Understanding Acid Etching Stainless Steel and Electrolytic Metal Etching

When you hear the term acid etching stainless steel, your first thought might be Electrolytic Metal Etching. While both processes are related to the same general concept of etching, they are actually distinct techniques with key differences that set them apart.

Electrolytic Metal Etching is often used for marking metal surfaces, and its results are quite similar to those achieved by a laser marking machine. However, despite their similar outcomes, these two methods have different underlying processes and applications.

What Is Electrolytic Metal Etching?

Electrolytic Metal Etching is a precise, controlled process that uses low-voltage electric currents to etch designs onto metal surfaces. The method involves passing the electric current through a pre-printed stencil, transferring the current through the stencil’s gaps using a harmless electrolyte fluid. This results in the etching of a thin layer of the surface material, leaving behind a contrasting dark finish on the metal.

Typically, the etching process takes just 2-3 seconds, depending on several factors, including the type of material, and the size or complexity of the design being etched. This rapid marking capability makes it highly effective for a wide variety of applications, from part identification to intricate patterns.

Electrolytic Metal Etching is especially useful for creating durable markings on materials that can withstand 1000-3000 cycles of etching, making it suitable for both high-volume production and custom jobs.

Versatility in Stencil Options for Metal Etching

One of the major advantages of Electrolytic Metal Etching is the wide range of stencil options available. These stencils can be customized to suit virtually any kind of design or marking requirement, ensuring versatility in your etching processes. Common applications include:

- Plain Text or Numbers: Whether you need part numbers or other identifiers, this method is highly effective for clean and precise text markings.

- High-Resolution Logos: For companies looking to brand their products, Electrolytic Metal Etching is capable of transferring high-quality logos and designs with fine details.

- Serial Numbering: Ideal for parts that require unique serial numbers, ensuring easy tracking and identification in a variety of industries.

- Part Numbers: Etch part numbers directly onto products to improve traceability and streamline inventory management.

- Patterns or Grid Markings: If your application requires complex designs or patterns, Electrolytic Metal Etching can easily handle those as well.

By choosing the right stencil for your project, you can achieve precise and professional results in a fraction of the time compared to other traditional marking methods.

Affordable Metal Marking & Etching Systems

When considering a Metal Marking & Etching System, you’ll be pleased to know that you can purchase a complete, high-quality system at an affordable price. These systems are ideal for businesses or individuals looking for a cost-effective alternative to more expensive technologies like laser marking machines.

In comparison to a laser marking system, which typically costs around $2000 or more, an Electrolytic Metal Etching system offers more versatility at a significantly lower price point. Unlike laser machines, which are often limited to desktop versions, Electrolytic Metal Etching systems are available in more flexible configurations that allow for a broader range of applications.

Laser sources, such as fiber lasers, do have advantages, such as a projected lifespan of up to 100,000 hours and the ability to etch most metals and non-metals, including slate, hard plastics, artificial leather, and colored acrylic. Fiber lasers also enable easy engraving of curved surfaces, making them a great choice for those who need to perform curved engravings or handle more complex etching tasks.

However, for high-volume, repetitive marking jobs, especially those requiring a lower upfront investment, an Electrolytic Metal Etching system offers a more affordable and equally effective solution. Fiber lasers may be ideal for long-term investments and large-scale production, but for those focused on precision metal marking with minimal upfront costs, Electrolytic Metal Etching remains a strong contender.

Exploring Chemical Etching

Now, let’s delve into chemical etching, another powerful method for producing high-quality metal markings. Chemical etching is an ideal option for high-volume production, providing an effective combination of both laser engraving and marking benefits.

While laser engraving offers precision, chemical etching often outperforms lasers in terms of speed, cost-efficiency, and precision. The chemical etching process works by using a chemical solution to etch metal, creating clean, crisp markings without the need for high-powered lasers or complex machinery.

