Green Chemistry in Aluminum Etching

The aluminum etching industry is increasingly adopting sustainable practices to minimize its environmental impact. Green chemistry has become a focal point in this transition, encouraging the use of safer, less toxic chemicals and processes that reduce waste, energy consumption, and emissions. These practices align with the growing demand for eco-friendly solutions in the manufacturing sector, particularly among ESG officers and eco-conscious brands.

Transition to Less Toxic Etchants (Citric Acid Blends)

One of the significant shifts in aluminum etching has been the transition from traditional toxic etchants like ferric chloride and nitric acid to more eco-friendly alternatives. Citric acid blends have become a popular option for etching aluminum, offering several advantages in terms of both safety and environmental impact.

| Etchant | Traditional (e.g., Ferric Chloride) | Eco-friendly (e.g., Citric Acid Blends) |

|---|---|---|

| Toxicity | High (requires special handling) | Low (safer for workers) |

| Environmental Impact | High (harmful to ecosystems) | Low (biodegradable and non-toxic) |

| Efficiency | Effective but requires more handling | Comparable etching results with reduced risks |

| Cost | Higher due to safety measures | Lower long-term costs due to reduced disposal needs |

Switching to citric acid blends helps manufacturers reduce their use of hazardous chemicals, making the etching process safer for both workers and the environment. Moreover, it significantly lowers the risk of chemical spills and pollution, supporting green manufacturing.

Closed-Loop Etchant Regeneration Systems

Implementing closed-loop etchant regeneration systems is a crucial step in reducing the waste produced during the etching process. These systems recapture, filter, and regenerate the spent etchant, making it reusable for subsequent etching cycles. This minimizes the need for fresh chemicals and reduces the volume of waste chemicals that need to be disposed of.

Waste Reduction Strategies

Chemical etching can be waste-intensive if not managed properly. However, by adopting effective waste reduction strategies, manufacturers can minimize their environmental footprint.

Recycling Spent Aluminum Etchant

Spent aluminum etchant can be neutralized, filtered, and recycled in a closed-loop system, reducing the need for new chemicals. This process not only lowers chemical costs but also reduces harmful chemical disposal, promoting a zero-waste production model.

Scrap Metal Reuse Programs

Another critical aspect of waste reduction in aluminum etching is the reuse of scrap metal. The metal waste produced during the etching process can be recycled, reducing the need for new materials. This helps conserve natural resources and lowers the carbon footprint of the production process.

| Waste Type | Traditional Disposal | Sustainable Practice |

|---|---|---|

| Scrap Aluminum | Disposed of or sent to landfills | Recycled back into production or sold as scrap |

| Spent Etchant | Sent to hazardous waste facilities | Recycled and reused in closed-loop systems |

Recycling scrap metal and etchant not only reduces waste but also contributes to a circular economy, where materials are continuously reused rather than discarded.

Energy Efficiency

Energy consumption is a critical factor in the environmental impact of aluminum etching. By adopting low-energy etching machines and renewable energy sources, manufacturers can significantly reduce their carbon footprint.

