Steel, known for its exceptional strength and versatility, is a widely used material in precision machining. The etching process plays a crucial role in shaping and patterning steel components for various applications.

Our Packages

- From 1000pcs

- Samples from 100pcs

- Approx. 30 days (may vary depending on the difficulty of the drawing)

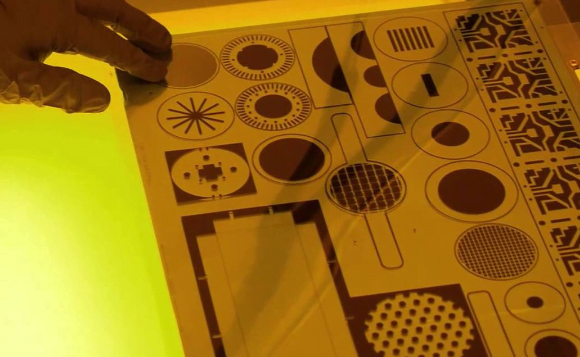

View our Steel etching production facility

View or download our Photochemical Metal Etching White Paper How-to Guide

Types of Steel and Etching Steel Characteristics

Steel encompasses a broad range of alloys, each possessing distinct properties catering to specific applications. Some common types of steel include:

- Carbon Steel: This alloy contains primarily iron and carbon, making it cost-effective and suitable for general applications. Etching carbon steel is relatively straightforward and can achieve precise results.

- Stainless Steel: Stainless steel contains chromium, which provides excellent corrosion resistance. Etching stainless steel requires specialized etchants to maintain its corrosion resistance and achieve intricate patterns.

- Tool Steel: Tool steel is characterized by its high hardness and wear resistance, making it suitable for cutting tools and molds. Etching tool steel demands precise control to achieve desired patterns without compromising its mechanical properties.

- Alloy Steel: Alloy steel incorporates additional elements such as nickel, molybdenum, or vanadium to enhance specific properties. Etching alloy steel requires consideration of the specific alloy composition to achieve the desired results.

Advantages and Disadvantages of Steel Alloys in Wet Processing

Etching steel alloy possesses unique advantages and disadvantages when it comes to wet processing and etching:

- Carbon Steel: Advantages: Cost-effective, easy to etch with common etchants, and suitable for general applications. Disadvantages: Limited corrosion resistance and lower mechanical properties compared to other alloys.

- Stainless Steel: Advantages: Excellent corrosion resistance, suitable for applications requiring hygiene and aesthetics. Disadvantages: Requires specialized etchants and precise control due to its corrosion-resistant properties.

- Tool Steel: Advantages: High hardness and wear resistance, ideal for cutting tools and molds. Disadvantages: Challenging to etch without compromising mechanical properties.

- Alloy Steel: Advantages: Tailored properties for specific applications, offers versatility. Disadvantages: Etching may require unique etchants depending on the alloy composition.

Metal Etching Steel

Metal etching precisely shapes and patterns steel components for various applications. The wet processing method employs metal etching machines and specific chemical etchants.

Common Chemical Etchants for Etching Steel:

- Hydrofluoric Acid (HF) Etchant: Effective for steel and its alloys, requires careful handling due to its corrosive nature.

- Ferric Chloride Etchant: Widely used for etching steel and its alloys, offers good control over etching rates.

- Cupric Chloride Etchant: Suitable for precise and controlled etching of steel materials.

Precautions during Metal Etching Steel:

- Follow safety protocols when handling chemical etchants, including proper ventilation and personal protective equipment.

- Adhere to etching time, temperature, and concentration to achieve precise etching results.

Steel etching equipment

Photo Etching of Steel

Photo etching is a precise and controllable process that uses light-sensitive masks to define patterns on steel surfaces. This technique enables intricate designs and high tolerances.

Etching precision machined steel materials involves understanding the various types, alloys, and their etching characteristics. Electroforming, surface treatment, metal cleansing, and metal etching are integral processes in achieving precise and high-quality steel components. By selecting suitable processes and following necessary precautions, manufacturers can harness the exceptional properties of steel for critical applications across various industries.

