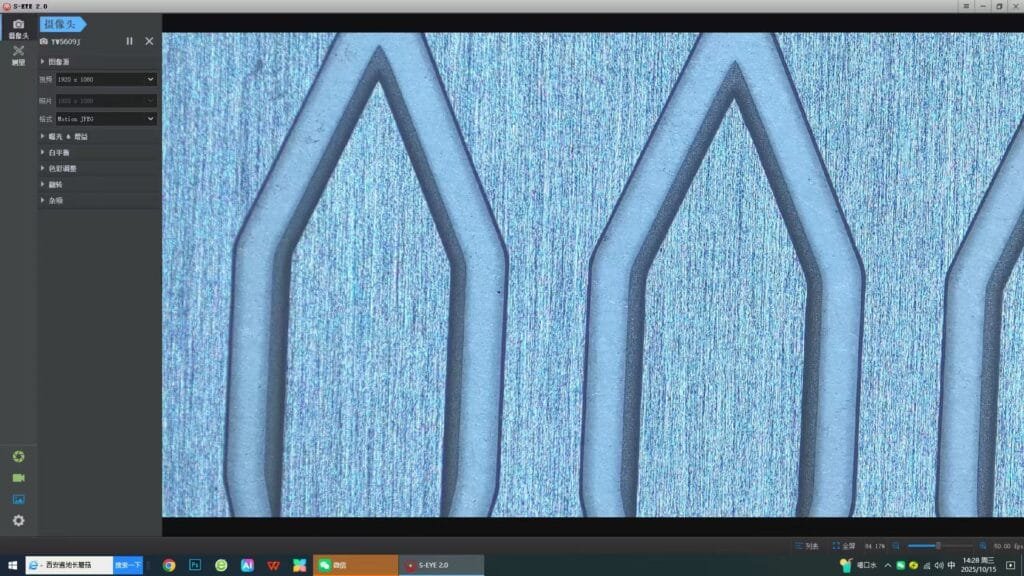

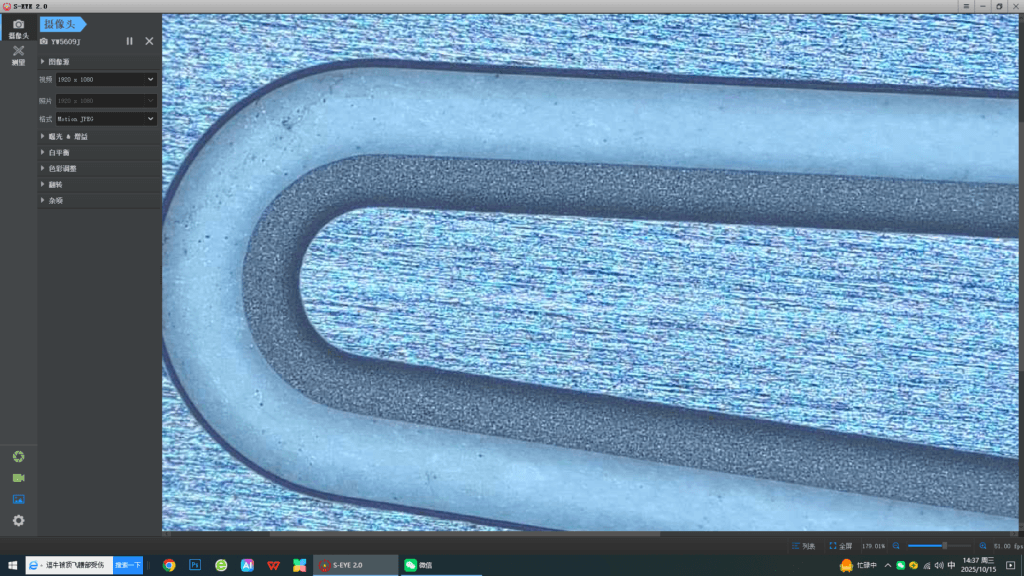

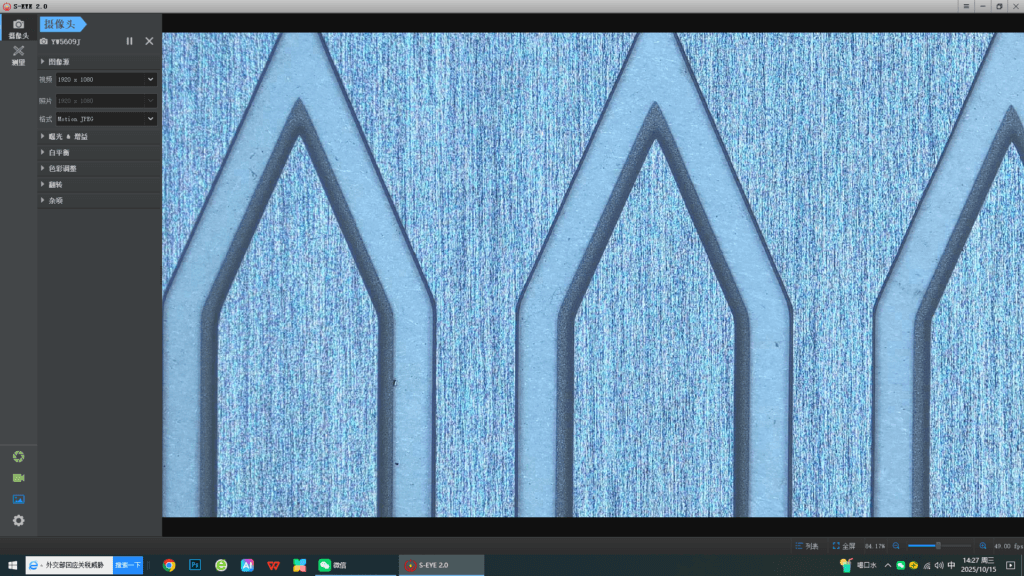

Biomedical blades

Biomedical blades

Selling Price:

$4800.00/m

Table of Contents

Supported Materials

- Stainless Steel (304, 316L, 420, etc.)