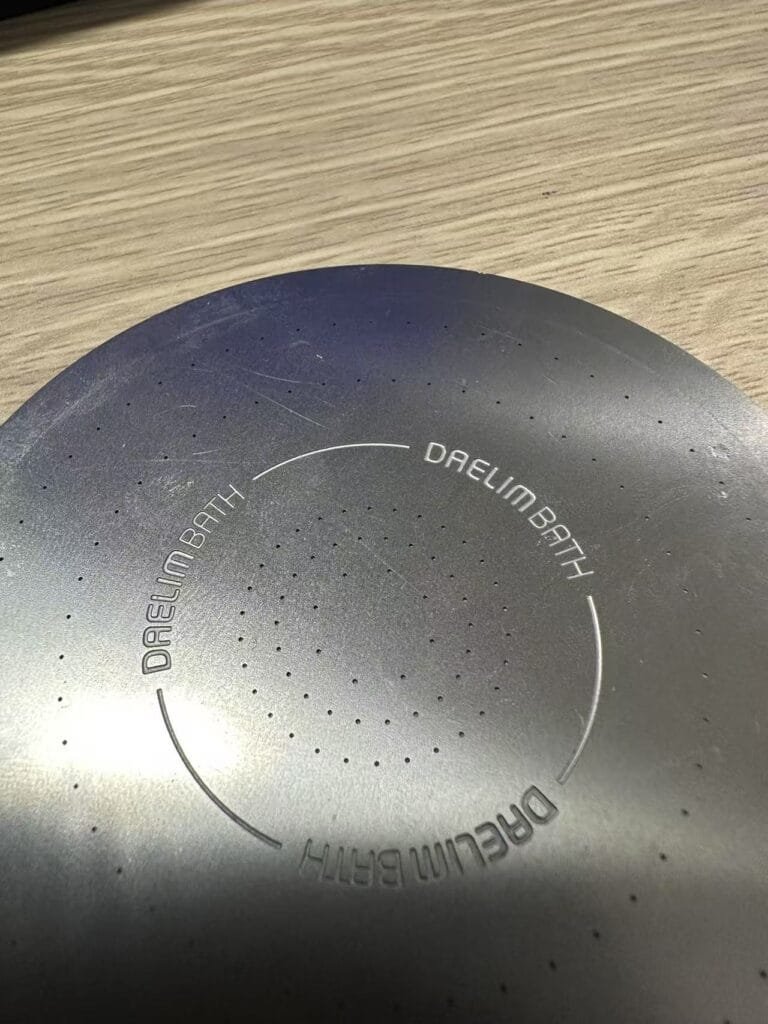

As you can see from the above picture, this is a gasket in a shower head, and the entire process of this gasket is chemically etched.

And the price of this gasket is very cheap.

One of the primary advantages of chemical etching over laser marking is its higher etching speed, which enables faster turnaround times for large batches. In addition to faster processing speeds, chemical etching is more cost-effective, offering lower operational costs compared to laser etching systems, which often require expensive maintenance and consumables.

Why Choose Chemical Etching?

Beyond the financial and speed advantages, chemical etching also delivers superior precision. The chemical process can produce highly detailed designs with incredible accuracy, even on intricate or small-scale parts. Additionally, the process is less prone to wear over time, ensuring consistent quality across multiple etching cycles.

Another benefit of chemical etching is its ability to produce aesthetically pleasing results. While laser markings can sometimes appear as overly harsh or uneven, chemical etching allows for smooth, well-defined lines and a finish that enhances the overall visual appeal of the product. This is particularly important in industries where both functionality and appearance matter, such as in aerospace, automotive, or high-end consumer goods.

The Ideal Solution for Metal Marking

Both Electrolytic Metal Etching and chemical etching offer unique benefits depending on your production needs. While laser etching remains a strong choice for high-volume, repeatable jobs that require complex engraving, Electrolytic Metal Etching and chemical etching present more affordable and efficient alternatives for producing high-quality, precise markings on metal surfaces.

For those seeking flexibility, low-cost investment, and the ability to handle a range of applications, an Electrolytic Metal Etching system could be the perfect solution. If you prioritize speed, cost efficiency, and clean, high-resolution markings, chemical etching may be the ideal choice to meet your needs.

No matter which process you choose, you can rely on the advanced capabilities of modern etching technologies to produce superior results that enhance both the functionality and aesthetics of your products.