How do I select a photochemical etching service company if I need to use photochemical etching brass for a project right now?

Experience and Expertise:

Ensure that the company you choose has ample experience and expertise, particularly in dealing with brass.

They should understand the characteristics of brass to effectively perform photochemical etching.

Equipment and Technology:

Familiarize yourself with the equipment and technology the company uses. Modern equipment often provides higher precision and efficiency. Ensure that their equipment and technology align with the requirements of your project.

Quality Control:

Inquire about the company’s quality control processes. They should have rigorous quality control standards to ensure your project meets the expected quality standards.

Project Scale:

Consider the scale of your project. Some companies may be better suited for large production batches, while others specialize in small batches or custom projects. Choose a company that fits the scale of your project.

Delivery Time:

Understand the company’s delivery times. If you have time constraints, ensure that the company can complete the project on schedule.

Cost and Budget:

Lastly, consider costs and your budget. Discuss project costs with the company and ensure they align with your budget.

Photochemical Etching Service Specialists

No1:Dragon Etching

Dragon Etching are a dedicated team of experts specializing in Photochemical Etching services and manufacturing.

Why Choose Dragon Etching?

Dragon Etching stands out from other Photochemical Etching service providers in several key ways:

- In-House Machine Manufacturing: We are not just a service provider; we also manufacture Photochemical Etching machines. Click here to learn about the Photochemical Etching Equipment Selection Guide. This unique capability allows us to offer customized solutions, tailored to your specific needs. Whether you need our services or a customized DIV Photochemical Etching Machine, we have you covered.

- Advanced Laboratory Facilities: Our state-of-the-art laboratories are equipped with the latest machinery and technology, ensuring consistent and high-quality results for our clients.

- Rapid Turnaround: We understand the importance of timely project completion. Our streamlined processes enable us to offer some of the fastest turnaround times in the industry, ensuring your projects are completed efficiently and on schedule.

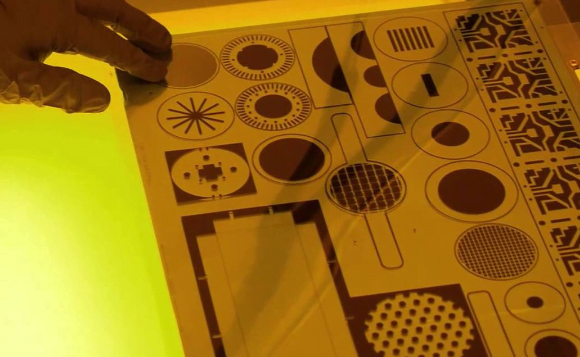

No2:Wet Etching

In the realm of Photochemical Etching, Wet Etching is a prominent and indispensable process. It’s a method that involves selectively removing material from a substrate using chemical solutions. This process is widely employed in various industries for its ability to precisely define intricate patterns on different materials, making it essential for applications such as microelectronics, semiconductor fabrication, and precision engineering.

Meet WET ETCHING – The Pioneers of Wet Etching

In the world of Wet Etching, one company stands out as a true industry leader – WET ETCHING. With a rich history of innovation and a commitment to excellence, WET ETCHING has redefined the standards of wet etching in the world of photochemical processes.

Leadership in Wet Etching

Cutting-Edge Technology: WET ETCHING has consistently pushed the boundaries of wet etching technology. They employ cutting-edge machinery and state-of-the-art chemical solutions to achieve precision and efficiency that surpass industry norms. Their dedication to research and development keeps them at the forefront of technological advancements in the field.

Experienced Team: At WET ETCHING, it’s not just about the technology; it’s also about the people. Their team of seasoned experts boasts extensive experience in wet etching, allowing them to tackle complex projects with finesse. Their skillful hands and keen eyes ensure that each etching process is executed flawlessly.

Custom Solutions: Recognizing that each project has its unique requirements, WET ETCHING specializes in providing tailored solutions. Whether it’s semiconductor components, microelectromechanical systems (MEMS), or intricate precision parts, WET ETCHING can design a wet etching process that perfectly aligns with the specific demands of the project.

