📦 Wholesale Pricing Table, Quantity Discounts

| Quantity | Unit Price |

|---|---|

| 250 PCS | $0.90~$1.20/PCS |

| 500 PCS | $0.90~$1.20/PCS |

| 1,000 PCS | $0.70~$1.00/PCS |

| 2,000 PCS | $0.60~$0.99/PCS |

Want to get your metal business cards at a lower price? Contact us now to get the lowest discount! Or contact our sales representatives directly via WhatsApp +86 15999653684

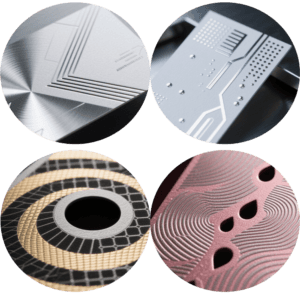

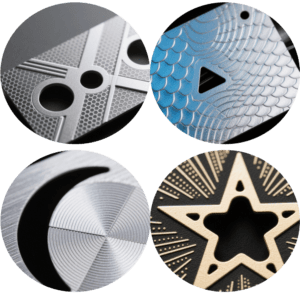

You can customize any pattern

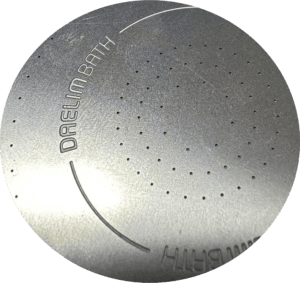

WET Products: Direct Manufacturing and Bulk Discounts

WET Products stands out as a leading manufacturer of stainless steel nameplates. With direct manufacturing capabilities, they offer substantial bulk discounts, making them an ideal partner for companies and engraving shops that need large quantities of blank plates for custom engraving.

By sourcing directly from WET Products, you can ensure consistent quality and receive quick turnarounds, ensuring that your nameplates are produced to your specifications and delivered on time.

Laser Engraving vs. Chemical Etching for Stainless Steel Business Cards

Laser engraving uses a high-powered laser to burn or mark the surface of the stainless steel. It creates deep, sharp lines and is great for bold text or simple designs. However, it can leave burn marks or discoloration and may not be ideal for fine details.

Chemical etching, on the other hand, uses a controlled acid or chemical process to remove layers of metal. It allows for very fine, detailed, and even multi-depth designs without heat damage. The result is a clean, smooth finish that’s great for logos, textures, and custom artwork.

In short:

Laser engraving = fast, deep, but limited detail.

Chemical etching = precise, clean, and great for intricate designs.

Selective etching and semi-etching in stainless steel

You can find that the surface of the metal after etching is very beautiful.

On the contrary, laser engraving requires secondary polishing to complete

60% cheaper than laser engraving

Metal nameplate stainless steel business card etching Samples

Why Choose WET Products:

- Direct Manufacturing: No middlemen means lower costs and better quality control.

- Bulk Discounts: Save more when purchasing large quantities of blank stainless steel nameplates.

- Compatibility with Engraving Shops: Ideal for businesses that need custom blanks ready for engraving.

Use Cases for Custom Stainless Steel Nameplates

Machinery ID Tags

Stainless steel nameplates are an excellent choice for identifying machinery and equipment in industrial settings. Their durability ensures they won’t fade or degrade over time, even in harsh environments like factories or construction sites.

- Example: Heavy machinery in manufacturing plants or warehouses with easily readable, long-lasting identification tags.

High-End Product Branding

For products requiring a premium look, such as luxury goods or high-end equipment, stainless steel nameplates serve as a sophisticated branding tool. Laser-etched corporate logos and product information can enhance the perceived value of your product.

- Example: Custom nameplates for luxury cars, designer appliances, or high-tech gadgets.

Advantages of choosing WET for your processing:

- Precision Technology: Utilizing etching processing technology, WET achieves high accuracy, up to ±0.01mm (accuracy varies with material thickness). With 12 years of experience, we are a trusted manufacturer known for professional precision etching processing.

- Versatility in Patterns: WET etching processing imposes no restrictions on complex patterns or arbitrary geometric figures. Regardless of the complexity of hole shapes or patterns, they can be formed in a single step without increasing production costs.

- Double-Sided Simultaneous Processing: WET’s chemical etching is a double-sided simultaneous processing technology. The product surface (front and back) is smooth, free from bulges, pits, burrs, warping, and deformation. No grinding or polishing is required after flattening.

- Fine Dimensions and Accurate Positioning: WET etching processing offers fine dimensions (aperture 0.1mm, line width 0.1mm), accurate positioning (±0.03mm), and uniformity.

- Efficient Production Cycle: WET boasts a short production cycle, quick response, and easy design modification. Our team comprises 17 professionals specializing in etching technology, including senior technicians with over 15 years of experience.

- Fast Prototyping: WET’s proofing is swift, typically completed within 1-2 working days, tailored to specific product requirements.

- Automated Production Lines: WET Etching operates three automated etching production lines, ensuring high output to meet batch processing and customized microporous mesh production orders.

- Comprehensive Auxiliary Services: WET provides additional services such as stamping, welding, fuel injection, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc. This comprehensive range caters to diverse product needs, offering a convenient and fast one-stop service for processing.

If you have metal wet etching needs, please feel free to contact us.

FAQs

What metals can you use to customize my goods?

- Wet Etching Germanium

- Wet Etching Gallium Nitride (GaN)

- Wet Etching Indium

- Wet Etching Cobalt

- Wet Etching Tungsten

- Wet Etching Stainless Steel

- Wet Etching Aluminum

- Wet Etching Kovar

- Wet Etching Copper

- Wet Etching Steel

- Wet Etching Nickel

- Wet Etching Platinum

- Wet Etching Silver

- Wet Etching Rhodium

- Wet Etching Hafnium

- Wet Etching Vanadium

- Wet Etching Zirconium

- Wet Etching Titanium

- Wet Etching Niobium

- Wet Etching Tantalum

- Wet Etching Molybdenum

- Wet Etching Brass

- Wet Etching Rhenium

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.