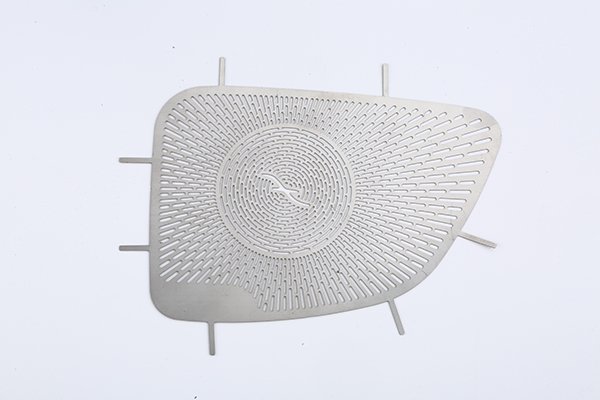

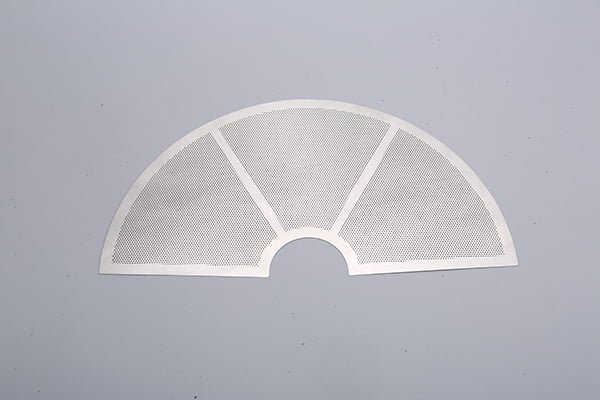

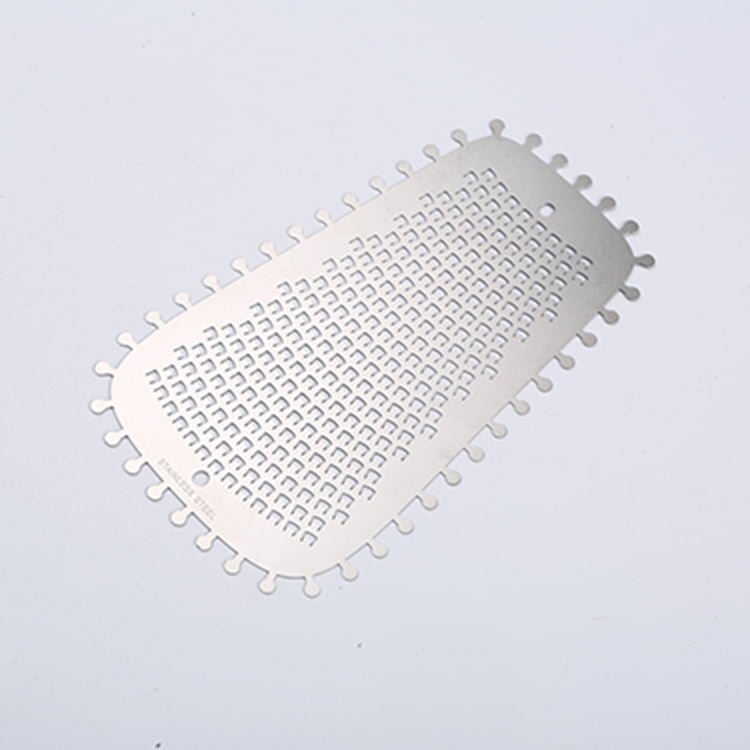

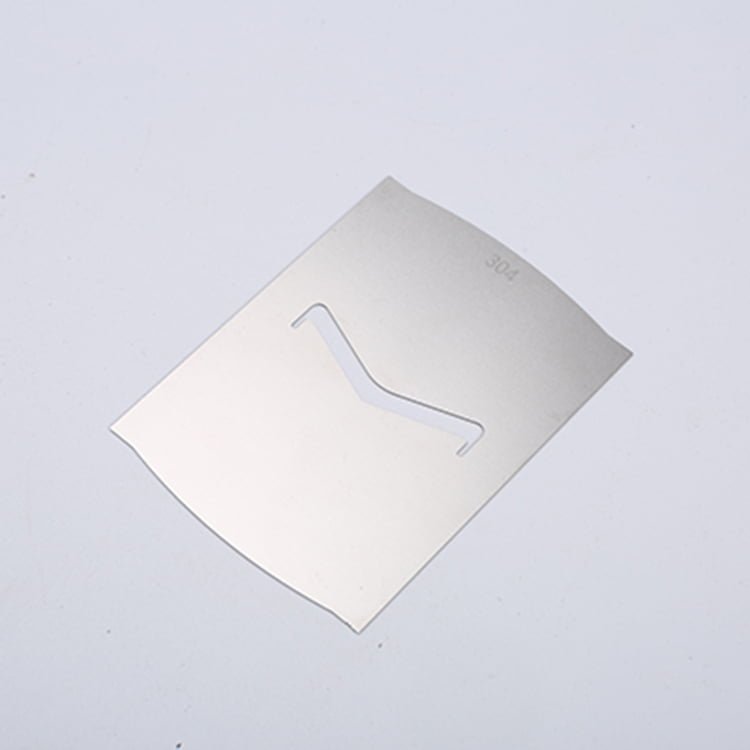

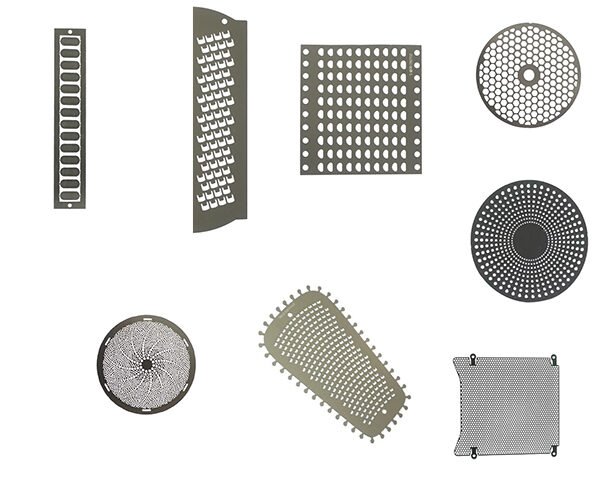

View our metal etching products

how to etch Steel?

Etching Steel Processing Guidelines

| Steel Type | Etchant | Etching Temperature (°C) | Etching Concentration (%) | Estimated Etching Depth (microns) | Etching Quality |

|---|---|---|---|---|---|

| Etching Stainless Steel | Hydrofluoric Acid (HF) | Room temperature | 5% HF | 10-40 | High-quality (smooth) |

| Etching Carbon Steel | Ferric Chloride Etchant | Room temperature | 10% FeCl3 | 10-50 | High-quality (smooth) |

| Etching Tool Steel | Cupric Chloride Etchant | Room temperature | 5% CuCl2 | 10-40 | High-quality (smooth) |

| Etching Alloy Steel | Ferric Chloride Etchant | Room temperature | 10% FeCl3 | 10-50 | High-quality (smooth) |

The values provided are approximate and can vary depending on specific etching conditions, including exposure time and the condition of the steel surface. Always conduct test etches and adjust parameters as needed to achieve your desired results. Additionally, safety precautions should be followed when handling these chemicals, especially in the case of Hydrofluoric Acid.

If you have metal wet etching Steel needs, please feel free to contact us.

FAQs

What metals can you use to customize my goods?

- Wet Etching Germanium

- Wet Etching Gallium Nitride (GaN)

- Wet Etching Indium

- Wet Etching Cobalt

- Wet Etching Tungsten

- Wet Etching Stainless Steel

- Wet Etching Aluminum

- Wet Etching Kovar

- Wet Etching Copper

- Wet Etching Steel

- Wet Etching Nickel

- Wet Etching Platinum

- Wet Etching Silver

- Wet Etching Rhodium

- Wet Etching Hafnium

- Wet Etching Vanadium

- Wet Etching Zirconium

- Wet Etching Titanium

- Wet Etching Niobium

- Wet Etching Tantalum

- Wet Etching Molybdenum

- Wet Etching Brass

- Wet Etching Rhenium

How quickly can I get your response?