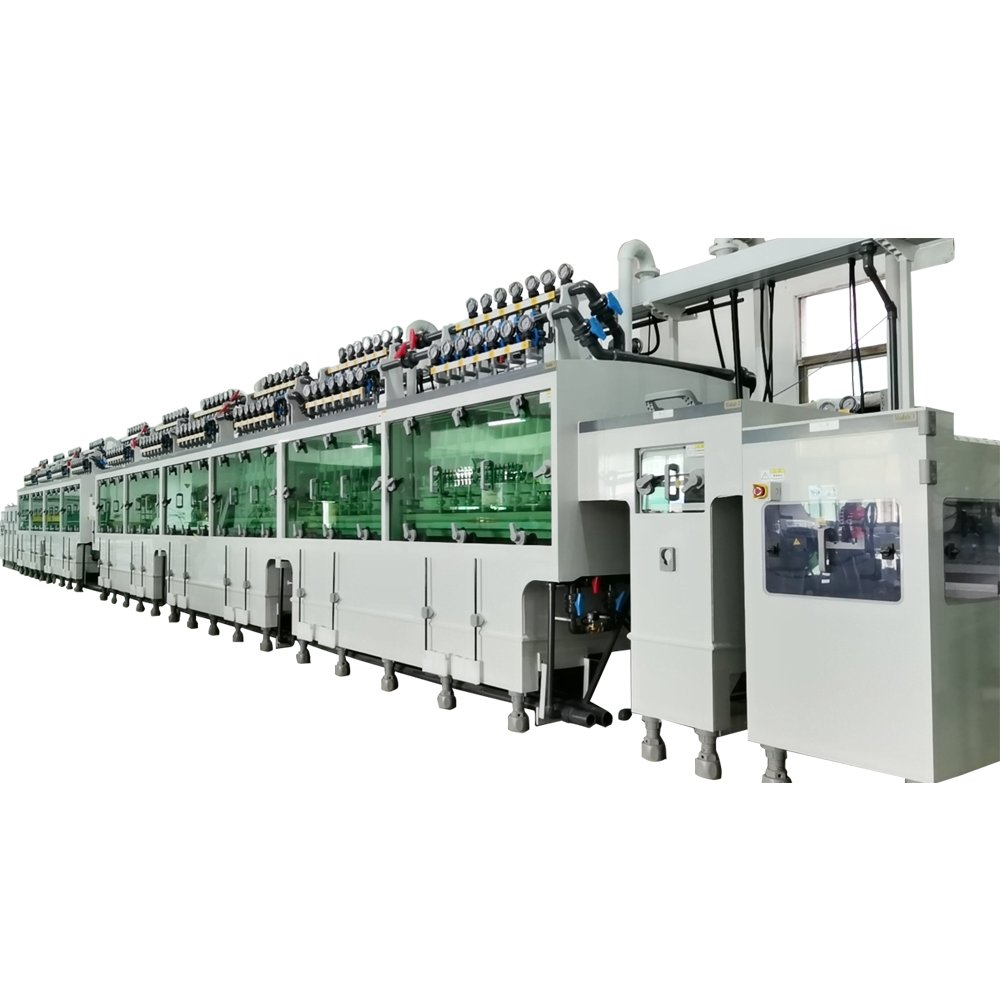

Low-Energy Etching Machines

Advancements in low-energy etching machines allow for the same level of precision and quality in aluminum etching while consuming less energy. These machines are designed to operate more efficiently, using less power and producing fewer emissions during the etching process. They’re a crucial investment for manufacturers committed to reducing energy use and achieving sustainability goals.

Solar-Powered Facilities for Clean Production

To further decrease emissions, some aluminum etching facilities are transitioning to solar-powered production models. By installing solar panels on-site, these companies can generate renewable energy to power their etching operations, significantly lowering their dependence on fossil fuels and reducing overall greenhouse gas emissions.

| Energy Source | Traditional | Solar-Powered |

|---|---|---|

| Energy Cost | High (due to reliance on grid power) | Low (once solar system is installed) |

| Carbon Emissions | High (fossil fuel reliance) | Zero (clean, renewable energy) |

| Sustainability | Moderate (relies on non-renewable sources) | High (sustainable, renewable energy) |

By shifting to solar power, manufacturers can contribute to a greener future, enhancing their ESG (Environmental, Social, and Governance) profile while cutting long-term energy costs.

Certifications and Compliance

To ensure that sustainable practices are upheld, manufacturers must meet certifications and compliance standards. These certifications demonstrate a commitment to environmental responsibility and help companies align with global sustainability initiatives.

Meeting ISO 14001 and REACH Standards

Compliance with standards such as ISO 14001 (Environmental Management) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) ensures that aluminum etching operations are environmentally friendly and comply with global regulations. These certifications also improve the company’s reputation among eco-conscious consumers and stakeholders.

- ISO 14001 ensures that companies are actively reducing their environmental impact and improving sustainability.

- REACH compliance ensures that the chemicals used are safe for human health and the environment, furthering green chemistry practices.

Conflict-Free Aluminum Sourcing

For manufacturers looking to meet sustainable sourcing standards, using conflict-free aluminum is an essential practice. This involves ensuring that the aluminum used in production is sourced responsibly, without contributing to environmental destruction or human rights violations.

Case Study: Zero-Waste Etching Facility

Leading manufacturers are adopting zero-waste practices in their chemical etching operations, achieving significant improvements in material utilization and waste reduction.

Achieving 90% Material Utilization Through Process Optimization

A prominent zero-waste etching facility has managed to achieve 90% material utilization by optimizing their etching process and improving scrap metal recycling. By investing in closed-loop systems and efficient material management, this facility has dramatically reduced its material waste, contributing to a more sustainable and cost-effective production model.