Stringent Quality Control: The hallmark of WET ETCHING’s leadership is their unwavering commitment to quality control. Every product that leaves their facility undergoes rigorous testing and inspection to guarantee precision and reliability. Clients can trust that their projects are in safe hands when partnering with WET ETCHING.

Collaborative Approach: WET ETCHING’s success isn’t just a testament to their technology and expertise; it’s also a result of their collaborative approach. They actively engage with their clients, fostering a partnership that ensures project success. By understanding their clients’ needs, challenges, and goals, they deliver wet etching solutions that exceed expectations.

In the world of wet etching, WET ETCHING is more than just a company; it’s a beacon of innovation and precision. Their leadership in photochemical etching is a testament to their unwavering dedication to pushing the boundaries of what’s possible. With cutting-edge technology, a skilled team, and a commitment to quality, WET ETCHING continues to shape the future of wet etching, one precise etch at a time.

No3:Precision Micro

Pioneers in photochemical etching. Market-leading photochemical machining company supplying precision-etched metal components to exacting specifications

The leading photochemical etching service for 60 years.

From stainless steels to nickel, copper, aluminium and more, we’ve been innovating photochemical machining technology for more than half a century.

We produce and supply millions of precision photo-etched components every year for industry-leading companies all over the world, stretching the boundaries of micro-precision component manufacture.

No4:Masteretch

Masteretch design and manufacture chemical etching equipment. From small-scale laboratory machines to large mass production etching lines, Masteretch serve a wide range of industries.

Beyond our core range of equipment we can also deliver tailored etching solutions designed to meet your unique requirements. Our expertise in fabrication and design allows us to offer a high degree of customization to help our customers achieve their objectives.

Masteretch systems are expertly designed, assembled in-house at our UK facility and fully tested prior to shipping. Our equipment is designed to operate at maximum efficiency and for long term use at high volume production levels. Masteretch systems are renowned for their dependability, low operating and maintenance costs, making Masteretch the equipment supplier of choice for many of the world’s leading etching companies.

No5:ADVANCED METAL ETCHING, INC.

We understand that the success of your project depends on delivering quality parts manufactured at the right cost and within your timeline. We know the challenges of choosing the proper manufacturing process for your parts, and we’re here to help you navigate the process quickly and confidently.

Our custom metal parts manufacturing facility specializes in the photo etching and laser cutting processes. Both provide the highest quality and precision for today’s part designs. With a keen eye for spotting potential issues, we ensure that your part is the first step toward a successful product launch, and we strive to eliminate unnecessary delays.

Our team is dedicated to providing exceptional service and responsive attention to keep you in control of your project and out of the dark.

No6:Interplex

As a world leader in designing and manufacturing interconnect and mechanical products, we solve complex customer challenges and bring ideas to life.

We create value by helping our customers reduce their Total Cost of Ownership through utilizing our technical expertise, vertically integrated manufacturing, global footprint and innovative technologies enabling us to deliver interconnect products shaping the fields of Mobility, Medical, and Information & Communications.

No7:Elcon

Whether in fully custom prototyping or high-volume production, we employ team-wide expertise in each of our core disciplines to provide precision parts that are built to succeed.

In addition to collaborating on outside-the-box applications, we also specialize in the manufacture of key precision products, all designed and built for critical applications.

No8:TMN

Founded in 2011, TMN Etch specializes in photo chemical etching (PCE), serving worldwide companies with custom precision metal parts to meet their needs. The photo chemical etching process can be applied in a wide range of raw materials, such as stainless steel 300 series, brass alloy, copper alloy, aluminum, chrome, and other special metal alloys. With the photo chemical etching process, TMN Etch provides prototypes according to your drawings within 3 days without any tooling cost, and you can modify your designs whenever you want. Free samples, shorter lead time, tighter tolerance, higher precision, and lower cost for high volume production are the promises of TMN Etch to you.