Within 24 hours.

Will you do 100% inspection before shipping out the orders?

Yes we do.

Can I have prototypes or samples before placing the order?

Samples are always available.

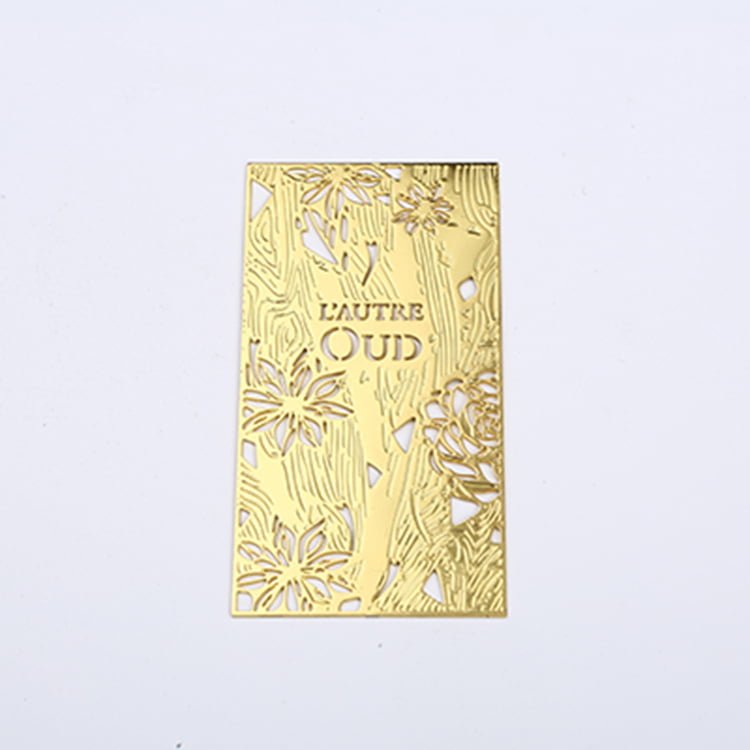

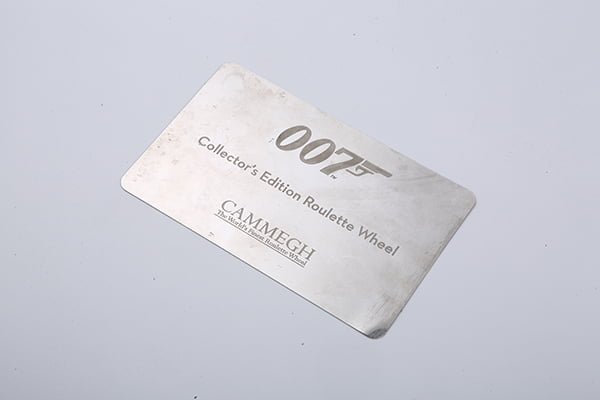

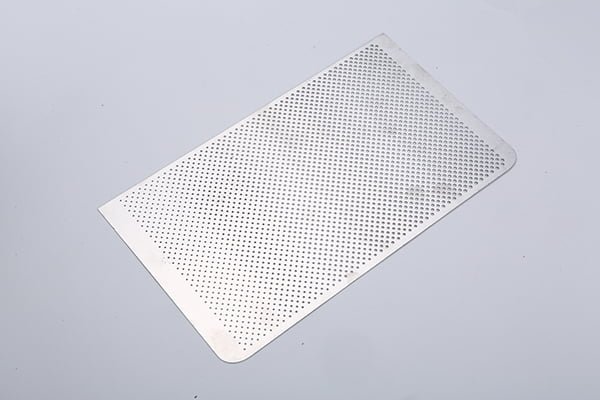

Etching Steel Samples