- Titanium and Titanium Alloys

- Nickel-based Alloys

- Special Surgical-Grade Metals

Applications

- Surgical blades and scalpels

- Medical razor blades

- Diagnostic micro-blades

- Laboratory micro-cutting tools

- Biopsy and tissue-sampling instruments

Let us produce for your Biomedical blades

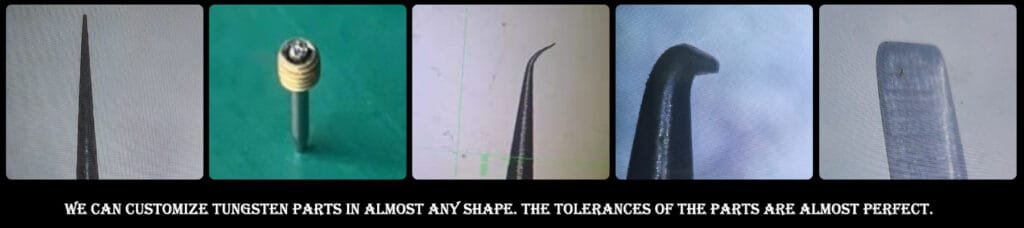

If you need biomedical blades produced directly, our engineering team can also provide complete custom blade manufacturing services. From material selection and photo mask design to precision chemical etching and final cleaning, we can deliver high-quality medical blades that meet your exact specifications and performance standards.

We can customize any micro parts.

Biomedical blade etching machine – Xinxin Precision

Xinxin Precision specializes in the design and manufacturing of biomedical blade etching machine equipment, offering advanced wet chemical processing systems for producing razor-sharp, high-precision blades used in medical and surgical applications. Our equipment is engineered to meet the demanding requirements of the biomedical industry, ensuring accuracy, cleanliness, and consistency in every etched component.

High Precision for Medical-Grade Blades

Our chemical etching machines are ideal for manufacturing surgical blades, scalpels, microtome blades, and other precision biomedical cutting instruments. Compared with laser cutting or mechanical grinding, chemical etching provides burr-free edges, uniform thickness, and precise pattern transfer without altering the metallurgical structure of the material.

Biomedical blade etching machine

| Biomedical blade etching machine – basic specifications | ||

| 1 | Process Flow | Feeding ➡ Etching ➡ Water Washing ➡ Discharging |

| 2 | Material | 12-25mm thick white PP, anti-static, Class A material, Xin Hengli protective color |

| 3 | Structure | Using Xin Hengli’s unique machine-engraved, internally inserted, double-sided welding technology, seamless single-plate dimensions |

| 4 | Reinforcement | Transmission baseplate and water tank baseplate are reinforced with PP square tubes |

| 5 | Dimensions | L: 5745 mm x W: 2485 mm x H: 2522 mm |

| 6 | Inlet and Outlet Directions | Left-in, right-out (viewed from the front window) |

| 7 | Drive Structure | Æ16D titanium rods, one-way, dual-drive |

| 8 | Conveyor Speed | 0-5 m/min (Mitsubishi inverter-adjustable) |

| 9 | Etching Rack | Independent swinging quick-release spray stand |

| 10 | Etching Nozzle Type | Quick-release high-flow fan nozzle |

| 11 | Conveyor Surface Height | 1194 ± 50 mm |

| 12 | Conveyor Surface Width | 810 mm |

| 13 | Roller Material | 40 mm PP conveyor wheel |

| 14 | Filtration System | Using the latest anti-spill double-layer filtration (full-pressure double-layer filtration and mesh bed filtration) |

| 15 | Control Panel | Independent control cabinet, Mitsubishi PLC + Weilun color touch screen |

| 16 | The transmission baseplate and water tank baseplate are reinforced with PP square tubes | 380 V 50 Hz AC, three-phase, five-wire, 24.3 kW |

Exclusive Free Etching Solution Formula

For every customer who purchases our equipment, we provide a free chemical etching solution formula after the installation and commissioning are completed. Our proprietary formula is uniquely developed by Xinxin Precision and is the result of years of technical research and production experience. Unlike standard etching solutions used by ordinary factories, our specialized formulation enables the precise and smooth etching required for biomedical blades and other high-precision medical components. With our exclusive chemical configuration, you can achieve sharp, burr-free edges and consistent surface quality that meet the strict standards of the medical industry.

Our metal etching equipment processing workshop

Features that can be added to a wet etching machine:

- Acid Controller – Popular for cupric chloride etchant

- Drying – Ensures products come out of the line dry.

- Inline Filtration – Results in fewer clogged nozzles and particles in solution.

- Ion Exchange – Saves water in rinse stations.

- pH Controller – Popular option for Alkaline etching. Standard on developing and resisting stripping lines.

- Ventilation Demister – Aids in condensation and recovery of evaporated process chemistry.

- Thin Material Transport – Transport very thin and flexible materials without the use of leaders.

- Drip Pan – Catches chemistry drops or spills

- Chiller Cooling System – Increased cooling capabilities.

- ORP Controller – Popular option for Cupric and Ferric etchers. Comes with a regeneration system.

- Specific Gravity Controller (IX) with Visual Baume – Prevents etchant Baume from getting too low or high.

- Recipe-Driven Operation – Eliminates product variation due to improper machine set-up.

- Data Collection and Archiving – Gives real-time and historical feedback analysis.

Wet Processing Equipment

Wet Chemical Etching Machine

The options do not stop there. WET ETCHING wet processing machines are modular — allowing you to configure your machine in any order you desire.