Screen printing engraving of stainless steel is a precise process that requires specialized equipment and meticulous attention to detail. This article explores the essential equipment required, estimated costs, surface treatment processes, and the selection of engraving solutions. Understanding these key elements will help you make informed decisions for your stainless steel engraving projects.

Table of Contents

- Equipment and Cost Evaluation

- Surface Treatment Processes and Equipment

- Selection of Stainless Steel Engraving Solutions

- Stainless Steel Grades and Engraving Parameters

- Screen Printing Engraving Process

- If you need a OEM factory to realize your project, please do not hesitate to contact us.

- Wet Chemical etching

Equipment and Cost Evaluation

For a screen printing engraving facility processing 5000 square meters per month, the following equipment is necessary:

| Equipment Name | Estimated Price | Usage Description |

|---|---|---|

| Cleaning line | $32,000 | Used to clean the stainless steel surface before engraving. This ensures that any contaminants are removed, providing a clean surface for the engraving process. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com | ||

| Screen printing line | $25,000 | Applies a screen-printed resist to the stainless steel surface, creating the desired pattern to be engraved. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com | ||

| Drying line | $18,000 | Dries the screen-printed resist, preparing it for the engraving process. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com | ||

| Developing line | $40,000 | Develops the screen-printed stainless steel by removing the unexposed resist, revealing the areas to be engraved. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com | ||

| Stainless Steel Engraving line | $100,000 | The core of the process, this equipment engraves the exposed stainless steel areas using the selected engraving solution. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com | ||

| Stripping line | $70,000 | Removes the remaining resist after the engraving process, leaving behind the final engraved stainless steel pattern. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com |

Surface Treatment Processes and Equipment

Surface treatment is essential for preparing the stainless steel surface and achieving the desired finish. Here are recommended surface treatment processes and equipment:

| Equipment Name | Estimated Price | Usage Description |

|---|---|---|

| Grinding machine (Automatic) | $140,000 | Used to grind the stainless steel surface, ensuring a smooth and uniform finish before engraving. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com | ||

| Grinding machine (Manual) | $70,000 | Provides a manual grinding option for smaller batches or specialized applications. |

| Manufacturer: Dragonetching <br> Manufacturer Website: www.dragonetching.com |

Selection of Stainless Steel Engraving Solutions

Engraving stainless steel using chemical solutions involves careful selection of etchants. The choice depends on the specific application and desired engraving characteristics. Here are some commonly used etchants for stainless steel:

- Copper Chloride (CuCl2) Engraving Solution: Effective for stainless steel, copper chloride provides a controlled engraving rate and is commonly used for detailed and intricate designs.

Stainless Steel Grades and Engraving Parameters

The table below lists different stainless steel grades, along with their engraving parameters and estimated results. All samples have the same thickness, width, and length for uniform comparison.

| Stainless Steel Grade | Chemical Engraving Temperature (°C) | Chemical Engraving Solution Concentration (%) | Estimated Chemical Engraving Depth (µm) | Chemical Engraving Quality |

|---|---|---|---|---|

| 304 | 45 | 40 | 20 | High |

| 316 | 45 | 40 | 18 | High |

| 430 | 45 | 40 | 22 | Medium |

| 201 | 45 | 40 | 25 | Medium |

| 410 | 45 | 40 | 15 | High |

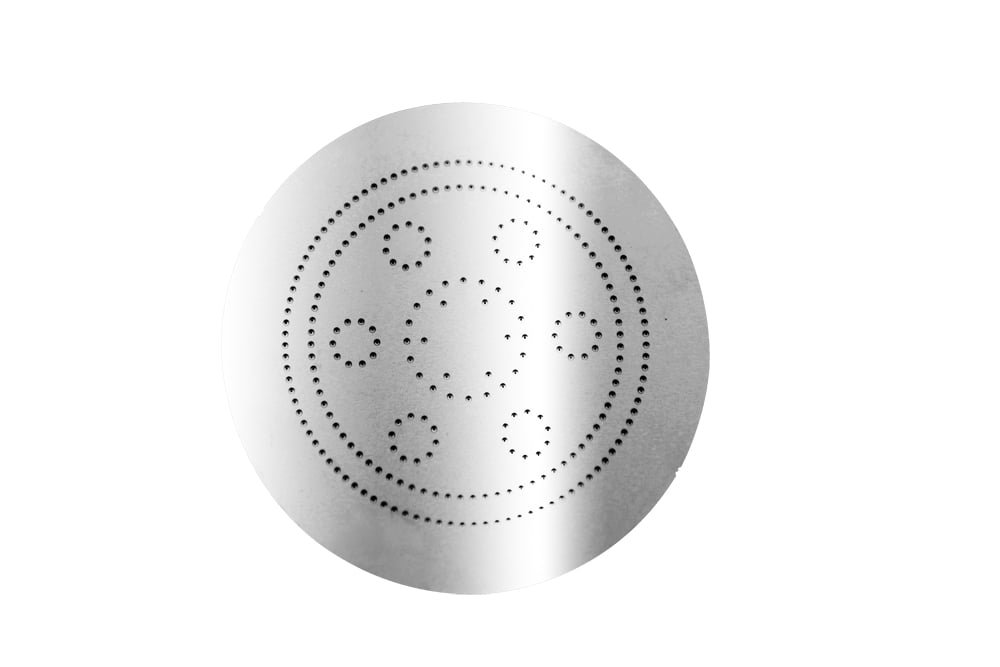

Screen Printing Engraving Process

The stainless steel engraving process involves several detailed steps to ensure precision and quality:

- Cleaning:

- Step: Clean the stainless steel surface using the cleaning line.

- Detail: This step removes all contaminants, ensuring the stainless steel is ready for further processing.

- Screen Printing:

- Step: Apply resist paint using the screen printing line.

- Detail: The screen-printed resist protects areas of the stainless steel that should not be engraved.

- Drying:

- Step: Dry the resist-covered stainless steel using the drying line.

- Detail: This ensures the resist is firmly adhered to the stainless steel surface.

- Developing:

- Step: Develop the screen-printed stainless steel using the developing line.

- Detail: This removes the unexposed resist, revealing the areas to be engraved.

- Engraving:

- Step: Engrave the stainless steel using the stainless steel engraving line with the selected engraving solution.

- Detail: The engraving solution removes the exposed stainless steel, creating the desired pattern.

- Stripping:

- Step: Remove the remaining resist using the stripping line.

- Detail: This leaves behind the final engraved stainless steel pattern, ready for any further processing.

By understanding the intricacies of the screen printing engraving process for stainless steel, including the necessary equipment, surface treatments, and engraving solutions, you can make informed decisions and achieve high-quality results in your stainless steel engraving projects.

If you need a OEM factory to realize your project, please do not hesitate to contact us.

Wet Chemical Etching Company is a leading provider of wet chemical etching services, dedicated to delivering high-quality and precise etching solutions for the semiconductor, microelectronics, and precision manufacturing industries. Equipped with advanced technology and state-of-the-art equipment, our company can handle various materials and complex pattern requirements. Our professional team has extensive experience and expertise, ensuring that every project is delivered on time and meets the highest quality standards. Whether for prototype development or large-scale production, Wet Chemical Etching Company is committed to customer satisfaction, offering customized and efficient services to help your products succeed in the market.